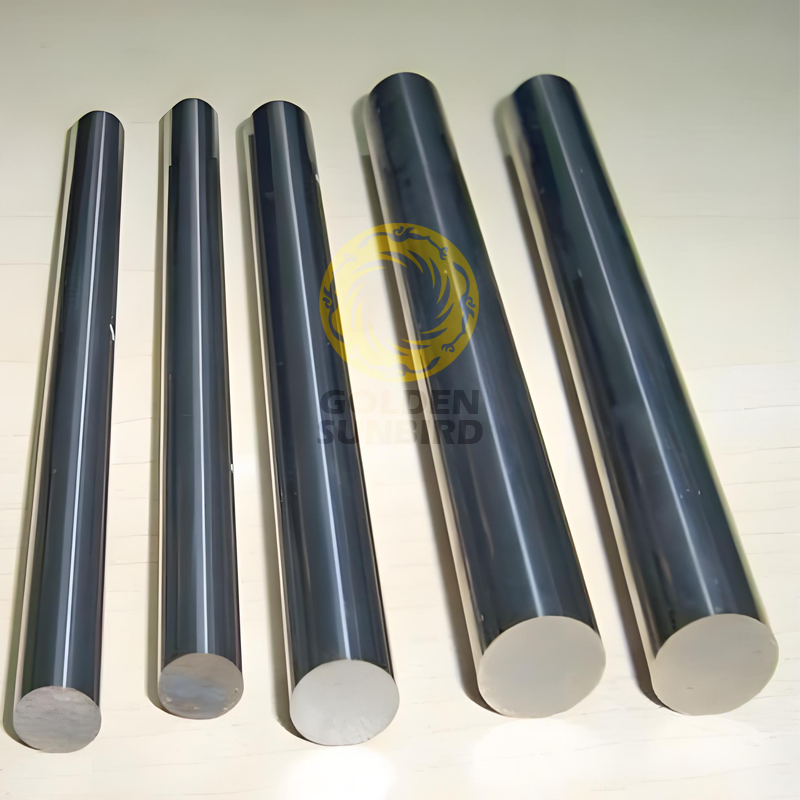

Nb521 Nb5W2Mo1Zr Niobium-Tungsten Alloy Bar, Wire, and Plate

- Type: Bar, Wire, Foil, Sheet, Strip, and Plate

- Niobium-Tungsten Alloy

- Grade: Nb521, Nb5W2Mo1Zr

Features

Nb521 Nb5W2Mo1Zr Niobium-Tungsten Alloy Bar, Wire, and Plate

Nb521 Alloy Bar Chemical Composition (wt.%)

| Element | Weight Percent (wt.%) |

| W (Tungsten) | 5.14 |

| Mo (Molybdenum) | 1.87 |

| Zr (Zirconium) | 1.33 |

| C (Carbon) | 0.0095 |

| N (Nitrogen) | 0.006 |

| O (Oxygen) | 0.01 |

| Cu (Copper) | 0.001 |

| Ti (Titanium) | 0.016 |

| Fe (Iron) | 0.001 |

| Si (Silicon) | 0.0028 |

| Ta (Tantalum) | 0.59 |

| Nb (Niobium) | Balance |

Mechanical Properties of Nb521 Alloy Sheet and Bar

| Property (Sheet) | Value (MPa or % or GPa) | Property (Bar) | Value (MPa or % or GPa) |

| Tensile Strength | 440 MPa | Tensile Strength | 470 MPa |

| Yield Strength (0.2% offset) | 328 MPa | Yield Strength (0.2% offset) | 340 MPa |

| Elongation | 31% | Elongation | 36% |

| Reduction of Area | 77% | Reduction of Area | – |

| Modulus of Elasticity (E) | 124 GPa | Modulus of Elasticity (E) | – |

| – | – | Angle of Twist (θ) | 180° |

High-Temperature Mechanical Properties of Nb521 Alloy Sheet and Bar

| Temperature (°C) | Sheet Tensile Strength [MPa] | Bar Tensile Strength [MPa] | Sheet Yield Strength (0.2% offset) [MPa] | Bar Yield Strength (0.2% offset) [MPa] |

| 1450 | 157 | 134 | 130 | 128 |

| 1500 | 135 | 113 | 119 | 108 |

| 1550 | 110 | 109 | 110 | 104 |

| 1600 | 100 | 93 | 85 | 81 |

| 1700 | 83 | 80 | 75 | 74 |

| 1800 | 63 | 65 | 60 | 59 |

| Properties | Value |

| Melting Point | 2630℃ |

| Density | 8.65 – 9.00 g/cm3 |

Technical Specifications

| Specification | Value |

| Standard | Nb521 Nb5W2Mo1Zr Niobium-Tungsten Alloy Bar Wire Plate |

| Grade | Nb521, Nb5W2Mo1Zr |

| Type | Bar, Wire, Foil, Plate, Sheet, Strip |

| Dimension | Round Bar & Wire Diameter: 1 – 200mm Foil Width:≤150mm x Thickness:≤0.13mm Plate Width:≥150mm x Thickness:≥4.8mm Sheet Width:≥150mm x Thickness: 0.13-4.8mm Strip Width:≤150mm x Thickness:0.13-4.8mm |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical analysis, Tensile test, Intergranular corrosion test, Flatness %=(H/L) x 100, Metallographic examination |

Packing

Packed in plywood boxes.

Application

Aerospace: Utilized in rocket engine components, such as nozzles and combustion chambers, due to its high-temperature strength and creep resistance.

Gas Turbines: Finds application in high-performance gas turbine engines for components like blades and vanes that experience extreme temperatures and stresses.

Nuclear Industry: Used in specific nuclear reactor applications where high-temperature strength and corrosion resistance are crucial.

Chemical Processing: Employed in some high-temperature chemical processing equipment due to its strength and corrosion resistance.