Ir-Sn-Ti Anode

- High Corrosion Resistance

- Electrocatalytic Activity

- Tunable Properties

- Stability

- Durability

Product Superiority

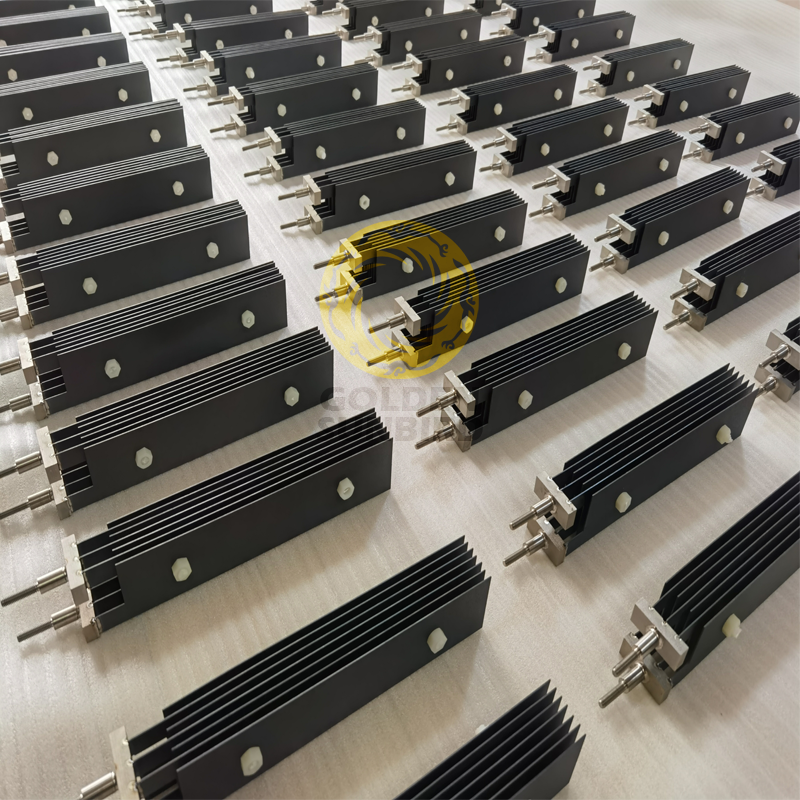

Ir-Sn-Ti anode

Ir-Sn-Ti anode, composed of iridium oxide (IrO2), tin oxide (SnO2), and a titanium (Ti) substrate, represents a relatively new and intriguing area of research in the realm of electrochemistry. While still under development and investigation, these anodes exhibit promising characteristics and potential applications. Let’s delve into what we know so far:

Properties and Advantages

High Corrosion Resistance: Similar to Ru-Ti anodes, the presence of titanium oxide provides excellent resistance to corrosion, even in harsh environments with aggressive electrolytes or high current densities.

Electrocatalytic Activity: Iridium oxide, like ruthenium oxide, exhibits strong electrocatalytic properties, particularly for oxygen evolution reactions. Tin oxide can further enhance the catalytic activity and selectivity for certain reactions.

Tunable Properties: The ratio of IrO2, SnO2, and TiO2 can be adjusted to tailor the anode’s performance for specific applications. This allows for optimizing factors like oxygen evolution overpotential, chlorine evolution selectivity, or organic compound oxidation efficiency.

Stability: Ir-Sn-Ti anodes demonstrate good stability over a wide potential range, ensuring consistent performance and preventing unwanted side reactions.

Durability: These anodes are mechanically robust and can withstand wear and tear in demanding applications.

Application Areas

Applications

The specific applications of Ir-Sn-Ti anodes are still under exploration, but some potential areas include:

Oxygen Evolution Reaction (OER): IrO2 is known for its good OER activity, making these anodes potentially suitable for water electrolysis, metal electrowinning, and other processes involving oxygen evolution.

Chlorine Evolution Reaction (CER): Depending on the composition and preparation methods, Ir-Sn-Ti anodes might exhibit activity for chlorine evolution, making them relevant for chlor-alkali processes.

Water electrolysis: Particularly for oxygen evolution in acidic or neutral environments.

Electrochlorination: Efficient production of hypochlorite for water disinfection or bleaching purposes.

Organic electrosynthesis: Selective oxidation of organic compounds for chemical production.

Electrochemical sensors: Detection and quantification of various analytes, especially when high selectivity is required.

Wastewater treatment: Oxidation of specific organic pollutants or disinfection processes.