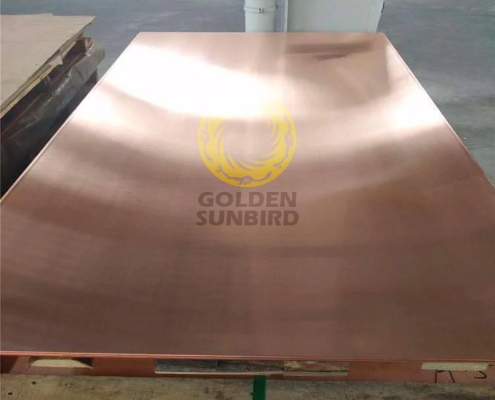

Golden Sunbird Metals is a professional copper alloy plate and sheet supplier from China. specializes in copper alloy plates and sheets renowned for their superb conductivity and corrosion resistance. Ideal for applications ranging from electrical components and architectural elements to marine and automotive industries, our products are available at wholesale prices. We offer a vast in-stock selection and custom manufacturing to meet specific requirements from UNS C10000 through UNS C79999 grades. If you are interested in purchasing copper alloy plates and sheets in bulk or need a tailored solution for your copper alloy needs, please do not hesitate to contact us at [email protected]. We are here to fulfill all your copper alloy requirements with precision and quality.

FAQs

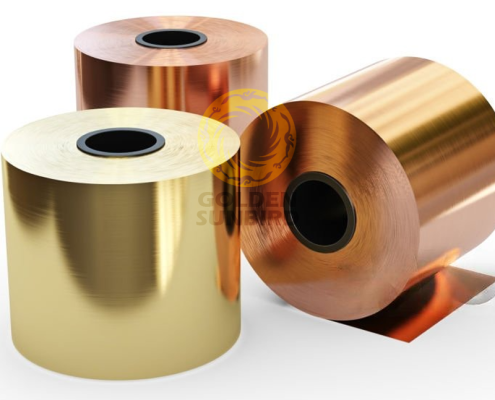

What types of copper alloys are available in plate and sheet form?

Various types of copper alloys are available in plate and sheet form, including brass, bronze, copper-nickel, and nickel-silver. Each alloy has unique properties tailored to specific applications, such as high strength, corrosion resistance, or electrical conductivity.

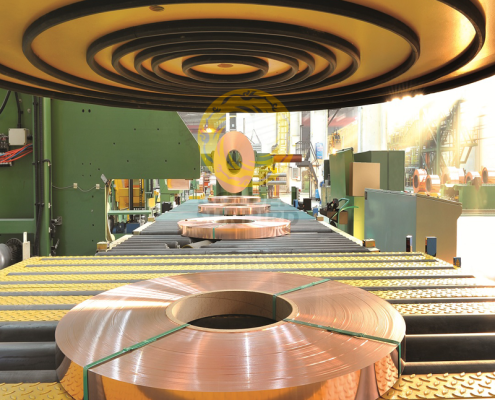

How are copper alloy plate and sheet products manufactured?

Copper alloy plate and sheet products are typically manufactured through processes such as casting, rolling, or extrusion. These processes involve melting the metals, forming them into the desired shape, and then cooling and finishing the products to meet specified dimensions and surface quality.

Are copper alloy plate and sheet products recyclable?

Yes, copper alloy plate and sheet products are highly recyclable. Copper is one of the most recycled metals in the world, with a high value in the recycling market. Recycling copper alloys helps conserve natural resources, reduce energy consumption, and minimize environmental impact.

Can copper alloy plate and sheet products be customized to specific dimensions?

Yes, many suppliers offer custom fabrication services for copper alloy plate and sheet products. This allows customers to order materials in precise dimensions tailored to their application requirements.

What surface finishes are available for copper alloy plate and sheet products?

Copper alloy plate and sheet products can be provided with various surface finishes, including mill finish, brushed, polished, and coated finishes. The choice of finish depends on aesthetic preferences and functional requirements.

Can copper alloy plate and sheet products be welded or soldered?

Yes, most copper alloys can be welded or soldered using appropriate techniques and filler materials. However, it’s essential to follow recommended procedures to avoid compromising the mechanical properties or corrosion resistance of the material.

Are there any regulatory standards or certifications that copper alloy plate and sheet products must meet?

Depending on the industry and application, copper alloy plate and sheet products may need to comply with specific regulatory standards or certifications, such as ASTM, ISO, or MIL-SPEC requirements. Suppliers can provide documentation verifying compliance with applicable standards.

How do I calculate the weight of copper alloy plate and sheet products?

The weight of copper alloy plate and sheet products can be calculated using their dimensions (length, width, thickness) and the density of the specific alloy. Online calculators or formulas provided by suppliers can assist in determining the weight of materials for planning and transportation purposes.

Can copper alloy plate and sheet products be coated or plated with other metals?

Yes, copper alloy plate and sheet products can be coated or plated with other metals such as nickel, chrome, or zinc to enhance surface properties such as hardness, corrosion resistance, or aesthetics. Electroplating and other surface treatment methods are commonly used for this purpose.

Can copper alloy plate and sheet products be machined or fabricated using standard tools and equipment?

Yes, copper alloy plate and sheet products can generally be machined, drilled, bent, and formed using standard tools and equipment found in metalworking shops. However, specific machining parameters and cutting fluids may be required to achieve optimal results.

Are copper alloy plate and sheet products susceptible to galvanic corrosion when in contact with other metals?

Yes, copper alloy plate and sheet products can experience galvanic corrosion when in contact with dissimilar metals in the presence of an electrolyte (such as moisture or saltwater). Proper insulation, coating, or the use of compatible materials can help mitigate this risk in mixed-metal assemblies.