Golden Sunbird Metals is a professional supplier of titanium and titanium alloy plates and sheets in China. We offer wholesale prices of high-quality titanium and titanium alloy plates and sheets. Our products are utilized in various industries due to their high strength, low weight, and corrosion resistance, such as aerospace for aircraft structures, marine shipbuilding, chemical processing equipment, medical implants, high-performance automotive components, desalination plants, architectural cladding, power plant condensers, and offshore oil and gas platforms. We can perform precision cutting, drilling, stamping of complex-shaped parts, explosion cladding, and machining to meet your customized requirements. If you want to buy titanium and titanium alloy plates and sheets in bulk or are looking for a customized titanium and titanium alloy plate and sheet solutions company, please feel free to contact [email protected].

FAQs

What Is Titanium Plate and Sheet?

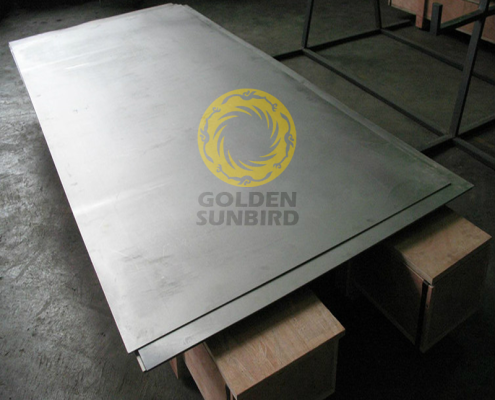

Titanium plate and sheet are forms of titanium metal that have been processed into thin, flat pieces. They are distinguished by their thickness, with plates being thicker than sheets. This form of titanium is highly sought after for its strength-to-weight ratio, corrosion resistance, and biocompatibility. It’s utilized in applications that require materials to withstand extreme conditions without failure.

- Titanium plates and sheets are thin, flat pieces of titanium.

- Plates are thicker than sheets.

- They offer high strength, corrosion resistance, and are biocompatible.

How Are Titanium Plate and Sheet Manufactured?

The manufacturing process of titanium plate and sheet involves several steps. It starts with the extraction of titanium from its ores, followed by purification and reduction to produce titanium sponge. This sponge is then melted in a vacuum or argon environment to create ingots. The ingots are heated and rolled into plates or sheets at high temperatures. The process may include annealing to improve ductility and finishing steps to achieve the desired surface quality.

- Extraction from ores, followed by purification and reduction.

- Melting of titanium sponge to produce ingots.

- Heating and rolling ingots into plates or sheets.

What Are the Applications of Titanium Plate and Sheet?

Titanium plate and sheet are used in a wide range of applications due to their exceptional properties. In aerospace, they are used for aircraft structures and engine components, benefiting from their strength and lightweight. In the medical field, titanium plates are used for surgical implants, thanks to their biocompatibility. Additionally, in the marine industry, they are chosen for their corrosion resistance, used in shipbuilding and offshore platforms.

- Aerospace industry for aircraft structures and engine components.

- Medical field for surgical implants.

- Marine industry for shipbuilding and offshore platforms.

Can Titanium Plate and Sheet Be Welded?

Yes, titanium plate and sheet can be welded, but it requires specific techniques to prevent contamination. Titanium is highly reactive at elevated temperatures, so welding must be performed in an inert atmosphere, typically using argon shielding gas, to prevent oxygen, nitrogen, and hydrogen contamination. For best results, welding should be done by experienced personnel using methods like Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG) welding.

- Welding is possible in an inert atmosphere.

- TIG and MIG welding methods are commonly used.

- Requires skilled personnel to prevent contamination.

Are There Different Finishes Available for Titanium Plate and Sheet?

Yes, titanium plate and sheet are available in a variety of finishes, ranging from mill finish (which is as-rolled and may contain marks from manufacturing) to more refined surfaces. Surface treatments can include sandblasting, brushing, or polishing to achieve a specific aesthetic or functional finish. The choice of finish will depend on the application requirements, whether for enhancing corrosion resistance, reducing light reflection, or for cosmetic purposes.

- Variety of finishes available.

- Surface treatments like sandblasting, brushing, or polishing.

- Choice depends on application requirements.