| Specification |

Value |

| Standard |

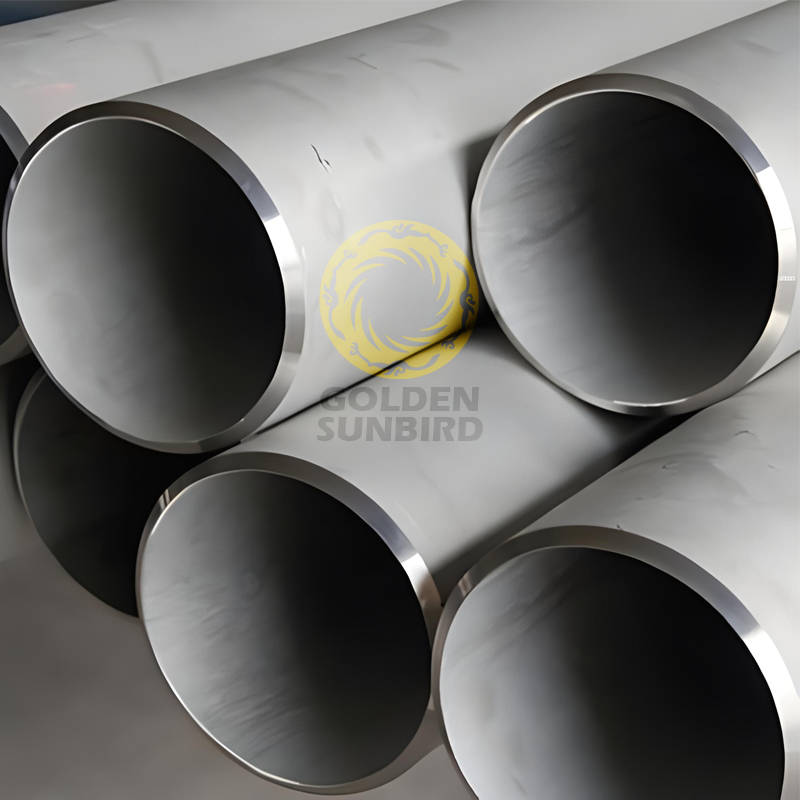

ASTM B464/B464M Welded UNS N08020 Alloy Pipe |

| Grade |

UNS N08020 (W.Nr. 2.4660, 20Cb-3, Carpenter 20, Incoloy 20) |

| Manufacturing Process |

Automatic welding |

| Seam Type |

Welded |

| Tube Size |

Outside Diameter (OD) Range: NPS 2″-8″ (60.3-168.3mm), Wall Thickness (WT) Range: SCH5S, 10S, 40S, 80S (1.65-8.18mm) |

| Length |

6000-12000mm |

| Delivery Condition |

Annealed |

| Inspection Certificate |

EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test |

Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

Packing

Bevelled / Plain Ends with Plastic Caps, Bundled or Loosely Packed.

Application

Acid Production and Handling: Due to its exceptional resistance to sulfuric acid, Alloy 20 is extensively used in the manufacture and handling of sulfuric acid, as well as phosphoric acid and nitric acid.

Chemical Reactors and Piping: Alloy 20 pipes are used in reactors, tanks, and piping systems that handle mixed acids and other corrosive media, minimizing the risk of corrosion and extending the service life of the equipment.

Heat Exchangers: The alloy’s resistance to heat and corrosion makes it suitable for heat exchangers in chemical processing plants, especially where aggressive chemicals are involved.

Synthetic Fiber Production: The corrosion-resistant properties of Alloy 20 make it ideal for pipes used in the production of synthetic fibers, where chemicals that could potentially corrode less resistant materials are used.

Pharmaceutical Plant Equipment: Alloy 20 pipes are utilized in equipment and piping systems that manufacture pharmaceuticals, offering resistance to corrosive substances and ensuring purity in the manufacturing process.

Processing Equipment: The non-reactive nature of Alloy 20 makes it suitable for food and beverage processing equipment, where maintaining the purity of products is crucial.

Storage and Handling: Alloy 20 welded pipes can be used in storage tanks and handling systems for food and beverage products, especially those involving acidic substances.

Scrubbers and Ducting: Alloy 20’s resistance to corrosion and temperature variations makes it a good choice for flue-gas scrubbers and ducting in pollution control equipment, protecting against acidic and corrosive gases.

Cooling Systems: In power plants, Alloy 20 pipes are used in cooling systems and components exposed to corrosive environments, ensuring durability and reliability.