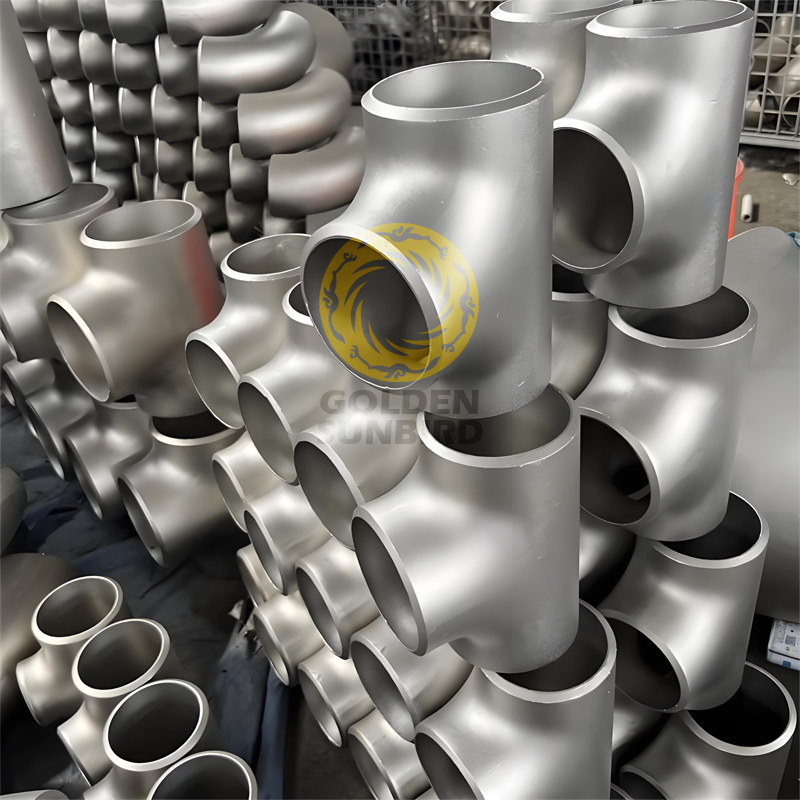

ASTM A403 Austenitic Stainless Steel Piping Fittings

- Type: Seamless and Welded Butt-welding Fittings

- Size: NPS 1/8″ – 48″ WT: SCH5S, 10S, 40S, 80S

- Standard: ANSI/ASME B16.9, MSS SP-43, MSS SP-97

- 45° and 90° Elbows, 180° Bends, Caps, Tees, Reducers, Lap-joint Stub Ends, and other types

Features

ASTM A403/A403M Wrought Austenitic Stainless Steel Piping Fittings

Table 1: Fitting Classes for WP Grades

| Class | Construction | Nondestructive Examination |

| S | Seamless | None |

| W | Welded | Radiography or Ultrasonic |

| WX | Welded | Radiography |

| WU | Welded | Ultrasonic |

Table 2: Chemical Requirements

| Grade | UNS Designation | C | Mn | P | S | Si | Ni | Cr | Mo | Ti | N | Others |

| WPXM-19 | S20910 | 0.06 | 4.0-6.0 | 0.045 | 0.030 | 1.00 | 11.5-13.5 | 20.5-23.5 | 1.50-3.00 | None | 0.20-0.40 | None |

| WP304 | S30400 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | None | None | None | None |

| WP304L | S30403 | 0.03 | 2.0 | 0.045 | 0.030 | 1.00 | 8.0-12.0 | 18.0-20.0 | None | None | None | None |

| WP304H | S30409 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | None | None | None | None |

| WP304N | S30451 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | None | None | 0.10-0.16 | None |

| WP304LN | S30453 | 0.03 | 2.0 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | None | None | 0.10-0.16 | None |

| WP309 | S30900 | 0.2 | 2.0 | 0.045 | 0.030 | 1.00 | 12.0-15.0 | 22.0-24.0 | None | None | None | None |

| WP310S | S31008 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 19.0-22.0 | 24.0-26.0 | None | None | None | None |

| WPS31254 | S31254 | 0.02 | 1.0 | 0.03 | 0.010 | 0.80 | 17.5-18.5 | 19.5-20.5 | 6.0-6.5 | None | 0.18-0.22 | Cu 0.50-1.00 |

| WP316 | S31600 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | None | None | None |

| WP316L | S31603 | 0.03 | 2.0 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | None | None | None |

| WP316H | S31609 | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | None | None | None |

| WP316N | S31651 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | None | 0.10-0.16 | None |

| WP316LN | S31653 | 0.03 | 2.0 | 0.045 | 0.030 | 1.00 | 10.0-13.0 | 16.0-18.0 | 2.00-3.00 | None | 0.10-0.16 | None |

| WP317 | S31700 | 0.08 | 2.0 | 0.045 | 0.030 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | None | None | None |

| WP317L | S31703 | 0.03 | 2.0 | 0.045 | 0.030 | 1.00 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | None | None | None |

