ASTM B393 Niobium and Niobium Alloy Strip, Sheet, and Plate

- Type: Plate and Sheet

- R04200-Type 1—Reactor grade unalloyed Niobium,

- R04210-Type 2—Commercial grade unalloyed Niobium,

- R04251-Type 3—Reactor grade Niobium alloy containing 1 % Zirconium,

- R04261-Type 4—Commercial grade Niobium alloy containing 1 % Zirconium

- R04220-Type 5—RRR grade pure Niobium.

Features

ASTM B393 Niobium Plate and Sheet, and Niobium Alloy Strip, Plate and Sheet

R04200-Type 1—Reactor grade unalloyed niobium

R04210-Type 2—Commercial grade unalloyed niobium

R04251-Type 3—Reactor grade niobium alloy containing 1 % zirconium

R04261-Type 4—Commercial grade niobium alloy containing 1 % zirconium

R04220-Type 5—RRR grade pure niobium

Chemical Composition (wt.%)

| Element | Type 1 (R04200) | Type 2 (R04210) | Type 3 (R04251) | Type 4 (R04261) | Type 5 (RRR) |

| Carbon (C) | Max 0.01% | Max 0.01% | Max 0.01% | Max 0.01% | Max 0.003% |

| Nitrogen (N) | Max 0.01% | Max 0.01% | Max 0.01% | Max 0.01% | Max 0.003% |

| Oxygen (O) | Max 0.015% | Max 0.025% | Max 0.015% | Max 0.025% | Max 0.004% |

| Hydrogen (H) | Max 0.0015% | Max 0.0015% | Max 0.0015% | Max 0.0015% | Max 0.0005% |

| Zirconium (Zr) | – | – | 0.8 to 1.2% | 0.8 to 1.2% | – |

Mechanical properties and Brinell hardness

| Grade | Ultimate Tensile Strength (min) | Yield Strength (0.2% offset, min) | Elongation (min) | Brinell Hardness (max) |

| Types 1 & 2 | 18,000 psi (125 MPa) | 10,500 psi (73 MPa) | 20% | Type 1: 90, Type 2: 125 |

| Types 3 & 4 | 28,000 psi (195 MPa) | 18,000 psi (125 MPa) | 20% | Type 3: 125, Type 4: 135 |

| Type 5 (RRR) | 14,000 psi (95 MPa) | 7,200 psi (50 MPa) | 30% | Not specified |

Technical Specifications

| Specification | Value |

| Standard | ASTM B393 niobium plate and sheet |

| Grade | R04200-Type 1, R04210-Type 2, R04251-Type 3, R04261-Type 4, R04220-Type 5 |

| Finish | Clean, bright finish, free of defects and surface imperfections |

| Type | Plate, Sheet, Strip |

| Plate | 6 in. (152.4 mm) or more in width and greater than 3/16 in. (4.76 mm) in thickness. |

| Sheet | 6 in. (152.4 mm) or more in width and from 0.005 in. (0.13 mm) to 3/16 in. (4.76 mm) in thickness |

| Strip | may be supplied in coil, less than 6 in. (152.4 mm) in width and from 0.005 in. (0.13mm) to 3/16 in. (4.76 mm) in thickness. |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Hardness test, and Microstructural examination |

Key Features

Superconductivity: Niobium is a key material in superconductivity applications. When cooled to extremely low temperatures, it exhibits zero electrical resistance, allowing for highly efficient electricity transmission.

High Melting Point: Niobium boasts a high melting point, making it suitable for high-temperature environments.

Good Strength and Ductility: These materials possess a good balance of strength and ductility, allowing them to be formed and shaped without compromising their integrity.

Corrosion Resistance: Niobium exhibits good corrosion resistance in many environments.

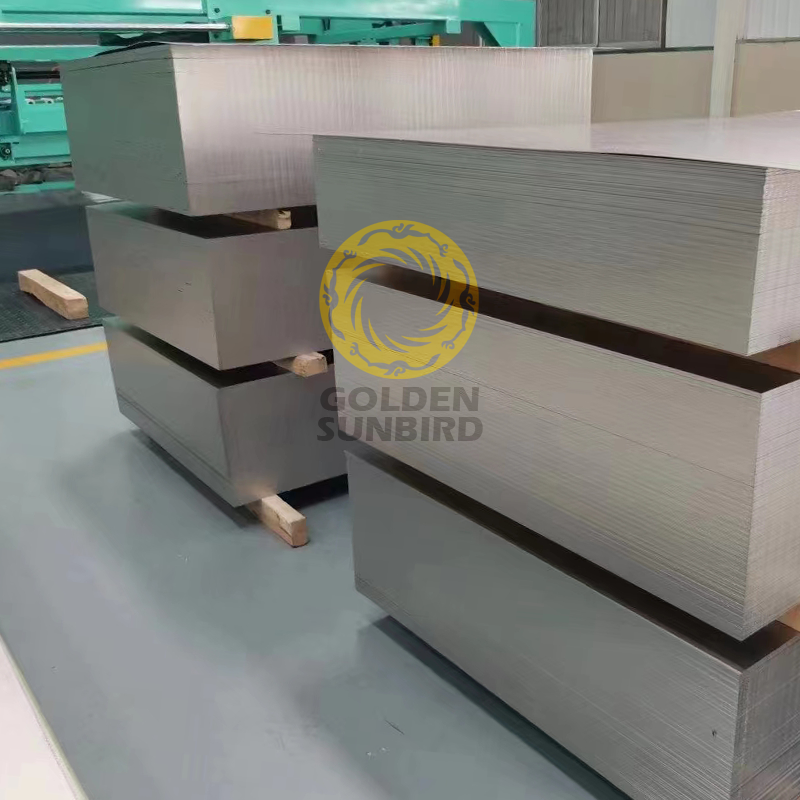

Packing

Packed on plywood boxes.

Application

UNS R04200 & R04210 (Unalloyed Niobium):

Chemical Processing: Their excellent corrosion resistance, particularly against acids, makes them ideal for chemical processing equipment like reactors, heat exchangers, and piping.

Aerospace: High-temperature strength and oxidation resistance make them suitable for rocket components, jet engine parts, and heat shields.

Medical: Biocompatibility and corrosion resistance make them valuable for medical implants and prosthetics.

Superconducting Applications: Their superconductivity at cryogenic temperatures makes them useful in superconducting magnets for MRI machines, particle accelerators, and fusion research.

UNS R04251 (Niobium-Zirconium Alloy):

Aerospace: Combines strength with good formability, making it suitable for aerospace structures.

Nuclear Industry: Resistant to radiation damage, making it suitable for nuclear reactors.

UNS R04261 (Niobium-Hafnium-Titanium Alloy):

Superconducting Applications: Offers superior performance at high frequencies, making it ideal for superconducting radio-frequency cavities.

Nuclear Industry: Resistant to radiation damage, making it suitable for nuclear reactors.

UNS R04220 (Niobium-Molybdenum Alloy):

It offers increased strength and creep resistance compared to unalloyed niobium, making it suitable for high-stress applications.