Stainless Steel Plug Valve

- Lubricated, Non-lubricated, Multi-Port, Eccentric

- Pressure Ratings: PN6, PN10, PN16, PN25, PN40; Class 150, 300, 400, 600, 900, 1500, 2500

Features

Stainless Steel Plug Valve

Technical Specifications

| Category | Details |

| Valve Type | Stainless Steel Plug Valve |

| Design Standard | ASME B16.34: Flanged, Threaded, and Welded End Valves API 6D: Pipeline Valves API 599: Metal Plug Valves |

| Manufacturing Standard | ASME B16.34: Flanged, Threaded, and Welded End Valves ISO 9001: Quality Management Systems |

| Inspection and Test Standard | API 598: Valve Inspection and Testing ISO 5208: Pressure Testing of Metallic Valves EN 12266: Industrial Valves – Testing of Metallic Valves |

| Size Range | Typically from ½ inch to 24 inches |

| Pressure Rating | ANSI Class 150 to Class 2500 PN10 to PN40 |

| Connection Type | Flanged (ASME B16.5), Threaded (ASME B1.20.1), Socket Weld (ASME B16.11), Butt Weld (ASME B16.25) |

| Body Material | Stainless Steel (F304/F304L, F316, F316L, CF8, CF8M) |

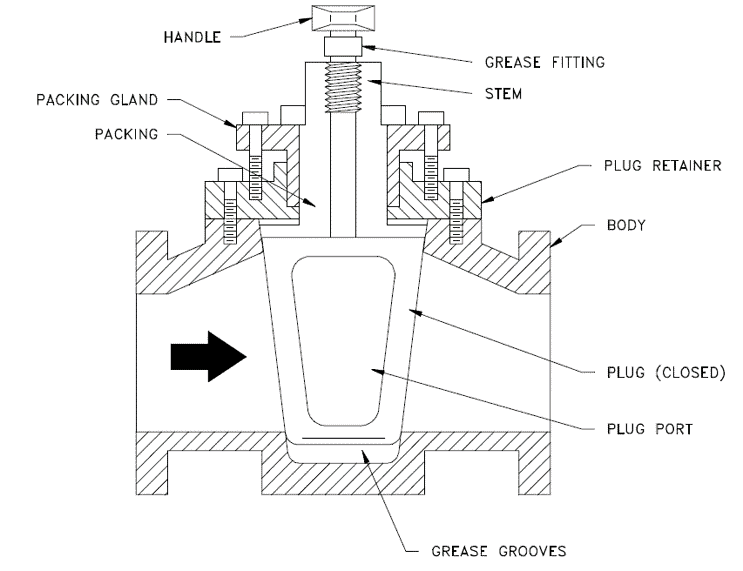

| Bonnet | Material: Stainless Steel (304, 316, 316L) Types: Bolted Bonnet, Integral Bonnet |

| Stem | Material: Stainless Steel (304, 316, 316L) |

| Seat | Material: PTFE, PEEK, Metal (Hardened Stainless Steel) |

| Plug | Material: Stainless Steel (304, 316, 316L) Types: Lubricated Plug, Non-Lubricated Plug |

| Packing | Material: PTFE, Graphite |

| Gasket | Material: Spiral Wound Gasket, PTFE, Graphite |

| Actuation Methods | Manual (Hand Lever), Pneumatic Actuator, Electric Actuator, Hydraulic Actuator |

| Applications | Chemical Processing, Water Treatment, Oil and Gas, Power Generation, Pharmaceutical |

| Features | Quarter-Turn Operation, Bubble-Tight Shutoff, Fire Safe Design (API 607), Anti-Static Device |

| Operating Temperature | Typically -20°C to 260°C (-4°F to 500°F), but can vary based on materials and design |

| Certifications | CE Marking |

| Maintenance | Low Maintenance due to Simple Design, Easily Replaceable Seats and Seals |