2205 Duplex Stainless Steel for Pharmaceutical and Biotechnology Applications

Materials of Construction

The pharmaceutical and biotechnology industries have relatively high hygienic requirements, and the construction materials for processing vessels and piping systems must demonstrate outstanding corrosion resistance and cleanability to ensure the purity and integrity of the drug product. Materials must withstand the temperature, pressure, and corrosive nature of the production environments and all sanitizing and cleaning procedures. In addition, candidate materials must have good weldability and be capable of meeting the industry’s surface finish requirements.

The primary construction material for processing equipment in the pharmaceutical and biotechnology industries is Type 316L (UNS S31603, EN 1.4404) austenitic stainless steel. The corrosion resistance, weldability, electropolishing properties, and availability of the 316L grade make it an ideal candidate for most pharmaceutical applications. Although Type 316L performs well in many process environments, users are continually looking to enhance the properties of Type 316L through judicious selection of special 316L chemical compositions and enhanced production processes such as electroslag remelting (ESR).

Figure 1. Pharmaceutical R&D vessel fabricated from 10 gauge 2205 duplex stainless steel sheet and 3/16 inch (4.8 mm) thick 2205 plate. Product contact surfaces were electropolished to an ASME BPE – SF4 finish.

When process environments are too aggressive for Type 316L, users have either accepted the increased maintenance costs of a 316L system or moved to more highly alloyed 6% Mo super austenitic stainless steels such as AL-6XN® (UNS N08367) or 254 SMO® (UNS S31254, EN 1.4547). The biotechnology industry has recently recognized the benefits of constructing processing equipment from Type 2205 (UNS S32205, EN 1.4462) duplex stainless steel.

What is 2205 Duplex Stainless Steel?

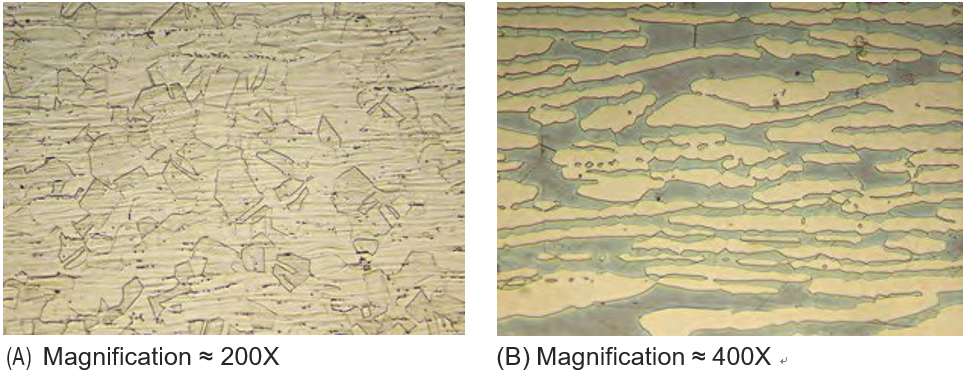

Type 316L stainless steel has a microstructure comprising an austenite phase and a very small volume of ferrite phase. This is achieved primarily by adding sufficient nickel to the alloy to stabilize the austenite phase. The nickel content of wrought 316L stainless steel is typically in the range of 10–11%. Duplex stainless steels have a chemical composition that is adjusted to produce a microstructure that consists of approximately equal parts ferrite and austenite phases (Figure 2). With 2205 duplex stainless steel, this is accomplished by reducing the nickel content to about 5% and adjusting the manganese and nitrogen additions to yield approximately 40–50% ferrite. The chemical composition of the 2205 grade is balanced so that the austenite and ferrite phases have about equal corrosion resistance. “duplex” stainless steel refers to the dual austenite/ferrite microstructure.

The increased nitrogen content and fine-grained microstructure of 2205 duplex stainless steel result in higher strength levels than common austenitic grades such as Types 304L and 316L stainless steel. In the solution-annealed condition, the 2205 grade has about double the yield strength of Type 316L. Depending on the design code used in the construction of the processing facility, this higher strength can result in much higher allowable stresses for the 2205 grade. In many applications, this allows the reduction of the wall thickness, resulting in reduced weight and cost savings.

Figure 2. (A) The microstructure of a wrought Type 316L stainless steel shows austenite grains and an occasional ferrite stringer. (B) The microstructure of a wrought Type 2205 duplex stainless steel shows roughly equal amounts of austenite (light phase) and ferrite (dark phase).

