|

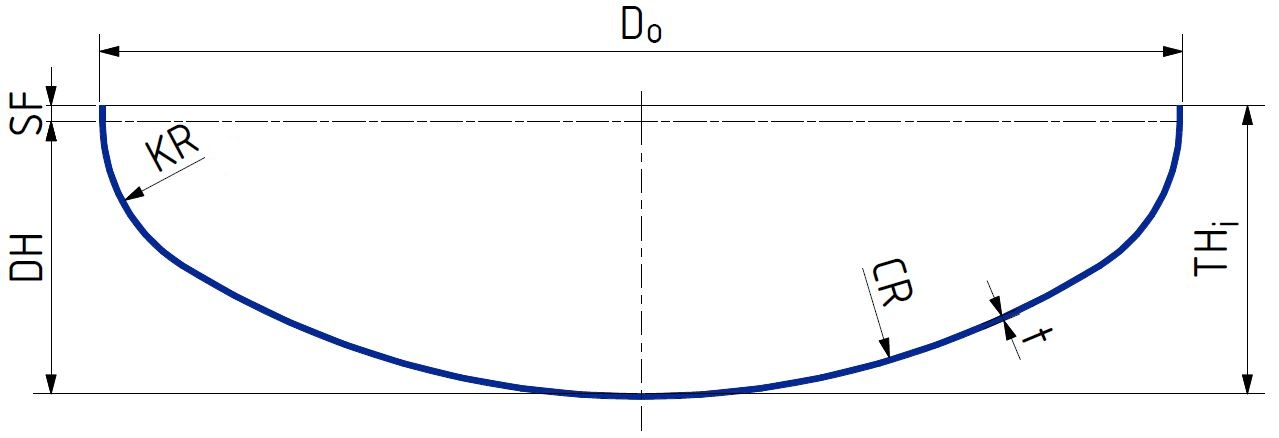

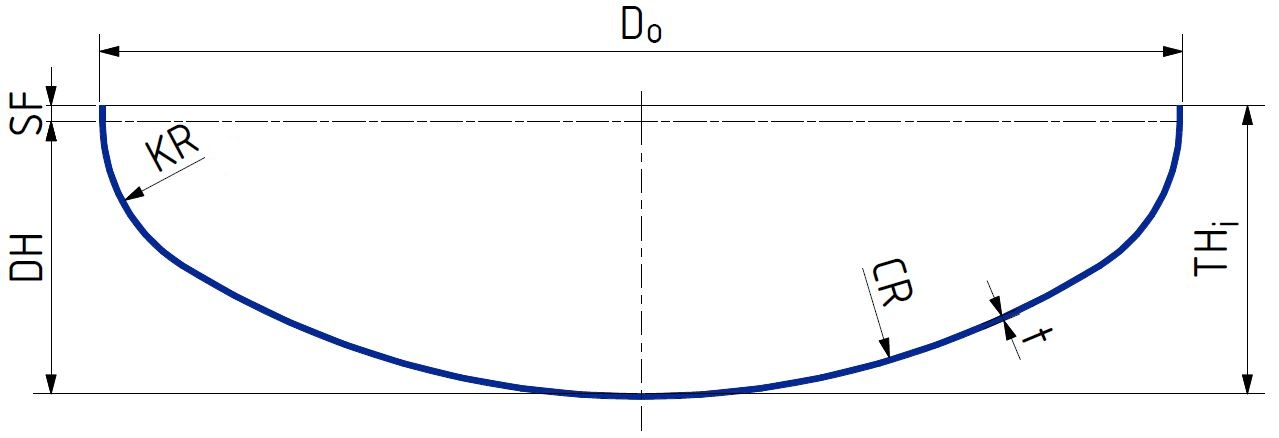

CR = 0.8Do |

| KR = 0.154Do |

| SF = 3t or per request |

| DH = 0.255Do – 0.635t |

| THi = SF+DH |

| D0 = external head diameter |

| Di = internal head diameter |

| CR = crown radius |

| KR = knuckle radius |

| SF = straight flange height |

| DH = depth of dishing |

| THi = total internal head height |

| t = wall thickness |

| Specification |

Value |

| Standard |

DIN 28013 (1.9:1), (2:1) Titanium and Titanium Alloy Elliptical/Ellipsoidal Head |

| Grade |

ASTM B265 Grades 1, 2, 5, 7, 9, 23 |

| Type |

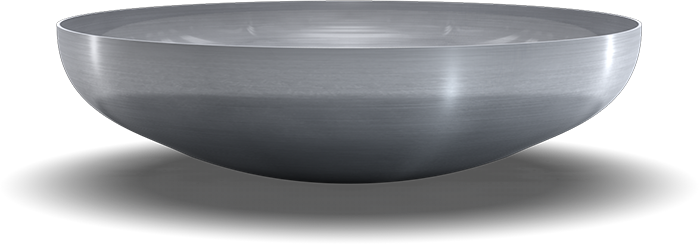

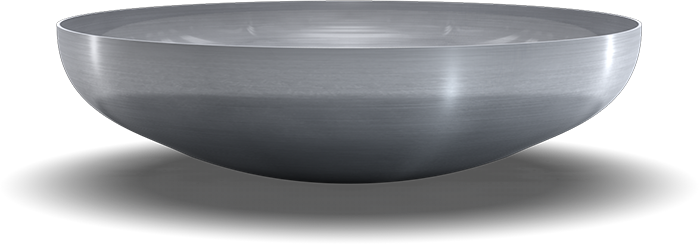

Elliptical/Ellipsoidal Head |

| Outside Diameter |

500-5250mm |

| Thickness |

3-40mm |

| Density |

4.51 g/cm3 |

| Inspection Certificate |

EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests |

Chemical Analysis, Tensile Test, UT/ET |

Packing

Packed on plywood pallets.

Application

DIN 28013 Ellipsoidal Heads, also known as 2:1 ellipsoidal heads due to their shape (the ratio of the head’s diameter to its height is approximately (2:1), are widely used in various industrial sectors.

Chemical Industry: In the chemical industry, ellipsoidal heads are commonly used in reactors, storage tanks, and pressure vessels where a high degree of resistance against internal pressure is required. The smooth, rounded shape of ellipsoidal heads helps in evenly distributing stress and reducing the concentration of stress at any single point.

Oil and Gas Industry: These heads are integral components of separators, storage tanks, and other pressurized vessels used in the oil and gas sector. Their shape helps to withstand internal pressures and the stresses associated with the storage and processing of fluids at high pressures.

Pharmaceuticals: In pharmaceutical manufacturing, ellipsoidal heads are used for pressure vessels that must maintain the integrity of sterile conditions. The contour of the head facilitates easy cleaning and sterilization, reducing contamination risks.

Food and Beverage Industry: Similar to pharmaceutical applications, the food and beverage industry uses these heads in pressure vessels for their cleanability and ability to handle internal pressure without compromising the vessel’s integrity, which is crucial for safety and quality control.

Power Generation: Ellipsoidal heads are used in boilers, steam drums, and other high-pressure vessels in power plants. Their ability to endure high pressures and temperatures makes them suitable for these applications.