AMS4965 Ti6Al4V Titanium Alloy Bars, Wire, Forgings, and Rings

- Grade: Ti6Al4V, Grade 5

- Annealed condition

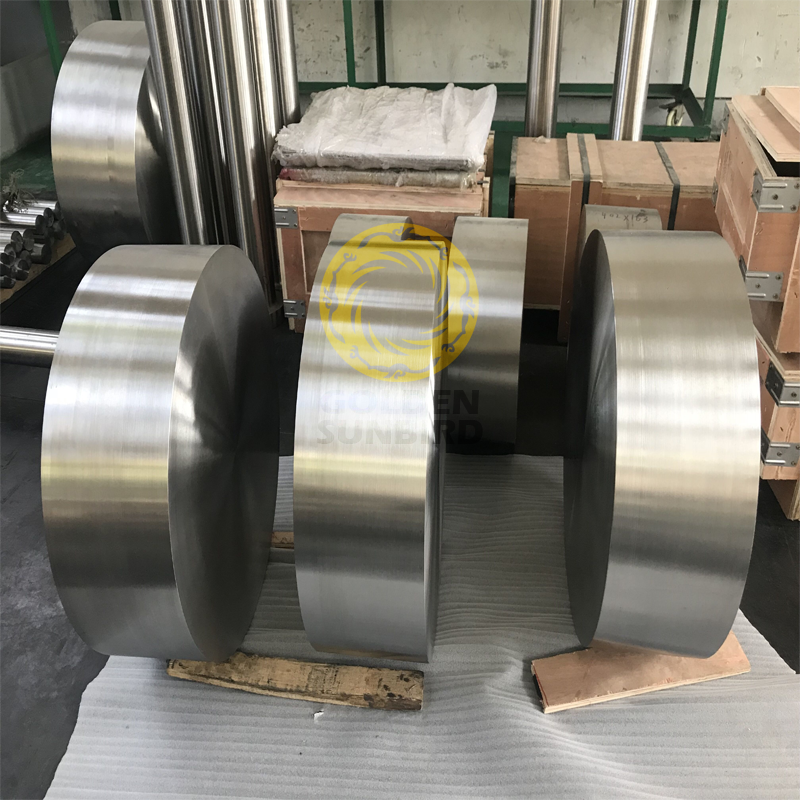

- Bar, Rings, Forgings

- High Strength and Fatigue Resistance

- Good Corrosion Resistance

- Lightweight

- Good Biocompatibility

- Heat Treatability

Features

AMS4965 Ti6Al4V Titanium Alloy Bars, Wire, Forgings, and Rings Solution Heat Treated and Aged

AMS4965 Ti6Al4V Chemical Composition (wt.%)

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | 5.50 – 6.75 |

| Vanadium (V) | 3.50 – 4.50 |

| Iron (Fe) | Max 0.30 |

| Oxygen (O) | Max 0.20 |

| Carbon (C) | Max 0.08 |

| Nitrogen (N) | Max 0.05 (500 ppm) |

| Hydrogen (H) | Max 0.0125 (125 ppm) |

| Yttrium (Y) | Max 0.005 (50 ppm) |

| Other Elements, each | Max 0.10 |

| Other Elements, total | Max 0.40 |

| Titanium (Ti) | Remainder |

AMS4965 Ti6Al4V Mechanical Properties (Minimum)

| Property | Value |

|---|---|

| Tensile Strength (ksi) | 130 – 165 |

| Yield Strength (ksi) | 120 – 155 |

| Elongation (%) | 6 – 10 |

| Reduction of Area (%) | 20 – 25 |

Technical Specifications

| Specification | Value |

| Standard | AMS4965 Ti6Al4V Titanium Alloy Bars, Wire, Forgings, and Rings Solution Heat Treated and Aged |

| Grade | Ti6Al4V, Grade 5 |

| Type | Bar, Wire, Forgings, Rings |

| Dimension | Bar Dia: 0.25 to 12 inches (6.35 to 304.8 mm), Length up to 20 feet (6096 mm) |

| Wire Dia: 0.020 to 0.500 inches (0.51 to 12.7 mm) | |

| Block: Width: 2 – 24 inches (50 -610mm) x Height: 2 – 24 inches (50-610mm) x Length: 2 – 20 feet (610-6100mm) | |

| Rings: OD: 250-1500mm, ID: 150-1400mm, Height: 20-500mm | |

| Density | 4.51g/cm³ |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Composition, Mechanical Properties |

Key Features

High Strength and Fatigue Resistance: Ti-64 exhibits high strength and fatigue resistance, making it suitable for structural components and cyclic loading applications.

Good Corrosion Resistance: It demonstrates good resistance to corrosion in various environments, including seawater, chloride solutions, and some acids.

Lightweight: Ti-64 retains the lightweight characteristic of titanium alloys, contributing to weight savings in components and structures.

Good Biocompatibility: It exhibits good biocompatibility, making it suitable for medical implants and devices.

Heat Treatability: Ti-64 can be heat treated to enhance its strength and other mechanical properties further.

Packing

Packed in plywood boxes.

Applications in Bar Form:

Aircraft structural components: These are used for spars, ribs, fasteners, and other structural parts requiring a high strength-to-weight ratio and fatigue resistance.

Surgical instruments: Employed for scalpels, forceps, and other instruments requiring biocompatibility, strength, and corrosion resistance.

Shafts and fasteners: Utilized for shafts, fasteners, and other components exposed to corrosive chemicals.

High-performance parts: Used for connecting rods, valves, and other parts requiring high strength and low weight.

Applications in Forged Form:

Landing gear components: Forged Ti-64 is used for landing gear components like struts and wheels due to its high strength and fatigue resistance.

Engine mounts and structural parts: Employed for complex shaped components requiring high strength and durability.

Armour plating and structural components: These are used in military vehicles and equipment for their strength, lightweight, and ballistic resistance.

Joint replacements: Forged Ti-64 is a common material for hip, knee, and other joint replacements due to its strength, wear resistance, and biocompatibility.

Applications in Ring Form:

Jet engine components: These are forged and machined into compressor rings, spacers, and other engine parts requiring high strength and fatigue resistance.

Bearings and seals: These are used for bearing races, seal rings, and other components that need wear and corrosion resistance.