| Specification |

Value |

| Standard |

ASTM B338 Titanium and Titanium Alloy Tube |

| Grade |

Grade 2, Grade 5, Grade 7, Grade 9, Grade 12 |

| Seam Type |

Seamless and Welded |

| O.D. |

9.53 – 88.9mm (3/8″ – 3 1/2″) |

| W.T. |

0.5 – 10mm (0.020″-0.394″) |

| Length |

3000 – 12000mm |

| Density |

4.51 g/cm3 |

| Shapes of Tube |

Straight Tubes, U-Tubes, Tube Coils |

| Inspection Certificate |

EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests |

Chemical Analysis, Tensile Test ASTM E8/E8M, Flattening Test ASTM A370, Flaring Test, NDE Test (ET/UT/EMT/HT) |

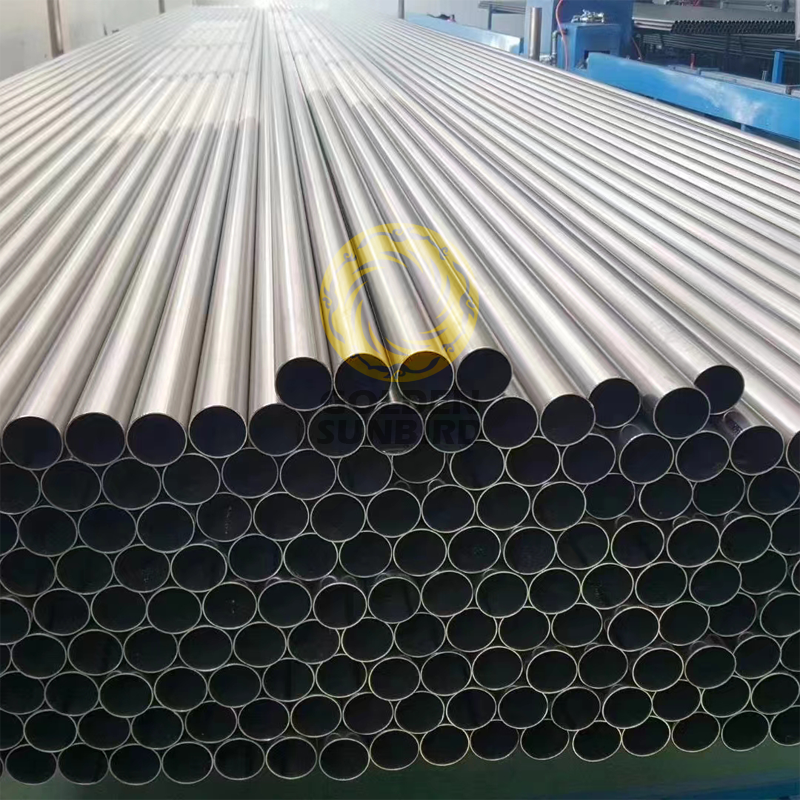

Packing

Straight or plain ends with plastic caps, bundled and covered with seaworthy bags, or packed in plywood crates.

Application

Heat exchangers: Grade 2 titanium tube resistance to corrosion from various chemicals, including chlorides and acids, makes it perfect for heat exchangers in chemical processing plants.

Pressure vessels: Titanium tubing’s high strength and corrosion resistance make them ideal for pressure vessels used in chemical processing and storage.

Piping systems: Titanium tube offers excellent resistance to pitting and crevice corrosion, making them reliable for transporting corrosive chemicals.

Marine applications: Grade 5 titanium tube’s resistance to seawater corrosion makes it suitable for marine applications like shipbuilding, desalination plants, and offshore structures.

Power generation: Due to their corrosion resistance and high strength, ASTM B338 titanium tubes are used in power plants for condenser tubing and other applications.

Sports equipment: Grade 9 titanium tube’s lightweight and high strength make it ideal for high-performance sports equipment, such as bicycle frames and golf clubs.