Table 1. Comparison of chemical composition ranges for Type 316L and 2205 stainless steel based on ASTM A 240 requirements*.

| Grade | UNS No. | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| 316L | S31603 | 0.03 | 2.00 | 0.045 | 0.030 | 0.75 | 16.0–18.0 | 10.0–14.0 | 2.0–3.0 | 0.10 |

| 2205 | S32205 | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 22.0–23.0 | 4.5–6.5 | 3.0–3.5 | 0.14–0.20 |

*Maximum unless the range is indicated.

Table 2. Comparison of the mechanical properties of solution-annealed, dual-certified Type 316/316L and 2205 stainless steel according to ASTM A240*.

| Grade | UNS No. | Tensile Strength | Yield Strength | Elongation | Hardness, max | |||

| Ksi | MPa | Ksi | MPa | Brinell | Rockwell | |||

| 316/316L** | S31603 | 75 | 515 | 30 | 205 | 40% | 217 | 95 HRB |

| 2205 | S32205 | 95 | 655 | 65 | 450 | 25% | 293 | 31 HRC |

* Minimum unless otherwise indicated.

** Strength minimum for dual-certified 316/316L; the 316L-only certified grade would have even lower minimum strength requirements.

Corrosion Properties

Pitting Resistance

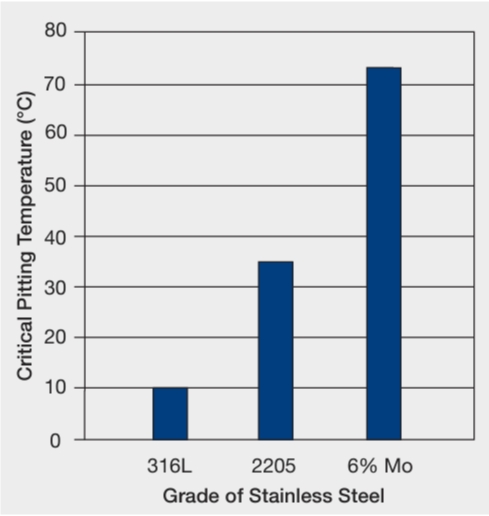

The most common type of corrosion with stainless steel in pharmaceutical and biotechnology applications is pitting in chloride-bearing environments. The increased Cr, Mo, and N levels in 2205 stainless steel provide substantially better pitting and crevice corrosion resistance than that of 316L. The relative pitting resistance of stainless steel can be determined by measuring the temperature required to produce pitting (critical pitting temperature) in a standardized test solution such as 6% ferric chloride. As shown in Figure 3, 2205 has a critical pitting temperature (CPT) between Type 316L and 6% Mo super austenitic stainless steels. It should be noted that the CPTs measured in a ferric chloride solution provide a reliable ranking of the relative chloride pitting resistance but should not be used to predict the critical pitting temperature in other chloride-bearing environments.

Figure 3. Comparison of the critical pitting temperatures measured in a 6% FeCl3 test solution. (Plotted from data reported in reference 1)

