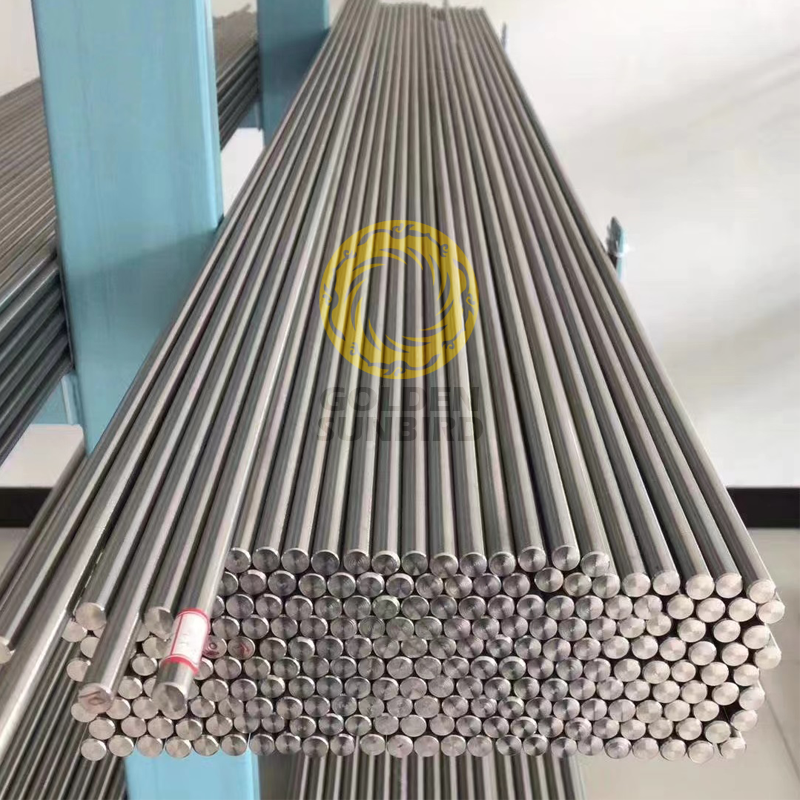

ASTM F1813 Ti12Mo6Zr2Fe Titanium Alloy Bar for Surgical Implant

- Grade: Ti-12Mo-6Zr-2Fe

- Round Bar Dia:4.76-101.6mm

- Round Wire Dia:≤4.76mm

- High Strength

- Biocompatibility

- Corrosion Resistance

- Improved Wear Resistance

Features

ASTM F1813 Wrought Ti12Mo6Zr2Fe (UNS R58120) Titanium alloy bar used for surgical implant

Chemical Composition (wt.%)

| Element | Min | Max |

|---|---|---|

| Molybdenum | 10.0 | 13.0 |

| Zirconium | 5.0 | 7.0 |

| Iron | 1.5 | 2.5 |

| Oxygen | – | 0.28 |

| Nitrogen | – | 0.05 |

| Carbon | – | 0.05 |

| Hydrogen | – | 0.020 |

| Titanium | Balance | – |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (min) | 135,000 psi (931.5 MPa) |

| Yield Strength (0.2% Offset, min) | 130,000 psi (897 MPa) |

| Elongation in 2 in. or 4D (min) | 12% |

| Reduction of Area (min) | 30% |

Technical Specifications

| Specification | Value |

| Standard | ASTM F1813 Wrought Titanium – 12 Molybdenum – 6 Zirconium – 2 Iron Alloy for Surgical Implant (UNS R58120) |

| Grade | Ti12Mo6Zr2Fe, β-Ti12Mo6Zr2Fe |

| Condition & Finish | Descaled or pickled, sandblasted, chemically milled, ground, machined, peeled, polished; Annealed or as rolled |

| Type | Bar, Wire |

| Dimension | Bar—Rounds or flats from 3⁄16 in. (4.76 mm) to 4 in.(101.60 mm) in diameter or thickness (other sizes and shapes by special order). |

| Wire—Rounds or flats less than 3⁄16 in. (4.76 mm) in diameter or thickness. | |

| Density | 4.51g/cm³ |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Composition, Mechanical Properties |

Key Properties

High Strength: This alloy offers a high strength-to-weight ratio, which is crucial for implants that need to withstand mechanical stresses without adding excessive weight to the patient’s body.

Biocompatibility: Like other titanium alloys, Ti12Mo6Zr2Fe is highly biocompatible, meaning it is not harmful or toxic to living tissue. This reduces the risk of rejection and complications post-surgery.

Corrosion Resistance: The alloy’s excellent corrosion resistance ensures the longevity and stability of implants in the harsh environment of the human body.

Improved Wear Resistance: The specific composition of this alloy, including molybdenum, zirconium, and iron, enhances its wear resistance compared to pure titanium. This is particularly important for joint replacements and other implants subject to repetitive motion.

Packing

Wire wounded on reel or spool, bars, and rods packed in plywood boxes or on pallets.

Applications in Surgical Implants

Joint Replacements: The alloy’s strength and wear resistance make it suitable for hip and knee replacements, where the implant must endure repeated loads and motion.

Dental Implants: Its biocompatibility and strength are ideal for dental implants that replace tooth roots and must bond well with bone.

Bone Fixation Devices: Ti12Mo6Zr2Fe can be used in plates, screws, and other devices for bone fixation, supporting bone healing while minimizing the risk of infection or rejection.

Spinal Implants: The alloy’s mechanical properties and biocompatibility suit spinal fusion surgeries, where implants must support the vertebrae while facilitating bone growth.

Cardiovascular Devices: Its corrosion resistance and biocompatibility make it a candidate for pacemaker cases and other cardiovascular implants.