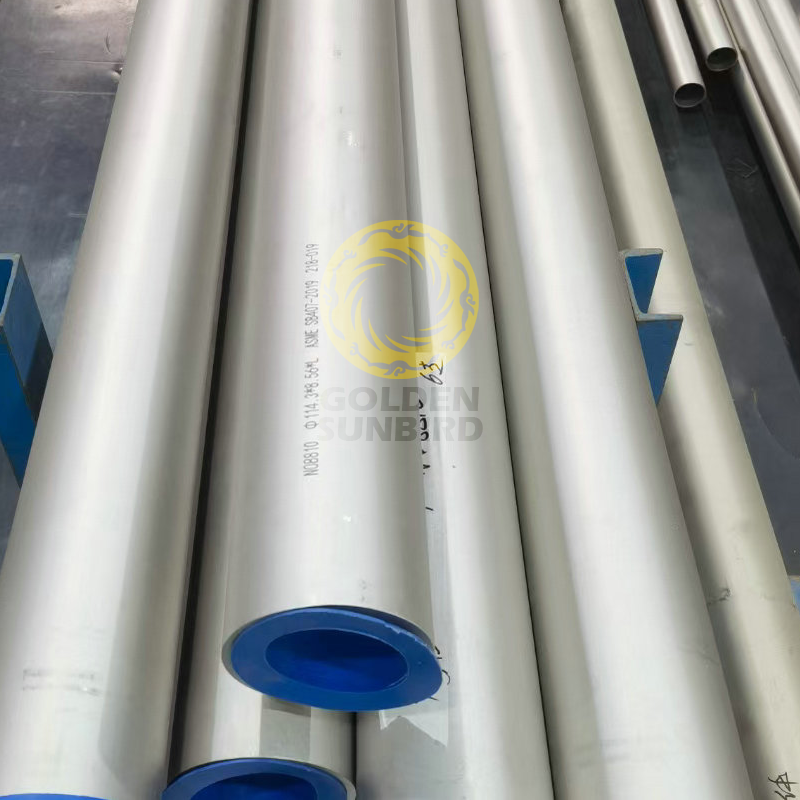

ASTM B407 Seamless Incoloy 800H/800HT Alloy Pipe and Tube

- Type: Seamless Pipe and Tube

- Grade: UNS N08120, UNS N08800 (Incoloy 800), UNS N08801, UNS N08810 (Incoloy 800H), UNS N08811 (Incoloy 800HT), UNS N08890, and UNS N06811

- Pipe SizeOutside Diameter (OD): NPS 1/4″ -6″, Wall Thickness (WT): SCH5, SCH10, SCH40, SCH80

- Tube SizeOutside Diameter (OD): 13.72 -168.3mm, Wall Thickness (WT): 1.65-8.56mm

Features

ASTM B407 Seamless Incoloy 800/800H/800HT Nickel-Iron-Chromium Alloy Pipe and Tube

Chemical composition (wt.%) for Incoloy 800/800H/800HT Seamless Pipe and Tube

| UNS No. | (Ni) | (Fe) | (Cr) | (Mn) | (C) | (Si) | (Cu) | (S) | (Al) | (Ti) |

| N08120 | 32.5-37.0 | Bal | 19.0-23.0 | 1.0 max | 0.05 max | 0.50 max | 3.0 max | 0.015 max | – | – |

| N08800 | 30.0-35.0 | 39.5 min | 19.0-23.0 | 1.5 max | 0.10 max | 1.0 max | – | 0.015 max | – | – |

| N08801 | 30.0-35.0 | 39.5 min | 21.0-25.0 | 1.5 max | 0.10 max | 1.0 max | 0.75-1.25 | 0.015 max | – | – |

| N08810 | 30.0-35.0 | 39.5 min | 19.0-23.0 | 1.5 max | 0.10 max | 1.0 max | 0.15-0.60 | 0.015 max | – | – |

| N08811 | 30.0-35.0 | 39.5 min | 19.0-23.0 | 1.5 max | 0.10 max | 1.0 max | 0.75-1.25 | 0.015 max | – | – |

| N08890 | 43.0 min | Bal | 21.0-23.5 | 1.0 max | 0.05 max | 0.10-0.50 | – | 0.015 max | 2.5-3.5 | 2.0-3.0 |

| N06811 | 43.0 min | Bal | 21.0-23.5 | 1.0 max | 0.05 max | 0.10-0.50 | – | 0.015 max | 2.5-3.5 | 2.0-3.0 |

Mechanical Properties

| Alloy | Tensile Strength (MPa) | Yield Strength (0.2% Offset) (MPa) | Elongation (%) |

| UNS N08120 | 760 min | 350 min | 30 min |

| UNS N08800 | 520 min | 210 min | 30 min |

| UNS N08801 | 590 min | 240 min | 30 min |

| UNS N08810 | 485 min | 170 min | 35 min |

| UNS N08811 | 550 min | 240 min | 30 min |

| UNS N08890 | 485 min | 170 min | 35 min |

| UNS N06811 | 550 min | 240 min | 30 min |

Technical Specifications

| Specification | Value |

| Standard | ASTM B407 Nickel-Chromium-Molybdenum-Niobium Alloys and Nickel-Chromium-Molybdenum-Silicon Alloy Pipe and Tube |

| Grade | UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and UNS N06811 |

| Manufacturing Process | cold-worked and hot-finished |

| Seam Type | Seamless |

| Pipe Size | Outside Diameter (OD) Range: NPS 1/4″ -6″, Wall Thickness (WT) Range: SCH5, SCH10, SCH40, SCH80 |

| Tube Size | Outside Diameter (OD) Range: 13.72 -168.3mm, Wall Thickness (WT) Range: 1.65-8.56mm |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

Packing

Small Diameter Pipes and Tubes:

End treatment: Beveled or plain ends are capped or plugged with plastic protectors.

Bundling: Smaller diameter pipes and tubes are grouped in bundles.

Protection: Bundles are then covered with seaworthy bags to protect against moisture and damage during transport.

Alternative packaging: For specific needs or handling requirements, small-diameter pipes can also be loosely packed in plywood boxes instead of bundled in bags.

Large Diameter Pipes:

End treatment: Similar to small diameters, beveled or plain ends are likely capped or plugged.

Loose packing: Larger diameter pipes are individually packed and not bundled due to their size and weight.

Protection: Each pipe is covered with a seaworthy bag to protect it against the elements and potential damage during shipping.

Application

Incoloy 800 (UNS N08800):

General-purpose alloy: Used in a wide range of applications across different industries.

Chemical processing: Heat exchangers, reaction vessels, and piping systems handling corrosive chemicals.

Petrochemical industry: Ethylene cracking furnaces, reformer furnaces, and other high-temperature equipment.

Food processing equipment: Components exposed to high temperatures and corrosive food products.

Incoloy 800H (UNS N08810):

Enhanced creep-rupture strength: Designed for applications requiring superior creep resistance at high temperatures.

Power generation: Superheater and reheater tubing in power plants, boiler components.

Petrochemical industry: Ethylene cracking furnaces and other high-temperature applications.

Incoloy 800HT (UNS N08811):

Highest creep and rupture strength: Suitable for the most demanding high-temperature applications.

Petrochemical industry: Ethylene cracking furnaces, reformer tubes, and other high-temperature equipment.

Industrial heating equipment: Components in furnaces and heating elements.