Stress-Corrosion Cracking

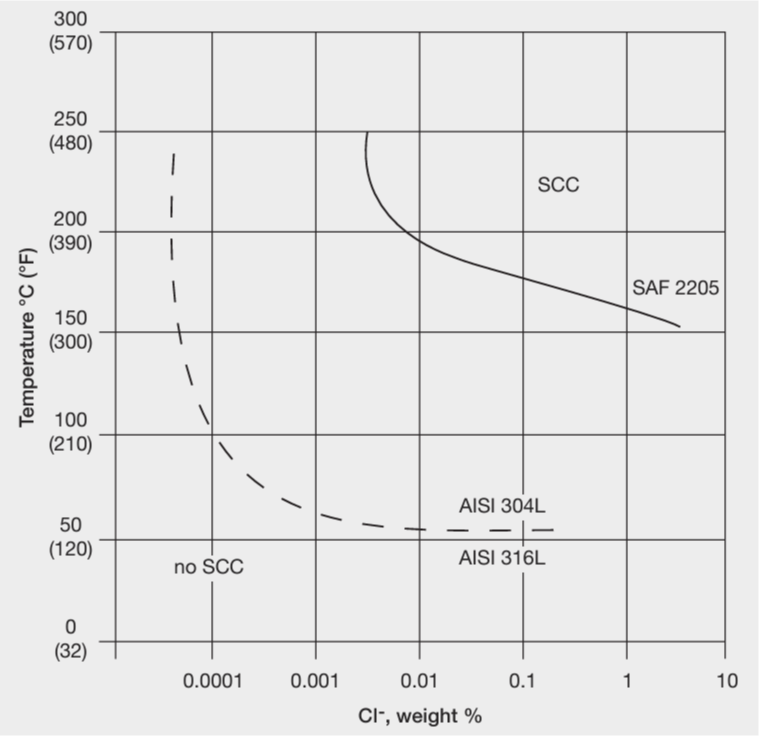

At temperatures above 150°F (60°C), the combination of tensile stresses and chlorides can readily crack the 316L grade. This catastrophic attack mode, termed chloride stress-corrosion cracking (SCC), must be considered when choosing materials for hot process streams. Type 316L should be avoided for applications involving chlorides and temperatures of 150°F (60°C) and higher. As shown in Figure 4, 2205 duplex stainless steel resists SCC in simple salt solutions up to temperatures of at least 250°F (120°C).

Figure 4. Comparison of the chloride stress corrosion cracking thresholds for Type 316L and 2205 duplex stainless steel. (After reference 2, Sandvik’s online 2205 datasheet)

Rouging

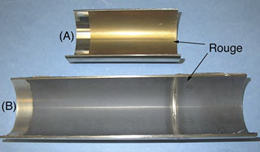

Stainless steels exposed to high-purity water environments can show a thin surface stain or deposit termed rouge or rouging (Figure 5). This staining consists predominantly of ferric oxide or hydroxide particles, which can have a variety of colors, including shades of red, gold, blue, gray, and dark brown. The cause of rouge is poorly understood, and material variables such as the specific grade of stainless steel and surface finish can influence its formation.

Figure 5. Split stainless steel tubing showing a gold-colored (A) and dark gray-colored (B) rouge accumulation on the inside diameter.

In the pharmaceutical and biotechnology industries, clean steam and high-purity water environments encountered in water-for–injection (WFI) systems often show rouge formation. Components such as distillation units, storage tanks, process vessels, pumps, valves, and piping can all be affected.

Because of possible product contamination, heavily rouged surfaces require cleaning, which can be expensive and time-consuming. Therefore, it is important that candidate materials for pharmaceutical and biotechnology applications be at least as resistant to rouge formation as the Type 316L grade. A systematic investigation of rouging has included both 316L stainless steel and 2205 duplex stainless steel (3, 4). Based on this investigation, the 2205 grade is at least as resistant to rouging as the 316L grade.

Fabrication Properties

In many respects, fabrication with 2205 duplex stainless steel is similar to the fabrication with 316L stainless steel. However, there are some essential differences. Cold-forming operations must consider duplex stainless steel’s higher strength and increased work-hardening properties. Higher load capacity may be required for forming equipment, and during forming operations, the 2205 grade will show higher spring-back than the standard austenitic grades. The increased strength also makes the 2205 grade more challenging to machine than Type 316L.

The same welding methods used with Type 316L can be used for joining 2205 duplex stainless steel. However, heat input and interpass temperatures must be closely controlled to maintain desired austenite-ferrite ratios and avoid precipitation of undesirable intermetallic phases. A small amount of nitrogen in the welding gas can be beneficial in avoiding these problems. When qualifying a duplex stainless steel weld procedure, it is common practice to evaluate the austenite-ferrite ratio using either a ferrite gauge or a metallographic examination. The ASTM A 923 test methods are typically used to verify the absence of undesirable intermetallic phases.

Figure 6. Automatic orbital welding of stainless steel tubing

The recommended weld filler is ER2209 (UNS S39209, EN 1600), and welds without filler (autogenous welds) are only recommended if the weld can be solution annealed after welding to restore the corrosion properties. Solution annealing is accomplished by heating to a minimum temperature of 1900°F (1040°C) followed by rapid cooling.

Duplex stainless steels such as 2205 show lower penetration and fluidity than 316L, resulting in lower welding speeds. The reduced penetration of the 2205 grade can require modifying the joint geometry. To achieve full penetration, the 2205 geometries may require wider joint angles, more significant root gaps, and smaller root lands than 316L.

If the welding equipment can accommodate a filler wire, orbital welds for joining 2205 tubes can be made using 2209 filler wire. An appropriate over-alloyed consumable insert can be used as an alternative to filler wire. Table 3 summarizes the insert materials used to join 2205 tubing. Additional guidance on duplex stainless steel pipe and tube welding can be found in Reference (5).

