Golden Sunbird Metals is China’s leading supplier of Stainless Steels, specializing in high-quality Ferritic Stainless Steel (TP409, TP430, TP434, TP436, TP439, TP444), Martensitic Stainless Steel (TP410, TP420, TP431, TP440A, TP440B, TP440C, TP416), Austenitic Stainless Steel (TP304/304L, TP309S, TP310S, TP316/316L, TP317/317L, TP321, TP347/347H, TP348/348H, UNS S31254, UNS S32654, UNS S38815) and Duplex Stainless Steel (UNS S31803, UNS S32205, UNS S32750, UNS S32760, UNS S32304) materials. We offer stainless steel tubes, plates, bars, pipe fittings, flanges, and valves widely used in oil and gas, petrochemical, acid and alkali, salt, construction, decoration, furniture, and machining. Our stainless steel products demonstrate exceptional performance and durability in harsh environments and demanding conditions, ensuring the longevity and safety of equipment. Choosing Golden Sunbird Metals means choosing high standards of quality and service. Contact us at [email protected] to learn how our stainless steel solutions can elevate your project.

GOLDEN SUNBIRD METALS’ SUPPLY LIST OF STAINLESS STEEL PRODUCTS:

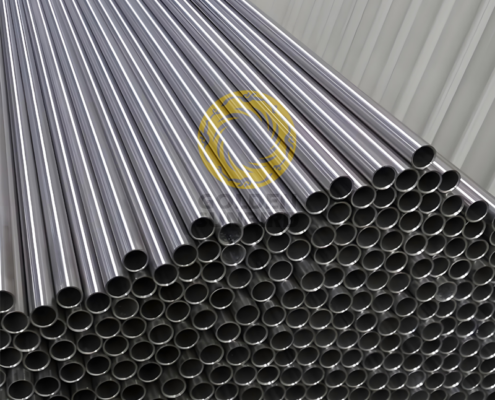

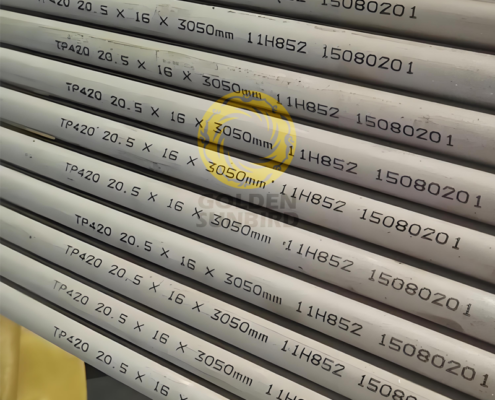

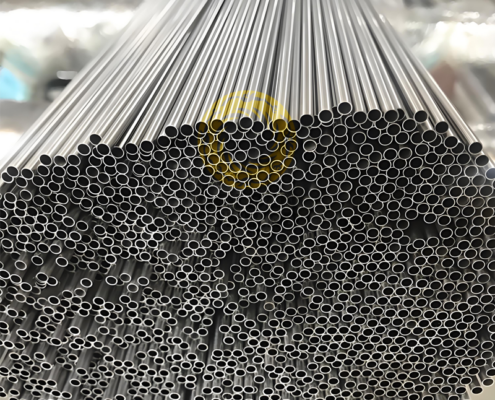

Stainless Steel Pipe and Tube

Known for their corrosion resistance, high strength, and versatility, making them essential for applications in industries such as oil and gas, chemical processing, food processing, and construction.

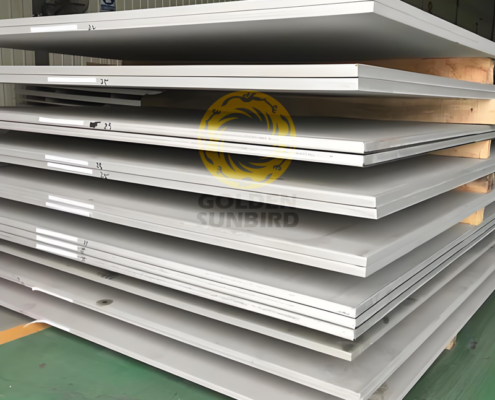

Stainless Steel Plate and Sheet

They offer excellent corrosion resistance, durability, and versatility, making them indispensable for industrial machinery and equipment applications for architectural and decorative uses.

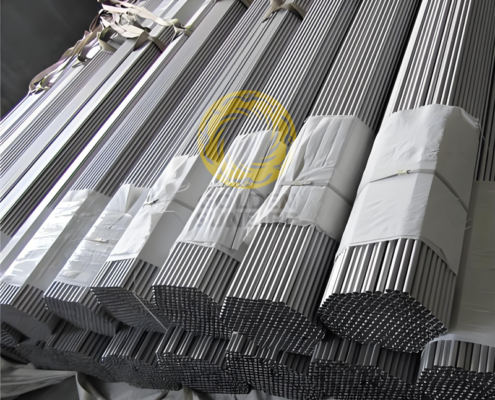

Stainless Steel Bar

Valued for its strength, corrosion resistance, and machinability, making it essential in applications such as construction, aerospace, automotive, and manufacturing of precision components.

