ASTM B387 Molybdenum and Molybdenum Alloy Bar and Wire

- Type: Bar and Wire

- Mo 360—Unalloyed VAC Mo

- Mo 361—Unalloyed P/M Mo

- Mo Alloy 363—VAC Mo-0.5Ti-0.1Zr (TZM) alloy

- Mo Alloy 364—P/M Mo-0.5Ti-0.1Zr (TZM) alloy

- Mo 365—Unalloyed VAC Mo, Low carbon

- Mo Alloy 366—VAC Mo-30W alloy

Features

ASTM B387/B387M Molybdenum and Molybdenum Alloy Bar and Wire

Molybdenum 360—Unalloyed vacuum arc-cast molybdenum.

Molybdenum 361—Unalloyed powder metallurgy molybdenum.

Molybdenum Alloy 363—Vacuum arc-cast molybdenum–0.5 % titanium–0.1 % zirconium (TZM) alloy.

Molybdenum Alloy 364—Powder metallurgy molybdenum–0.5 % titanium–0.1 % zirconium (TZM) alloy.

Molybdenum 365—Unalloyed vacuum arc-cast molybdenum, low carbon.

Molybdenum Alloy 366—Vacuum arc-cast molybdenum, 30 % tungsten alloy.

Chemical Composition (wt.%)

| Element | 360 | 361 | 363 | 364 | 365 | 366 |

| C | 0.030 max | 0.010 max | 0.010–0.030 | 0.010–0.040 | 0.010 max | 0.030 max |

| O | 0.0015 | 0.007 | 0.003 | 0.03 | 0.0015 | 0.0025 |

| N | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| Fe | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Ni | 0.002 | 0.005 | 0.002 | 0.005 | 0.002 | 0.002 |

| Si | 0.01 | 0.01 | 0.01 | 0.005 | 0.01 | 0.01 |

| Ti | – | – | 0.40–0.55 | 0.40–0.55 | – | – |

| W | – | – | – | – | – | 27–33 |

| Zr | – | – | 0.06–0.12 | 0.06–0.12 | – | – |

| Mo | Balance | Balance | Balance | Balance | Balance | Balance |

Mechanical Requirements for Round Bars and Rods

| Type | Temper | Diameter Range (in.) | Tensile Strength (min ksi) | Yield Strength 0.2% Offset (min ksi) | Elongation in 1 in. (50 mm) min % | Hardness (Vickers-10 kg) |

| 360, 361, 365 | SR | Various | 65-85 | 55-65 | 10-18 | 205-280 |

| 363, 364 | SR | 3/16 to 3 1/2 | 85-115 | 75-100 | 5-18 | 235-320 |

| 366 | SR | 3/16 to 3 1/2 | 75-95 | 60-80 | 2-5 | 225-300 |

| 360 | RX | Under 2 to 3 1/2 | 55-60 | 25-35 | 20 | 200 max |

| 363, 364 | RX | Under 2 to 3 1/2 | 75-80 | 45-55 | 10-20 | 215 max |

SR = Stress-relieved, RX = Essentially fully recrystallized.

Technical Specifications

| Specification | Value |

| Standard | ASTM B387 Molybdenum and Molybdenum Alloy Bar, Rod, and Wire |

| Grade | Molybdenum 360, Molybdenum 361, Molybdenum Alloy 363, Molybdenum Alloy 364, Molybdenum 365, Molybdenum Alloy 366 |

| Condition & Finish | Furnished in the wrought and stress-relieved condition; Black, chemical cleaned |

| Type | Bar, Rod, Wire |

| Bar and Rod | Any straight product with a round, rectangular, hexagonal, or octagonal solid cross-section, 4 in. (101.6 mm) in diameter or less, or of equivalent cross-sectional area. |

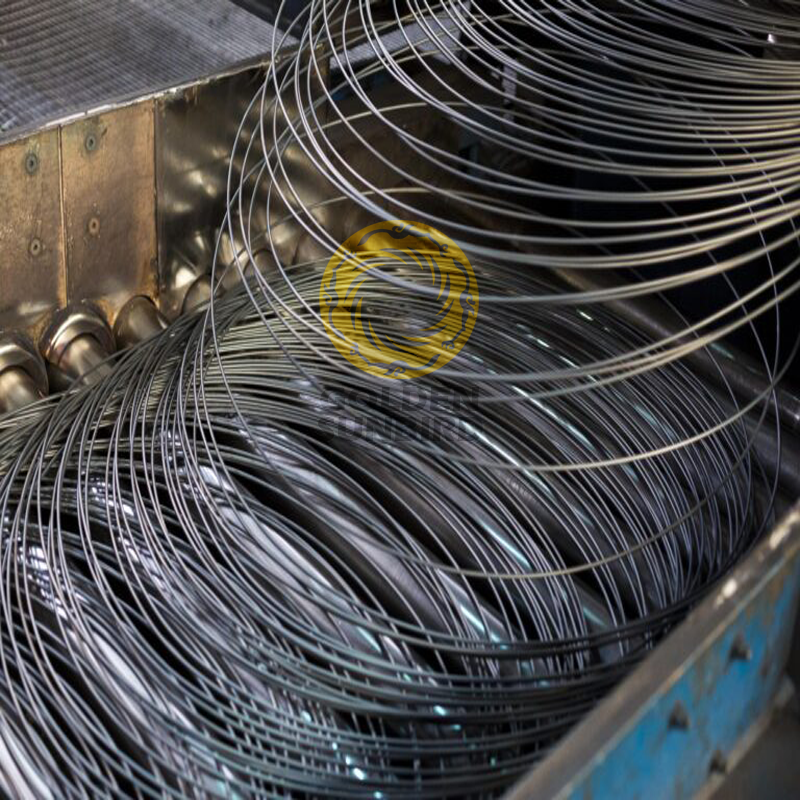

| Wire | Any product furnished in coils or on spools or reels. This specification covers wire no smaller than 0.020 in. (0.51mm) in diameter or equivalent cross-sectional area. Specification F289 covers diameters up to 0.020 in. |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Tensile Test |

Packing

Coils or Spools: Molybdenum and molybdenum alloy bars and wires are often wound onto coils or spools for easy handling and transportation.

Wooden Crates or Boxes: Bars and wires are packed in sturdy wooden crates or boxes for larger quantities or bulk shipments.

Application

Electrodes: Used as electrodes in glass melting furnaces due to their resistance to molten glass and ability to withstand high temperatures.

Stirrers and Gob Feeders: These are employed to stir the molten glass and feed it into molds for glass-forming processes.

Heating elements: Serve as heating elements in high-temperature furnaces due to their high melting point and electrical conductivity.

Structural supports: These are used for supports and fixtures within furnaces due to their high-temperature strength and creep resistance.

Mandrels and Cores: Act as mandrels and cores in metal forming processes like tube drawing and extrusion due to their high strength and wear resistance.

Medical Device Components: Employed in X-ray equipment and other medical devices requiring high-temperature resistance and biocompatibility.

Filament Supports: Due to their high melting point and low thermal expansion, filament supports are used as support wires in incandescent lamps.

Electrodes: Serve as electrodes in high-intensity discharge (HID) lamps.

Heating Elements: These are employed as heating elements in small furnaces and other electronic devices.

Grids and Supports: These are used as grids and supports in electronic tubes and vacuum devices.

Spray Wire: Utilized in thermal spray processes for coating surfaces with molybdenum for wear resistance and corrosion protection.

High-Temperature Thermocouples: Forms one leg of high-temperature thermocouples for temperature measurement in demanding environments.