ASTM B161 Seamless Nickel 200, Nickel 201 Pipe and Tube

- Type: Seamless Pipe and Tube

- Grade: UNS N02200 (Nickel 200), UNS N02201 (Nickel 201)

- Outside Diameter (OD): NPS 1/8″ -8″ 910.3-219.1mm)

- Wall Thickness (WT): SCH5, SCH10, SCH40, SCH80

Features

ASTM B161 Seamless Nickel 200, Nickel 201 Pipe and Tube

Nickel 200 & Nickel 201 Pipe & Tube Chemical Composition (wt%)

| Element | Nickel 200 / UNS N02200 | Nickel 201 / UNS N02201 |

| Nickel (Ni) min. | 99 | 99 |

| Iron (Fe) max. | 0.4 | 0.4 |

| Manganese (Mn) max. | 0.35 | 0.35 |

| Carbon (C) max. | 0.15 | 0.02 |

| Silicon (Si) max. | 0.35 | 0.35 |

| Copper (Cu) max. | 0.25 | 0.25 |

| Sulfur (S) max. | 0.01 | 0.01 |

Nickel 200 & Nickel 201 Pipe & Tube Mechanical Properties

| Property | Nickel 200 / UNS N02200 | Nickel 201 / UNS N02201 |

| Tensile Strength (min) | 550 MPa (80 ksi) | 380 MPa (55 ksi) |

| Yield Strength 0.2% Offset (min) | 105 MPa (15 ksi) | 105 MPa (15 ksi) |

| Elongation (min) | 40% | 40% |

Technical Specifications

| Specification | Value |

| Standard | ASTM B161 Nickel Seamless Pipe and Tube |

| Grade | UNS N02200 (Nickel 200), UNS N02201 (Nickel 201) |

| Manufacturing Process | cold-worked |

| Seam Type | Seamless |

| Pipe Size | Outside Diameter (OD) Range: NPS 1/8″-8″ (10.3-219.1mm), Wall Thickness (WT) Range: SCH5, SCH10, SCH40, SCH80 |

| Tube Size | Outside Diameter (OD) Range: 6.35-127mm, Wall Thickness (WT) Range: 1.27-12.7mm |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

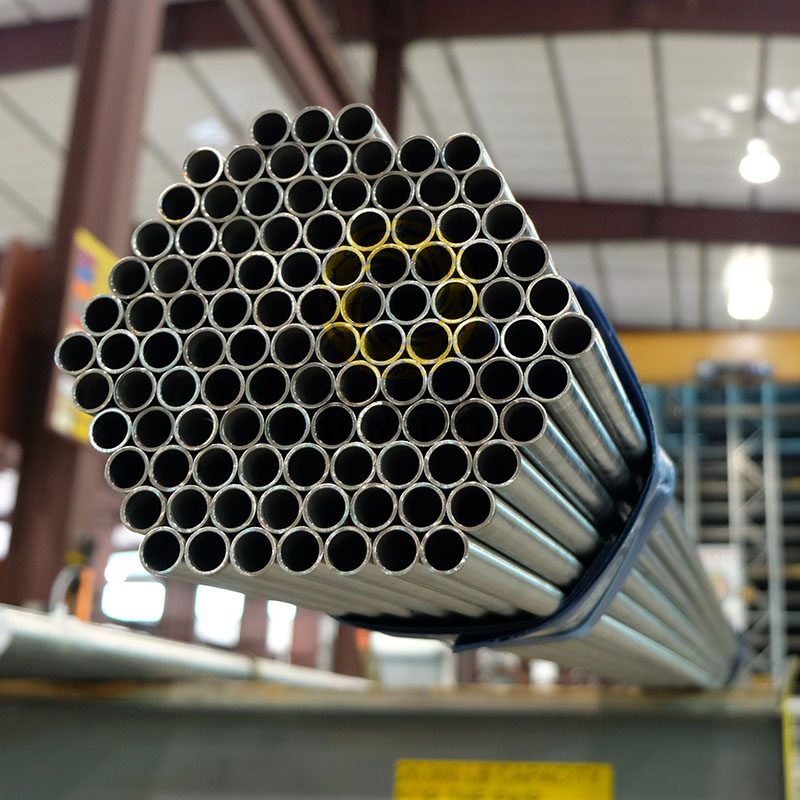

Packing

Small Diameter Pipes and Tubes:

End treatment: Beveled or plain ends are capped or plugged with plastic protectors.

Bundling: Smaller diameter pipes and tubes are grouped in bundles.

Protection: Bundles are then covered with seaworthy bags to protect against moisture and damage during transport.

Alternative packaging: For specific needs or handling requirements, small-diameter pipes can also be loosely packed in plywood boxes instead of bundled in bags.

Large Diameter Pipes:

End treatment: Similar to small diameters, beveled or plain ends are likely capped or plugged.

Loose packing: Larger diameter pipes are individually packed and not bundled due to their size and weight.

Protection: Each pipe is covered with a seaworthy bag to protect it against the elements and potential damage during shipping.

Application

Handling caustic soda (sodium hydroxide): Nickel 200 exhibits excellent resistance to caustic soda at various concentrations and temperatures, making it suitable for pipelines, reactors, and other equipment in caustic soda production and handling.

Processing of other alkaline solutions: Used for handling potassium hydroxide and other alkaline solutions.

Production of synthetic fibers: Resists corrosive chemicals used in manufacturing synthetic fibers, such as rayon and nylon.

Equipment for handling food products: Suitable for applications where hygiene and corrosion resistance are critical, such as handling salt, brine, and other food products.

Components in electronic devices: Its high electrical conductivity and corrosion resistance make it suitable for various electronic applications.

Battery components: Used in nickel-cadmium and other battery systems.

Aerospace and rocketry: Components requiring high purity and good thermal conductivity.

Laboratory equipment: Used in laboratory apparatus and instrumentation due to its corrosion resistance and inertness.

Caustic evaporators: Nickel 200 tubes are commonly used in caustic evaporators due to their excellent resistance to concentrated caustic solutions at high temperatures.

Salt production: Pipelines and equipment for handling brine and salt solutions.

Food processing equipment: Tubing for handling milk, juices, and other food products.