ASTM B165 Seamless Monel 400 Alloy Pipe and Tube

- Type: Seamless Pipe and Tube

- Grade: UNS N04400 (Monel 400)

- Outside Diameter (OD): NPS 1/8″ -8″ (10.3-219.1mm)

- Wall Thickness (WT) : SCH5, SCH10, SCH40, SCH80

Features

ASTM B165 Seamless Monel 400 Nickel-Copper Alloy Pipe and Tube

Monel 400 (UNS N04400) Seamless Pipe and Tube Chemical Composition (wt.%)

| Element | Composition Range (%) |

| Nickel (Ni) | 63.0-70.0 |

| Copper (Cu) | Remainder |

| Iron (Fe) | 2.5 max |

| Manganese (Mn) | 2.0 max |

| Carbon (C) | 0.3 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.024 max |

Mechanical properties for ASTM B165 seamless nickel-copper alloy (UNS N04400) tubes in annealed and stress-relieved conditions

| Condition | Outside Diameter (OD) | Tensile Strength (MPa) | Yield Strength (0.2% Offset) (MPa) | Elongation (%) |

| Annealed | ≤ 5″ (≤ 127 mm) | 480 (min) | 195 (min) | 35 (min) |

| Annealed | > 5″ (> 127 mm) | 480 (min) | 170 (min) | 35 (min) |

| Stress-Relieved | All sizes | 585 (min) | 380 (min) | 15 (min) |

Technical Specifications

| Specification | Value |

| Standard | ASTM B165 Nickel-Copper Alloy Seamless Pipe and Tube |

| Grade | UNS N04400, MONEL 400, EN 2.4360, NiCu30Fe |

| Manufacturing Process | Cold-worked |

| Seam Type | Seamless |

| Pipe Size | Outside Diameter (OD) Range: NPS 1/8″ -8″ (10.3-219.1mm), Wall Thickness (WT) Range: SCH5, SCH10, SCH40, SCH80 |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

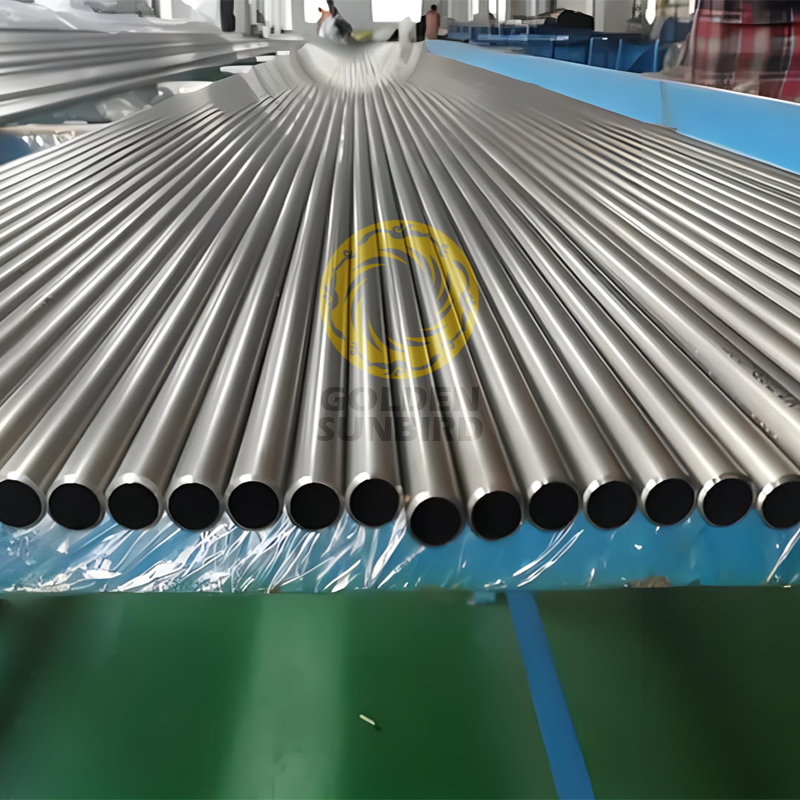

Packing

Small Diameter Pipes and Tubes:

End treatment: Beveled or plain ends are capped or plugged with plastic protectors.

Bundling: Smaller diameter pipes and tubes are grouped in bundles.

Protection: Bundles are then covered with seaworthy bags to protect against moisture and damage during transport.

Alternative packaging: For specific needs or handling requirements, small-diameter pipes can also be loosely packed in plywood boxes instead of bundled in bags.

Large Diameter Pipes:

End treatment: Similar to small diameters, beveled or plain ends are likely capped or plugged.

Loose packing: Larger diameter pipes are individually packed and not bundled due to their size and weight.

Protection: Each pipe is covered with a seaworthy bag to protect it against the elements and potential damage during shipping.

Application

ASTM B165 UNS N04400, also known as Monel 400, is a nickel-copper alloy renowned for its exceptional corrosion resistance.

Chemical Processing: Handling various corrosive chemicals in piping systems, heat exchangers, and reaction vessels.

Marine Environments: Seawater piping systems, desalination plants, offshore oil and gas exploration due to their excellent resistance to saltwater corrosion.

Pulp and Paper Mills: Handling corrosive liquors used in the pulping process.

Food Processing Equipment: This is for specific food contact applications due to its corrosion resistance and cleanability.

Hydrocarbon Processing: Piping systems for oil and gas production, especially in applications with H2S (sour gas) due to its resistance to corrosion and sulfide stress cracking.