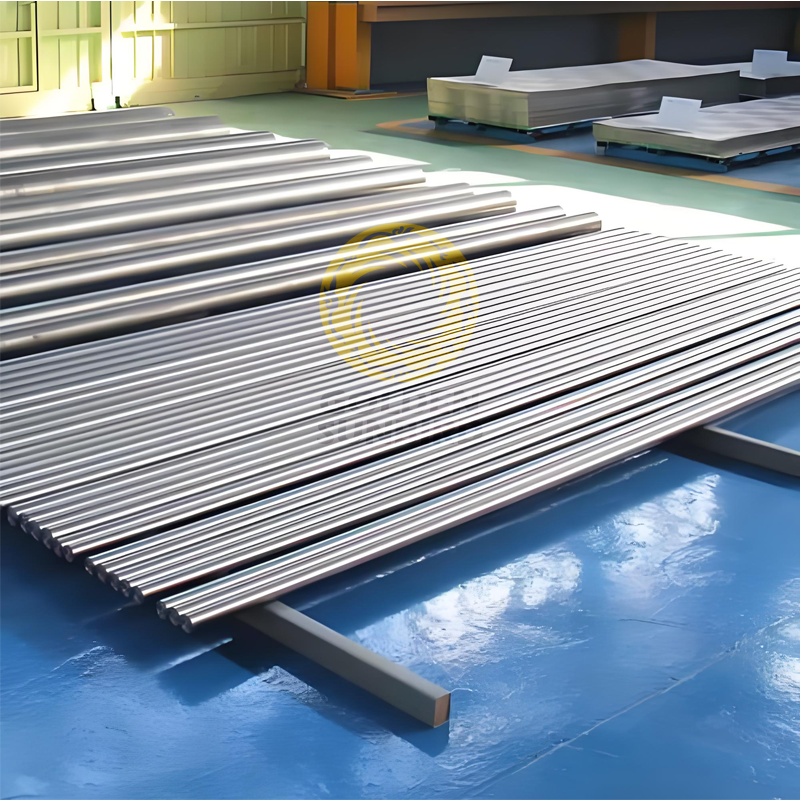

ASTM A564 Age-Hardening Stainless Steel Bars

- Grade: 630 (S17400), 631 (S17700), 632 (S15700), 634 (S35500), 635 (S17600), XM-12 (S15500), XM-13 (S13800), XM-16 (S45500), and XM-25 (S45000)

- Manufacturing Methods: Hot-finished or cold-finished

- Shapes: Rounds, Squares, Hexagons, Bar shapes, Angles, Tees, and Channels

Features

ASTM A564/A564M Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes

Chemical Composition (wt.%)

| UNS No. | Type | C (max) | Mn (max) | P (max) | S (max) | Si (max) | Cr | Ni | Al | Mo | Ti | Cu |

| S17400 | 630 | 0.07 | 1.00 | 0.04 | 0.03 | 1.00 | 15.00-17.50 | 3.00-5.00 | – | – | – | 3.00-5.00 |

| S17700 | 631 | 0.09 | 1.00 | 0.04 | 0.03 | 1.00 | 16.00-18.00 | 6.50-7.75 | 0.75-1.50 | – | – | – |

| S15700 | 632 | 0.09 | 1.00 | 0.04 | 0.03 | 1.00 | 14.00-16.00 | 6.50-7.75 | 0.75-1.50 | 2.00-3.00 | – | – |

| S35500 | 634 | 0.10-0.15 | 0.50-1.25 | 0.04 | 0.03 | 0.50 | 15.00-16.00 | 4.00-5.00 | – | 2.50-3.25 | – | – |

| S17600 | 635 | 0.08 | 1.00 | 0.04 | 0.03 | 1.00 | 16.00-17.50 | 6.00-7.50 | 0.4 | – | 0.40-1.20 | – |

| S15500 | XM-12 | 0.07 | 1.00 | 0.04 | 0.03 | 1.00 | 14.00-15.50 | 3.50-5.50 | – | – | – | 2.50-4.50 |

| S13800 | XM-13 | 0.05 | 0.20 | 0.01 | 0.008 | 0.10 | 12.25-13.25 | 7.50-8.50 | 0.90-1.35 | 2.00-2.50 | – | – |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00-12.50 | 7.50-9.50 | – | 0.5 | 0.90-1.40 | 1.50-2.50 |

| S45503 | – | 0.01 | 0.50 | 0.01 | 0.01 | 0.20 | 11.00-12.50 | 7.50-9.50 | – | 0.5 | 1.00-1.35 | 1.50-2.50 |

| S45000 | XM-25 | 0.05 | 1.00 | 0.03 | 0.03 | 1.00 | 14.00-16.00 | 5.00-7.00 | – | 0.50-1.00 | – | 1.25-1.75 |

Mechanical Properties

| UNS No. | Type | Condition | Aging Treatment | Tensile Strength, min (ksi) | Yield Strength, min (ksi) | Elongation in 2 in., min % | Reduction of Area, min % | Hardness (Rockwell C) |