Stainless Steel Pipe Fittings

Prized for their durability, corrosion resistance, and suitability for demanding environments, they are essential for connecting and controlling fluid flow in industries including chemical processing, oil and gas, and food processing.

Stainless Steel Flanges

They are crucially used in industries such as oil and gas, petrochemicals, and power generation because of their robustness, corrosion resistance, and ability to facilitate secure connections in piping systems.

Stainless Steel Valves

Offering excellent corrosion resistance, durability, high-temperature and pressure tolerance, and ease of maintenance, making them ideal for use in the oil and gas, chemical processing, power generation, water treatment, food and beverage, pharmaceutical, marine, HVAC, and mining industries.

FAQs

What Are Stainless Steels?

Stainless steels are a group of iron-based alloys known for their corrosion resistance, their most prominent property. They typically contain at least 10.5% chromium, which forms a passive layer of chromium oxide on the surface of the steel, preventing further surface corrosion and blocking corrosion from spreading into the metal’s internal structure.

Here are some key characteristics and types of stainless steels:

Corrosion Resistance: The chromium content allows the formation of a thin, invisible oxide layer on the surface, which protects the underlying material from corrosion.

Strength: Stainless steels can be highly durable and robust, making them suitable for various applications.

Temperature Resistance: Many stainless steels can withstand high temperatures.

Aesthetic Appeal: They have a shiny, attractive appearance, making them popular for architectural and consumer applications.

Hygienic Properties: They are easy to clean and sterilize and essential for medical and food-related uses.

Why Are Stainless Steels Used?

Stainless steels are used for various reasons stemming from their unique properties and advantages. Here are the primary reasons why stainless steels are widely utilized across different industries:

1. Corrosion Resistance

Oxide Layer Protection: Chromium in stainless steel forms a passive oxide layer on the surface, preventing corrosion. This makes stainless steel ideal for environments that otherwise cause rust and deterioration in other metals.

Wide Range of Environments: Stainless steels can resist corrosion in various settings, including acidic, alkaline, and marine environments.

2. Strength and Durability

High Tensile Strength: Many stainless steel grades offer excellent strength, which can be maintained at high and low temperatures.

Longevity: The durability of stainless steel ensures long service life, reducing the need for frequent replacements.

3. Hygiene and Cleanliness

Easy to Clean: Stainless steel has a smooth surface that is easy to clean and sterilize, making it ideal for medical equipment, food processing, and kitchen utensils.

Non-porous: Its non-porous nature prevents bacteria and other pathogens from adhering to surfaces, maintaining hygiene standards.

4. Aesthetic Appeal

Attractive Finish: Stainless steel has a bright, modern appearance and is often used in architecture and consumer goods for its aesthetic appeal.

Variety of Finishes: It can be polished to a high shine or given a matte or brushed finish, providing flexibility in design.

5. Heat and Fire Resistance

High Melting Point: Stainless steels can withstand high temperatures without losing strength or shape.

Fire Resistance: They are used in applications requiring fire-resistant materials, such as building facades and industrial equipment.

6. Sustainability

Recyclability: Stainless steel is 100% recyclable. Scraps can be reprocessed into new stainless steel without any loss in quality, making it an environmentally friendly option.

Longevity: Stainless steel’s long lifespan reduces waste and the need for frequent replacements, contributing to sustainability.

7. Versatility and Variety

Multiple Grades: There are numerous grades of stainless steel, each tailored for specific applications. This versatility ensures a suitable grade for almost any environment or requirement.

Adaptability: Stainless steels can be easily fabricated, welded, and machined, making them adaptable to various manufacturing processes and applications.

8. Cost-Effectiveness

Low Maintenance: Despite higher initial costs, stainless steel’s low maintenance and long life make it cost-effective in the long run.

Reduced Downtime: Its durability and resistance to damage reduce the need for repairs and downtime in industrial applications.

How Are Stainless Steels Made?

The production of stainless steel involves several key steps, each crucial to ensuring the final product possesses the desired strength, durability, and corrosion resistance. Here is an overview of the stainless steel manufacturing process:

1. Raw Material Preparation

Iron Ore and Other Raw Materials: Stainless steel production starts with iron ore, chromium, nickel, molybdenum, silicon, and other alloying elements. Scrap metal is also used to ensure efficient resource utilization.

Blending: The raw materials are carefully blended to achieve the desired chemical composition.

2. Melting

Electric Arc Furnace (EAF): The blended materials are melted in an electric arc furnace, where high-temperature electric arcs melt the metal. This process can take several hours.

Refining: During the melting process, refining agents are added to remove impurities such as carbon, sulfur, and phosphorus. Oxygen may be blown into the furnace to oxidize these impurities.