Table 3: Common Names

| UNS Designation | Common Name |

| S20910 | XM-19 |

| S30400 | 304 |

| S30403 | 304L |

| S30409 | 304H |

| S30451 | 304N |

| S30453 | 304LN |

| S30900 | 309 |

| S31008 | 310S |

| S31254 | S31254 |

| S31600 | 316 |

| S31603 | 316L |

| S31609 | 316H |

| S31651 | 316N |

| S31653 | 316LN |

| S31700 | 317 |

| S31703 | 317L |

Table 4: Mechanical Test Requirements

| Grade | Tensile Strength, min, ksi [MPa] | Yield Strength, min, ksi [MPa] | Elongation in 2 in. or 50 mm, min, % | |

| Longitudinal | Transverse | |||

| WPXM-19 | 100 [690] | 60 [415] | 28 | 20 |

| WP304 | 75 [515] | 30 [205] | 28 | 20 |

| WP304L | 70 [485] | 25 [170] | 28 | 20 |

| WP304H | 75 [515] | 30 [205] | 28 | 20 |

| WP304N | 75 [515] | 30 [205] | 28 | 20 |

| WP304LN | 75 [515] | 30 [205] | 28 | 20 |

| WP309 | 80 [550] | 30 [205] | 28 | 20 |

| WP310S | 75 [515] | 30 [205] | 28 | 20 |

| WPS31254 | 100 [690] | 45 [310] | 28 | 20 |

| WP316 | 75 [515] | 30 [205] | 28 | 20 |

| WP316L | 70 [485] | 25 [170] | 28 | 20 |

| WP316H | 75 [515] | 30 [205] | 28 | 20 |

| WP316N | 75 [515] | 30 [205] | 28 | 20 |

| WP316LN | 75 [515] | 30 [205] | 28 | 20 |

| WP317 | 75 [515] | 30 [205] | 28 | 20 |

| WP317L | 70 [485] | 25 [170] | 28 | 20 |

Technical Specifications

| Specification | Value |

| Material Standard | ASTM A403/A403M Wrought Austenitic Stainless Steel Piping Fittings |

| Material Grade | WPXM-19, WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L |

| Seam Type | Seamless and Welded |

| O.D. | 10.3- 1219mm (NPS 1/8″ – 48″) |

| W.T. | 1.65- 30.96mm (0.065″-1.219″) SCH 5S, SCH5, SCH10S, SCH10, SCH40S, SCH40, SCH80S, SCH80 |

| Type of Fittings | 45° LR and 90° SR/LR Elbows, 180° Returns, Caps, Equal or Reducing Tees, Concentric/Eccentric Reducers, Lap-joint Stub Ends |

| Manufacturing Process | Butt-welded |

| Fitting Standard and Ends Finish | ASME B16.9, MSS SP-43, and MSS SP-97. |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Analysis, Tensile Test, UT/ET, Dimensional Inspection |

Packing

Plain or beveled ends as per ANSI B16.25 to an angle of 30°+5°/-0°, end with plastic caps or metal protectors, covered or bare, bundled or loosely packed.

Application

Chemical Processing: This is used to handle corrosive chemicals due to their high corrosion resistance.

Petroleum Refining: In pipelines and processing units to withstand high temperatures and corrosive environments.

Food and Beverage Processing: Ensuring hygienic and non-contaminating transport of products.

Pharmaceutical Manufacturing: Maintaining sanitary conditions in processing equipment.

Power Generation: In both conventional and nuclear plants, for high temperature and pressure applications.

Oil and Gas: For offshore and onshore applications, providing reliability in extreme conditions.

Water Treatment: Used in systems that require corrosion-resistant materials.

Marine Applications: In shipbuilding and offshore platforms due to their resistance to seawater corrosion.

Pulp and Paper Industry: For processing equipment requiring high durability and chemical resistance.

Construction: For various structural applications where strength and durability are crucial.