ASME B16.5 Stainless Steel Pipe Flanges

- Flange Standard: ASME B16.5

- Material Standard: ASTM A182/A182M

- Dimensions: NPS 1/2″- 24″

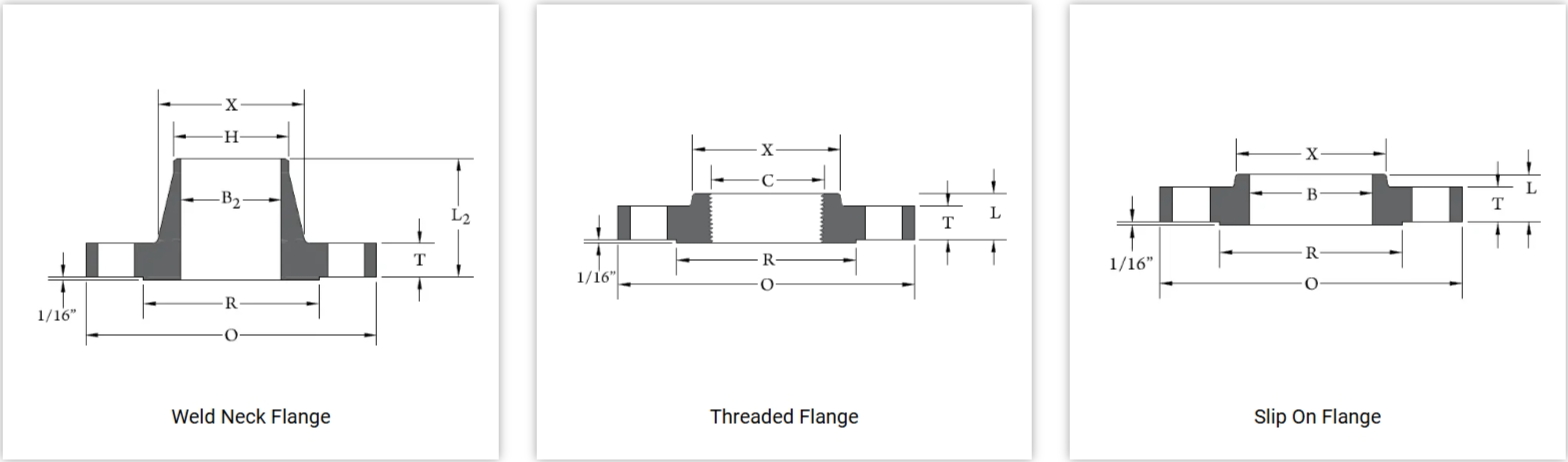

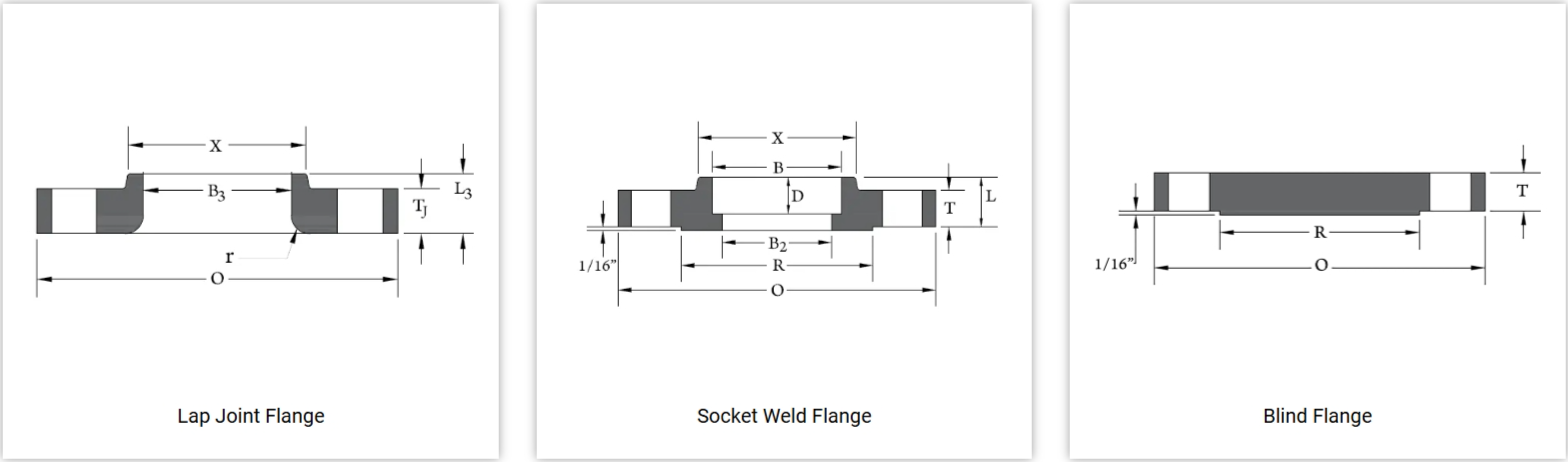

- Flange Types: Weld Neck, Blind, Slip-On, Threaded, Socket Weld, Lap Joint

- Face Types: RF=Raised Face, FF=Flat Face, RTJ=Ring Type Joint, M&F=Male-and-Female, T&G=Tongue-and-Groove