| S17400 | 630 | H900 | 900°F (480°C) / 1h | 190 | 170 | 10 | 35 | 40 |

| S17400 | 630 | H1025 | 1025°F (550°C) / 4h | 155 | 145 | 12 | 45 | 35 |

| S17400 | 630 | H1150 | 1150°F (620°C) / 4h | 135 | 105 | 16 | 50 | 28 |

| S17700 | 631 | H1050 | 1050°F (565°C) / 4h | 170 | 150 | 10 | 40 | 35 |

| S15700 | 632 | H925 | 925°F (495°C) / 4h | 170 | 155 | 10 | 38 | 38 |

| S35500 | 634 | H1000 | 1000°F (540°C) / 4h | 180 | 160 | 8 | 30 | 37 |

| S17600 | 635 | H1050 | 1050°F (565°C) / 4h | 170 | 150 | 10 | 40 | 35 |

| S15500 | XM-12 | H900 | 900°F (480°C) / 1h | 190 | 170 | 10 | 35 | 40 |

| S13800 | XM-13 | H1025 | 1025°F (550°C) / 4h | 155 | 145 | 12 | 45 | 35 |

| S45500 | XM-16 | H1150 | 1150°F (620°C) / 4h | 135 | 105 | 16 | 50 | 28 |

| S45000 | XM-25 | H900 | 900°F (480°C) / 1h | 190 | 170 | 10 | 35 | 40 |

Technical Specifications

| Specification | Value |

| Standard | ASTM A564/A564M Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| Grade | 630 (S17400), 631 (S17700), 632 (S15700), 634 (S35500), 635 (S17600), XM-12 (S15500), XM-13 (S13800), XM-16 (S45500), and XM-25 (S45000) |

| Delivery Condition | Annealed, Solution Hardening or Aging |

| MFG. Methods | Hot-finished or cold-finished |

| Shape of Bars | Rounds, Squares, Hexagons, Bar shapes, Angles, Tees, and Channels |

| Density | 7.93 – 7.98g/cm³ |

| Dimension | Rounds Diameter Range: 1/8 inch (3.18 mm) to 12 inches (304.8 mm) Squares Side Length Range: 1/4 inch (6.35 mm) to 6 inches (152.4 mm) Hexagons Flat-to-Flat Range: 1/4 inch (6.35 mm) to 6 inches (152.4 mm) Angles Leg Length Range: 1/2 inch (12.7 mm) to 6 inches (152.4 mm) Thickness Range: 1/8 inch (3.18 mm) to 3/4 inch (19.05 mm) T-Shapes Leg Length Range: 1 inch (25.4 mm) to 3 inches (76.2 mm) Thickness Range: 1/8 inch (3.18 mm) to 1/2 inch (12.7 mm) Channels Flange Width Range: 3/4 inch (19.05 mm) to 3 inches (76.2 mm) Web Height Range: 1 inch (25.4 mm) to 4 inches (101.6 mm) Thickness Range: 1/8 inch (3.18 mm) to 3/8 inch (9.53 mm) |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Analysis, Tensile Test, Hardness Test, Visual and Dimensional Inspection, Intergranular Corrosion Test, Impact Test, Ultrasonic Testing |

Packing

Small diameter packed in plywood box; large diameter packed on plywood pallets.

Application

|

Grade |

UNS No. | Applications |

| 630 | S17400 | Aerospace components, chemical processing equipment, nuclear reactor components, pump shafts, turbine blades, valve parts |

| 631 | S17700 | Springs, fasteners, surgical instruments, and high-strength components in the aerospace and automotive industries |

| 632 | S15700 | Aerospace and industrial applications requiring high strength and moderate corrosion resistance, bolts, screws, fasteners, high-stress components |

| 634 | S35500 | High-performance applications, aerospace components, high-performance shafts, and mechanical parts require high stress and fatigue resistance |

| 635 | S17600 | Aerospace components, nuclear reactor parts, chemical processing equipment, high strength, corrosion, and oxidation resistance at elevated temperatures |

| XM-12 | S15500 | Aerospace applications, high-strength shafts, fasteners, valve parts, excellent mechanical properties, good resistance to corrosion and stress cracking |

| XM-13 | S13800 | Aerospace and medical industries, surgical instruments, high-strength fasteners, parts requiring high toughness and moderate corrosion resistance |

| XM-16 | S45500 | High-strength components in aerospace and chemical processing industries, parts maintaining high strength and toughness at elevated temperatures |

| XM-25 | S45000 | Aerospace and industrial components requiring high strength and good corrosion resistance, fasteners, shafts, high-performance mechanical parts |