Table 3. Consumable insert materials used to join 2205 tubing

| Insert Materials | Specific Alloys and Grades |

| NiCrMo Alloys | UNS – N06625, N10276, N06022 (EN – 2.4856, 2.4819, 2.4602) |

| 6% Mo Grades | UNS – N08367, S31254, N08926 (EN – NA., 1.4547, 1.4529) |

| Super Duplex Stainless Steel | UNS – S32750, S32760 (EN – 1.4410, 1.4501) |

Electropolishing of Duplex Stainless Steel

Many pharmaceutical and biotechnology applications require product contact surfaces to be electropolished. The ability to achieve a high-quality electropolished surface is an important material characteristic. The 2205 grade can be electropolished to a smoothness of 15 micro-inches (0.38 micro-meters) or smoother, which meets or exceeds the surface finish requirements for electropolished surfaces in the ASME BPE Standard (6). Although 2205 duplex stainless steel can readily meet the pharmaceutical and biotechnology industry’s surface finish requirements, an electropolished 2205 surface is not as bright and lustrous as an electropolished 316L surface. This difference is due to the tendency for slightly higher metal dissolution rates in the ferrite phase compared to the austenite phase during electropolishing.

Specifications and Quality Control Standards

The 2205 grade is covered in various North American and European industry and government standards. Two variations of the 2205 grade are listed in ASTM A 240, S31803, and S32205. The S32205 grade requires slightly higher minimum levels of Cr, Mo, and N but is still within the chemical composition range of S31803. It was developed to address the potential loss of corrosion and toughness properties in the heat-affected zone (HAZ) of some S31803 welds. Because of this, it is recommended that users specify the S32205 grade. If product specifications require the use of the S31803 designation, sometimes required because of its coverage in the ASME code, users should require all S31803 products to have a composition that also meets the requirements for the S32205 designation to obtain the expected consistency of properties.

Table 4 summarizes essential ASTM product and quality control standards for the 2205 grade, and Table 5 lists some relevant international standards for duplex stainless steel. The 2205 grade is included in the most recent edition of the ASME BPE-2009 Standard. Duplex stainless steels are also covered in the API 650 Standard, which specifies the design, materials, fabrication, erection, and testing requirements for vertical, cylindrical, and aboveground tanks.

Table 4. Summary of ASTM product and quality control standards for 2205 duplex stainless steel

| Product Form | Relevant ASTM Specification |

| Forged Pipe Flanges & Fittings | A182 – Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High Temperature Service |

| Plate, Sheet, & Strip | A240 – Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| Seamless & Welded Sanitary Tubing | A270 – Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing |

| Bar & Shapes | A276 – Stainless Steel Bars and Shapes |

| Seamless & Welded Tubing | A789 – Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service |

| Seamless & Welded Pipe | A790 – Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe |

| Pipe Fittings | A815 – Wrought Ferritic, Ferritic/Austenitic, Martensitic Stainless Steel Piping Fittings |

| Welded Pipe | A928 – Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal |

| Castings | A890 – Standard Specification for Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/Ferritic) for General Application

A995 – Standard Specification for Castings, Austenitic-Ferritic (Duplex) Stainless Steel, for Pressure-Containing Parts |

| Quality Control | A923 – Detecting Detrimental Intermetallic Phase in Duplex (Austenitic/Ferritic) Stainless Steels |

| Corrosion Testing | G48 – Standard Test Method for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution |

Table 5. Applicable European material standards

| EN 10028-7 | Flat products for pressure purposes – Stainless steel |

| EN 10088-2 | Stainless steels – Corrosion-resisting sheet/plate/strip for general and construction purposes |

| EN 10088-3 | Stainless steels – Corrosion-resisting semi-finished products/bars/rods/wire/sections for general and construction purposes |

| EN 10217-7 | Welded steel tubes for pressure purposes – Stainless steel tubes |

| EN 10272 | Stainless steel bars for pressure purposes |

| EN 10296-2 | Welded circular steel tubes for mechanical and general engineering purposes – Stainless steel tubes |

| VdTÜV WB 418 | Ferritisch-austenitischer Walz- und Schmiedestahl, 1.4462 |

| Norsok M-CR 630, MDS D45 | Piping material data sheets for duplex stainless steel |