- Pressure Rating: 150LBS, 300LBS, 400LBS, 600LBS, 900LBS, 1500LBS, 2500LBS

Features

ASME B16.5 Stainless Steel Pipe Flanges

Technical Specifications

| Specification | Value |

| Standard | ASME B16.5 Stainless Steel Pipe Flanges |

| Material | Standard: ASTM A182/A182M Grade: F304, F304H, F304L, F309H, F310, F310H, F310MoLN, F316, F316H, F316L, F316Ti, F317, F317L, F321, F321H, F347, F347H, F348, F348H, F20, F44, F45, F46, F47, F48, F49, F56, F58, F62, F63, F64, F904L, F50, F51, F52, F53, F54, F55, F57, F59, F60, F61, F65, F66, and F67 |

| Face Types | RF=Raised Face, FF=Flat Face, RTJ=Ring Type Joint, M&F=Male-and-Female, T&G=Tongue-and-Groove |

| MFG. Process | Forged or Rolled |

| Flange Types | Weld Neck, Blind, Slip-on, Threaded, Socket Weld, Lap Joint |

| Working Pressure | 150LBS, 300LBS, 400LBS, 600LBS, 900LBS, 1500LBS, 2500LBS |

| Dimension | NPS 1/2″-24″, WT: SCH 5S, 10S, 40S, 80S, XS, XXS |

| Flange standard | ASME B16.5 |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Analysis, Tensile Test, UT/ET |

Packing

Small diameter packed in plywood box; large diameter packed on plywood pallets.

Application

Oil and Gas Industry

Pipelines and Flow Lines: Used in high-pressure pipelines and flow lines for transporting crude oil, natural gas, and other hydrocarbons.

Refineries: These are employed in various refinery units where corrosion resistance and high-temperature capabilities are essential, such as catalytic cracking units, reformers, and distillation units.

Offshore Platforms: Used in subsea and topside equipment where exposure to harsh marine environments requires robust and reliable connections.

Chemical and Petrochemical Industry

Chemical Processing Plants: Ideal for connecting pipes in chemical processing systems due to their resistance to a wide range of chemicals and corrosive environments.

Storage Tanks: These are used to construct and maintain storage tanks for corrosive substances.

Reactors and Heat Exchangers: These are employed in reactors and heat exchangers where high strength and corrosion resistance are critical.

Power Generation

Nuclear Power Plants: These are used in critical components such as reactor coolant systems, steam generators, and feedwater systems where materials must withstand high radiation and temperature.

Thermal Power Plants: They are utilized in boilers, turbines, and heat recovery systems and must endure high temperatures and pressures.

Renewable Energy: Applied in geothermal and solar power plants for their durability and resistance to extreme conditions.

Food and Beverage Industry

Processing Equipment: Used in food processing and beverage production equipment, hygiene and corrosion resistance are vital.

Piping Systems: Piping systems are employed in piping systems that handle water, juices, dairy products, and other consumables.

Pharmaceutical Industry

Production Facilities: These are used in constructing production facilities where cleanliness, sterility, and resistance to corrosion from various chemicals are crucial.

Bioreactors and Mixing Vessels: Ideal for bioreactors and mixing vessels due to their ability to maintain sterile environments.

Water Treatment and Desalination

Water Treatment Plants: These are used in the piping systems of water treatment plants due to their resistance to corrosion and long-term durability.

Desalination Plants: Essential in desalination plants where saltwater resistance is required.

Marine Industry

Shipbuilding: Used in various shipbuilding applications, including piping systems, ballast systems, and fuel systems where exposure to seawater demands corrosion-resistant materials.

Offshore Drilling Rigs: Employed in offshore drilling rigs for connecting pipes and equipment exposed to harsh marine environments.

Construction and Infrastructure

Structural Applications: Used in structural applications where high strength and corrosion resistance are necessary.

Water and Gas Distribution: Employed in municipal water and gas distribution systems due to their longevity and reliability.