AMS4910 Ti5Al2.5Sn Titanium Alloy Plate and Sheet

- Ti5Al2.5Sn

- Annealed condition

- Composition

- Strength and Toughness

- Temperature Resistance

- Corrosion Resistance

- Weldability and Formability

Features

AMS4910 Ti5Al2.5Sn Titanium Alloy, Sheet, Strip, And Plate 5Al-2.5Sn Annealed

Chemical Composition (wt.%)

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | 4.50 – 5.75 |

| Tin (Sn) | 2.00 – 3.00 |

| Iron (Fe) | Max 0.50 |

| Oxygen (O) | Max 0.20 |

| Carbon (C) | Max 0.08 |

| Nitrogen (N) | Max 0.05 (500 ppm) |

| Hydrogen (H) | Max 0.020 (200 ppm) |

| Yttrium (Y) | Max 0.005 (50 ppm) |

| Other elements, each | Max 0.10 |

| Other elements, total | Max 0.40 |

| Titanium (Ti) | Remainder |

Mechanical Properties (Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | 828 – 1034 MPa (120,000 – 150,000 psi) |

| Yield Strength (0.2% Offset) | 759 – 1034 MPa (110,000 – 150,000 psi) |

| Elongation (in 4D) | 10% – 20% |

| Reduction of Area | 20% – 30% |

| Modulus of Elasticity | About 110 GPa (16 x 10^6 psi) |

| Density | 4.48 g/cm^3 |

Technical Specifications

| Specification | Value |

| Standard | AMS4910 Ti5Al2.5Sn Titanium Alloy, Sheet, Strip, And Plate 5Al-2.5Sn Annealed. |

| Grade | Ti5Al2.5Sn |

| Melting Practice | The alloy shall be melted multiple times. The first melt shall be made using a vacuum consumable electrode, non-consumable electrode, electron beam cold hearth, or plasma arc cold hearth melting practice. The subsequent melt or melts shall be made using vacuum arc remelting (VAR) practice. Alloy additions are not permitted in the final VAR melt. |

| Type | Titanium Sheet, Strip, and Plate |

| Dimension | Strip: Width 25.4-1219.2mm x Thickness 0.41-4.75mm |

| Sheet: Width 1000-2000mm x Thickness 0.41-4.75mm | |

| Plate: Width 1000-2000mm x Thickness 4.75-101.6mm | |

| Density | 4.48g/cm³ |

| Condition | Sheet and Strip: Hot rolled with or without subsequent cold reduction, annealed, descaled, and leveled, having a surface appearance comparable to a commercial corrosion-resistant steel No. 2D finish. Plate: Hot rolled, annealed, descaled, and flattened, having a surface appearance comparable to a commercial corrosion-resistant steel No. 1 finish. Plate products shall be produced using standard industry practices designed strictly for producing plate stock to the procured thickness. Bar, billet, forgings, or forging stock shall not be supplied in lieu of plate. |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Composition, Mechanical Properties |

Key Features

Composition: 5% aluminum, 2.5% tin, with the rest titanium.

Strength and Toughness: Offers a robust strength-to-weight ratio and good toughness.

Temperature Resistance: Maintains mechanical properties up to 400-450°C (752-842°F).

Corrosion Resistance: Highly resistant to corrosion and oxidation.

Weldability and Formability: Good weldability and formability for various fabrication processes.

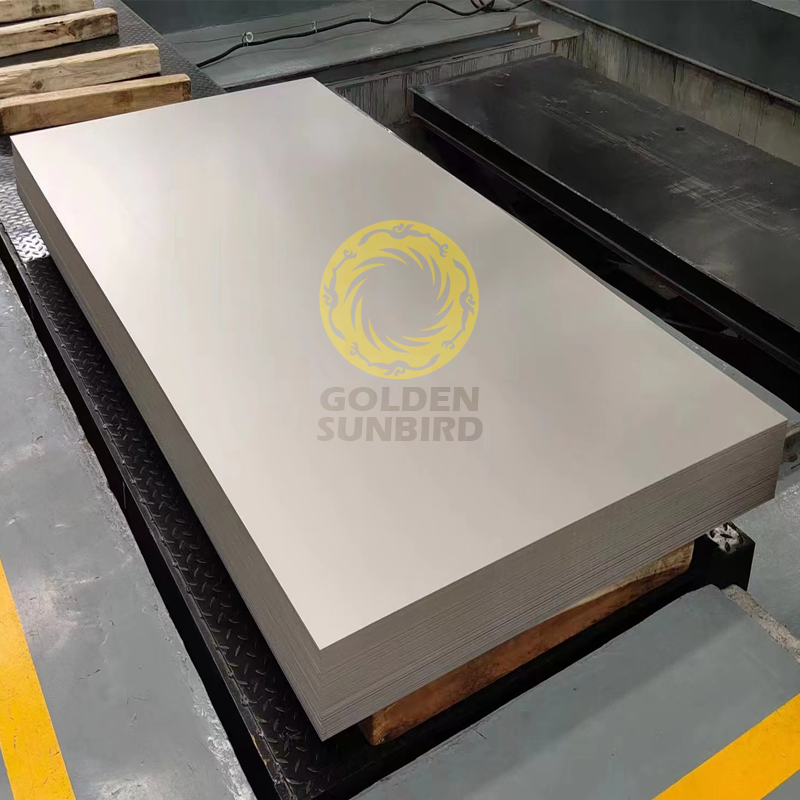

Packing

Packed in plywood boxes or on pallets.

Application

Airframe Components: Due to its high strength-to-weight ratio and corrosion resistance, Ti-5Al-2.5Sn is used in airframe structures and components where durability and reliability are critical.

Engine Parts: Components within aircraft engines that require high strength at elevated temperatures, such as compressor blades, discs, and rings, can be made from this alloy.

Hydraulic Systems: The alloy’s good fatigue strength and toughness make it suitable for aircraft and spacecraft hydraulic system components and fittings.

Submarine Parts: Its excellent corrosion resistance in seawater makes it ideal for various submarine components.

Marine Hardware: Used in marine hardware and components exposed to corrosive marine environments.

Process Equipment: Due to its excellent corrosion resistance, Ti-5Al-2.5Sn is used in chemical processing equipment such as reactors, heat exchangers, and piping systems.

Orthopedic Implants: The ELI (Extra Low Interstitial) version of Ti-5Al-2.5Sn is also used in the medical industry for manufacturing orthopedic implants due to its excellent biocompatibility and strength.

Cryogenic Containers and Equipment: The alloy maintains its toughness and strength at cryogenic temperatures, making it suitable for containers and structures for storing and transporting liquefied gases.