| Specification |

Value |

| Standard |

ASTM B534 CuCoBe & CuNiBe Alloy Plate & Sheet |

| Grade |

UNS Nos. C17500 and C17510 |

| Type |

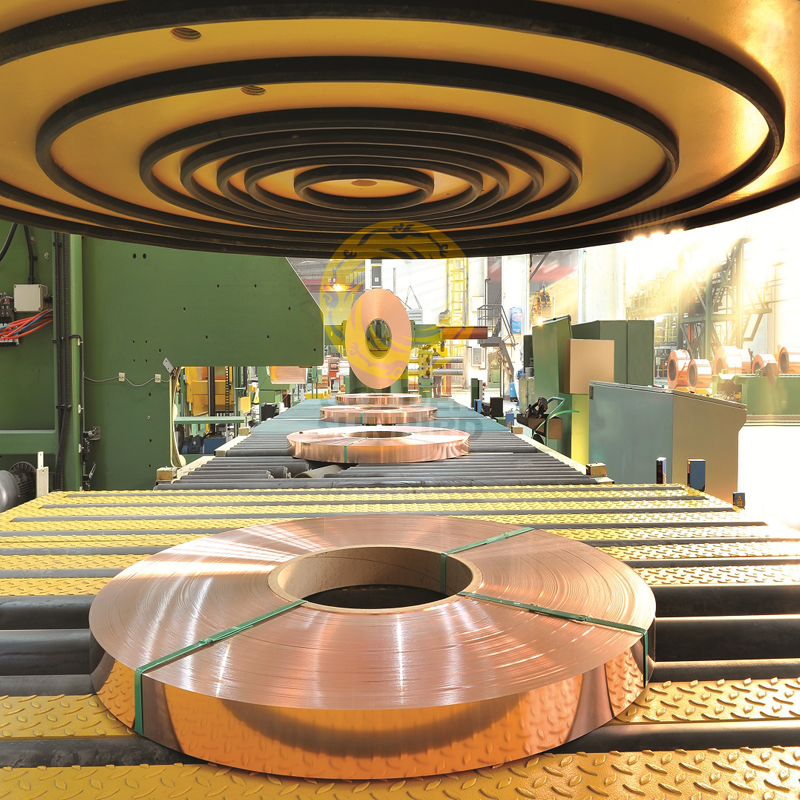

Plate, Sheet, Strip |

| Thickness |

1-50mm |

| Length |

1000 – 12000mm |

| Width |

50 – 2500mm |

| Inspection Certificate |

EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests |

Chemical Analysis, Tensile Test, UT/ET |

Packing

Packed in plywood boxes or on pallets.

Application

Connectors and Contact Springs: Materials conforming to ASTM B534 are often used in the manufacture of connectors and contact springs due to their excellent electrical conductivity and resistance to stress relaxation at elevated temperatures.

Switch Parts: The high strength and conductivity make these alloys suitable for switch parts where reliable performance under thermal stress is required.

Automotive Sensors and Actuators: The alloys’ resistance to corrosion and wear, combined with good electrical properties, make them ideal for sensors and actuators in automotive applications.

Transmission Components: Some components within the transmission system can benefit from the materials’ strength and conductivity, especially in applications demanding durability and efficient heat dissipation.

Aerospace Fasteners: The combination of high strength and moderate to high hardness makes these alloys suitable for fasteners and other components in aerospace applications, where they can contribute to weight reduction without sacrificing performance.

Electrical Connectors: In aerospace electronics, reliable and durable electrical connections are critical. ASTM B534 materials can provide the necessary conductivity and mechanical strength.

Bushings and Bearings: For applications requiring wear resistance in addition to high strength and conductivity, such as in bushings and bearings, materials according to ASTM B534 can be an excellent choice.

Tooling and Mold Making: The hardness and strength characteristics are also beneficial in tooling and mold making, particularly for components requiring durability and resistance to deformation under load.

Precision Instruments: In instruments where precise performance is crucial, and materials must not deform under stress, the specified alloys offer an attractive blend of properties.

Telecommunications Equipment: Given the requirement for reliable performance over time in a range of environmental conditions, these materials can be used in components for telecommunications infrastructure.