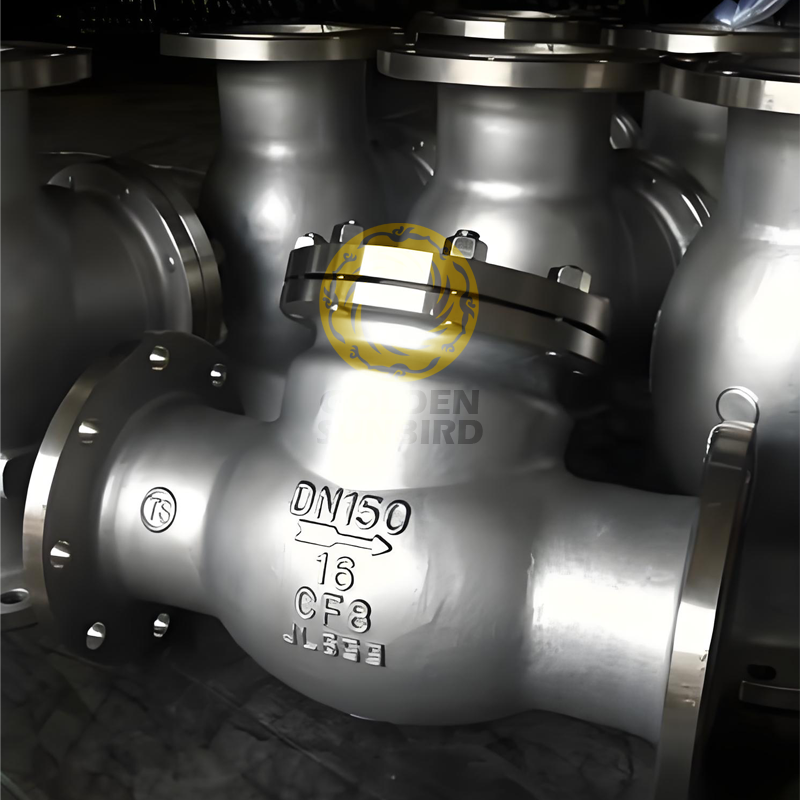

Stainless Steel Check Valve

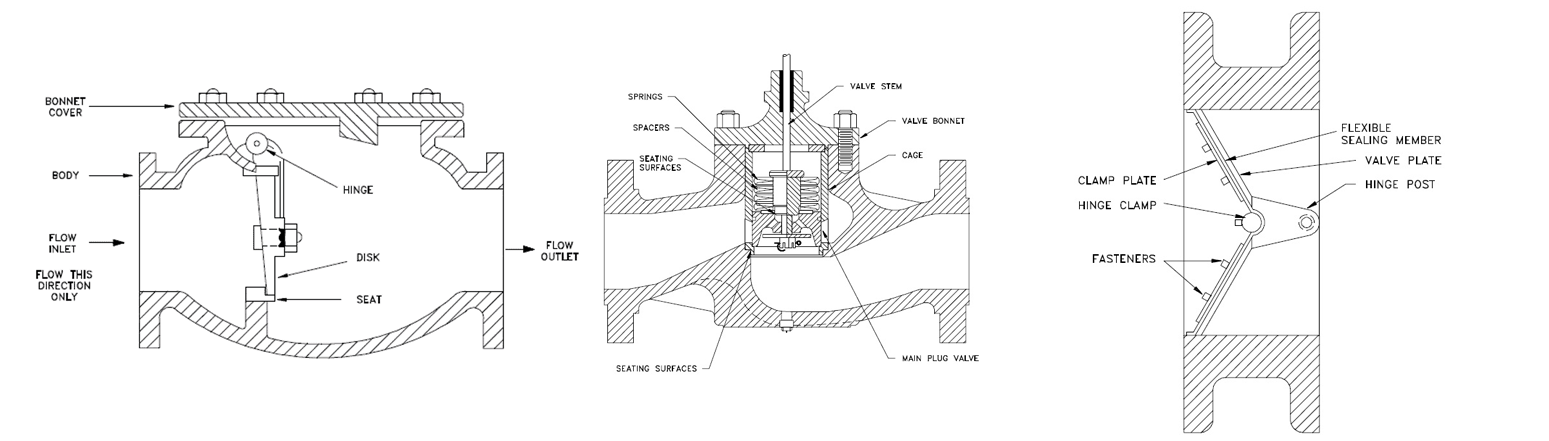

- Swing Check, Lift Check or Piston, Wafer Check

- Pressure Ratings: PN6, PN10, PN16, PN25, PN40; Class 150, 300, 400, 600, 900, 1500, 2500

Features

Stainless Steel Check Valve

Technical Specifications

| Category | Details |

| Valve Type | Stainless Steel Check Valve |

| Design Standard | API 6D: Pipeline Valves API 594: Check Valves ASME B16.34: Flanged, Threaded, and Welded End Valves |

| Manufacturing Standard | ISO 9001: Quality Management Systems |

| Inspection and Test Standard | API 598: Valve Inspection and Testing ISO 5208: Pressure Testing of Metallic Valves EN 12266: Industrial Valves – Testing of Metallic Valves |

| Size Range | Typically from 1/2 inch to 48 inches |

| Pressure Rating | ANSI Class 150 to Class 2500 PN10 to PN420 |

| Connection Type | Flanged (ASME B16.5), Threaded (NPT, BSP), Grooved End, Socket Weld |

| Body Material | Stainless Steel (F304/F304L, F316, F316L, CF8, CF8M, Duplex) |

| Disc | Material: Stainless Steel (304, 316, 316L) Types: Swing, Lift, Piston, Ball, Dual Plate |

| Stem | Material: Stainless Steel (304, 316, 316L) |

| Seat | Material: PTFE, EPDM, NBR, Metal (e.g., Stainless Steel, Inconel) |

| Packing | Material: PTFE, Graphite |

| Gasket | Material: PTFE, Graphite, Spiral Wound Gasket |

| Actuation Methods | Self-actuated (automatic) |

| Applications | Chemical Processing, Water Treatment, Oil and Gas, HVAC, Food and Beverage, Power Generation |

| Features | One-way Flow Operation, Low-Pressure Drop, Bubble-Tight Shutoff, Fire Safe Design (API 607), Anti-Static Device |

| Operating Temperature | Typically -40°C to 400°C (-40°F to 752°F), but can vary based on materials and design |

| Certifications | CE Marking |

| Maintenance | Low Maintenance due to Simple Design, Easily Replaceable Seats and Seals |