ASTM B550 Zirconium and Zirconium Alloy Bar and Wire

- Type: Bars and Wire

- Grade R60702—Unalloyed zirconium

- Grade R60704—Zirconium-tin alloy

- Grade R60705—Zirconium-niobium

Features

ASTM B550/B550M Zirconium and Zirconium Alloy Bar and Wire

- Grade R60702—Unalloyed zirconium.

- Grade R60704—Zirconium-tin alloy.

- grade R60705—zirconium-niobium.

Chemical Composition (wt.%)

| Element | Grades R60702 | Grades R60704 | Grades R60705 |

| Zirconium + Hafnium (min) | 99.2 | 97.5 | 95.5 |

| Hafnium (max) | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 (max) | 0.2 to 0.4 | 0.2 (max) |

| Tin | – | 1.0 to 2.0 | – |

| Hydrogen (max) | 0.005 | 0.005 | 0.005 |

| Nitrogen (max) | 0.025 | 0.025 | 0.025 |

| Carbon (max) | 0.05 | 0.05 | 0.05 |

| Niobium | – | – | 2.0 to 3.0 |

| Oxygen (max) | 0.16 | 0.18 | 0.18 |

Mechanical Properties

| Property | Grades R60702 | Grades R60704 | Grades R60705 |

| Tensile Strength (min, ksi) | 55 [380] | 60 [415] | 80 [550] |

| Yield Strength (min, ksi) | 30 [205] | 35 [240] | 55 [380] |

| Elongation (min, %) | 16 | 14 | 16 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B550/B550M Zirconium and Zirconium Alloy Bar and Wire |

| Grade | Grade R60702—Unalloyed zirconium (Zr702), Grade R60704—Zirconium-tin alloy (Zr704), Grade R60705—zirconium-niobium (Zr705) |

| Condition & Finish | Annealed, cold worked, and stress relieved; clean, smooth surface finish |

| Type | Bars and Wires |

| Size | Bars: (Condition: hot finished, hot finished and annealed, cold finished, cold finished and annealed) Hot-finished round, squares, octagons, and hexagons Diameter or Size:≥6.4mm Hot-finished flats Size: Width 6.4-254mm x Thickness≥3.2mm Cold-finished rounds, squares, octagons, hexagons, and shapes Diameter or Size:≥13mm Cold-finished flats Size: Width≥9.5mm x Thickness≥3.2mm Wire: (Condition: cold finished, cold finished and annealed) Cold-finished rounds, squares, octagons, hexagons, and shapes Diameter or Size:≤13mm Cold-finished flats Size: Width: 1.6-9.5mm x Thickness: 0.25-4.8mm |

| Length | Upon the customer’s request |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical analysis, Tensile test, Hardness test, and Non-destructive test (UT) |

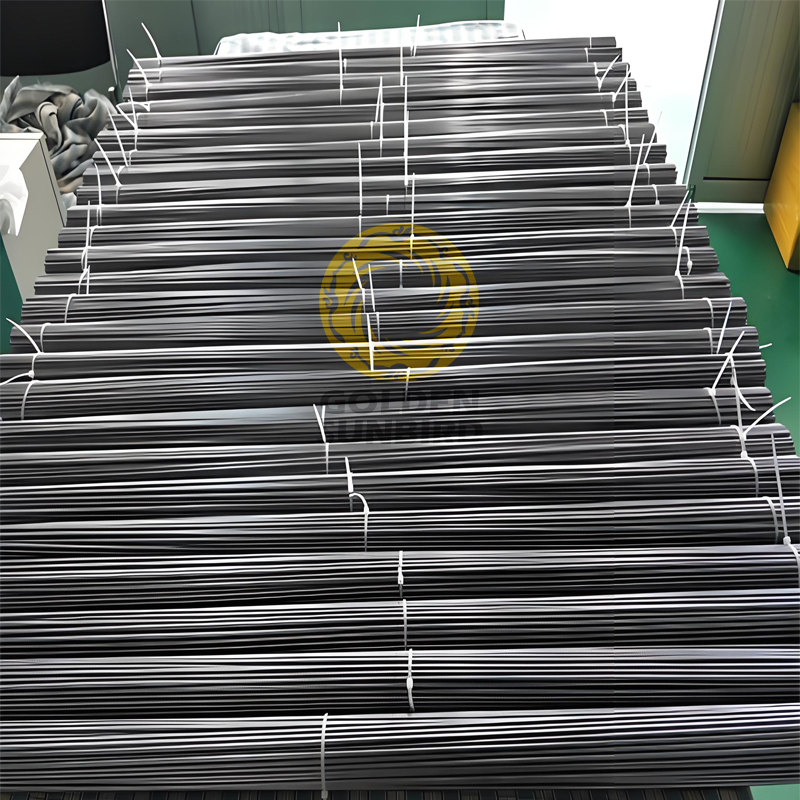

Packing

Packed in plywood boxes.

Applications

Chemical Processing Industry: Zirconium alloys are corrosion-resistant by most organic and inorganic acids, alkalis, and salt solutions. This makes them ideal for constructing acid production equipment and handling other corrosive chemicals. Applications include pumps, valves, heat exchangers, and reactors where materials must withstand harsh, corrosive environments.

Nuclear Industry: Zirconium is primarily used in nuclear reactors due to its low neutron absorption characteristics. It is commonly used for cladding nuclear fuel rods, which helps prevent the rods’ corrosion during reactor operation and does not interfere with nuclear reactions.

Aerospace Sector: Zirconium alloys’ strength and corrosion resistance make them suitable for various aerospace applications, including components in jet engines and airframes that require materials capable of withstanding high temperatures and corrosive environments.

Medical Applications: Due to its biocompatibility, zirconium is used in medical devices, such as surgical instruments, dental implants, and hip replacements. Its good wear resistance and lack of reactivity with bodily fluids or tissues make it an excellent material for long-term implantation in the human body.

Automotive Industry: Due to their excellent heat resistance, zirconium alloys can be used in sensors and high-performance engine components. They are also used in exhaust systems and other parts where resistance to corrosion increases longevity and performance.

Electronics: Zirconium is used in electronic applications for its excellent electrical conductivity. Zirconium alloy bars and wires are used in computer applications and the construction of mobile phones, particularly in heat dissipation components.

Jewellery and Decorative Applications: Zirconium is sometimes used in jewellery making due to its strong resistance to corrosion and aesthetic appearance. It is often used as a substitute for titanium in rings and bracelets.