3. Tapping and Casting

Tapping: Once the metal is fully melted and refined, it is tapped from the furnace. The molten steel is poured into a ladle.

Secondary Refining (AOD or VOD): The molten steel often undergoes secondary refining processes like Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) to achieve precise control over the chemical composition and to reduce carbon content further.

Casting: The refined molten steel is then cast into semi-finished forms such as billets, blooms, or slabs. This can be done through continuous casting or ingot casting.

4. Forming

Hot Rolling: The semi-finished steel forms are heated and passed through rolling mills to create sheets, plates, bars, or wires. This hot rolling process reduces the thickness and refines the grain structure.

Cold Rolling: For specific applications, the steel undergoes cold rolling, which involves rolling the steel at room temperature to achieve tighter tolerances and improved surface finish.

5. Heat Treatment

Annealing: The rolled steel is subjected to annealing, a heat treatment process that involves heating it to a high temperature and cooling it slowly. This process relieves internal stresses, enhances ductility, and improves corrosion resistance.

Quenching and Tempering: Some grades of stainless steel may undergo quenching (rapid cooling) and tempering (controlled reheating) to achieve specific mechanical properties.

6. Descaling

Pickling: The annealed stainless steel is often covered with scale and impurities, which are removed through pickling. This involves immersing the steel in an acid (typically hydrochloric or sulfuric acid) to clean the surface.

Electropolishing: Electropolishing may be used to achieve a superior finish. In this process, the steel is subjected to an electrochemical process that smooths and brightens the surface.

7. Cutting and Shaping

Cutting: The steel is cut into the desired shapes and sizes using various cutting methods, such as shearing, sawing, or laser cutting.

Shaping: Further shaping processes, such as bending, forming, or machining, create the final product.

8. Finishing

Surface Finishing: Stainless steel can undergo various finishing processes, such as grinding, polishing, or brushing, to achieve the desired surface texture and appearance.

Coating: Some applications may require additional coatings, such as passivation or application of protective films, to enhance corrosion resistance further.

9. Quality Control and Testing

Inspection: The finished stainless steel products are subjected to rigorous quality control measures, including visual inspection, mechanical testing, and chemical analysis, to ensure they meet the specified standards and requirements.

Non-destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and eddy current testing may be used to detect internal defects and ensure the integrity of the material.

10. Packaging and Distribution

Packaging: The stainless steel products are carefully packaged to protect them from damage during transportation.

Distribution: The products are distributed to various industries for applications ranging from construction and automotive to medical devices and kitchen appliances.

What Are the Types of Stainless Steels?

1. Austenitic Stainless Steels:

Composition: Typically contains 16-26% chromium and 6-22% nickel.

Properties: Excellent corrosion resistance, good formability, and weldability.

Examples: 304, 316 grades.

Applications: Food processing equipment, kitchen utensils, medical devices.

2. Ferritic Stainless Steels:

Composition: Contain 10.5-27% chromium with little or no nickel.

Properties: Good corrosion resistance, magnetic, and less ductile than austenitic grades.

Examples: 430 grade.

Applications: Automotive parts, industrial equipment, and home appliances.

3. Martensitic Stainless Steels:

Composition: Contain 11-17% chromium and higher carbon content.

Properties: High strength, hardness, moderate corrosion resistance, and magnetic.

Examples: 410, 420 grades.

Applications: Cutlery, surgical instruments, and turbine blades.

4. Duplex Stainless Steels:

Composition: Balanced mixture of austenitic and ferritic structures, with 19-28% chromium and 5-8% nickel.

Properties: High strength and excellent resistance to stress corrosion cracking.

Examples: 2205 grade.

Applications: Chemical processing, oil and gas industry, marine environments.

5. Precipitation-Hardening Stainless Steels:

Composition: They contain chromium and nickel with additional elements like copper, which allows them to be hardened by heat treatment.

Properties: High strength and good corrosion resistance.

Examples: 17-4PH.

Applications: Aerospace components, mechanical components.

How Do You Care for and Maintain Stainless Steels?

Caring for and maintaining stainless steels involves several key practices to ensure their longevity and aesthetic appeal. Here’s a comprehensive guide:

General Maintenance

Regular Cleaning:

Use mild soap or detergent with warm water for routine cleaning.

Wipe surfaces with a soft cloth or sponge.

Rinse thoroughly with clean water to remove any soap residue.

Dry with a clean towel or cloth to prevent water spots and streaks.

Avoiding Abrasives:

Do not use abrasive cleaners, steel wool, or scouring pads as they can scratch the surface.

For stubborn stains, use a non-abrasive cleaning powder or paste and a soft cloth.

Stain Removal:

For minor stains or fingerprints, a glass cleaner or a solution of vinegar and water can be effective.

For more persistent stains, a paste of baking soda and water applied with a soft cloth can help.

Specialized Care

Removing Rust:

Despite its name, stainless steel can develop rust spots. Use a commercial rust remover or a mixture of baking soda and lemon juice.

Apply the solution with a soft cloth and gently rub the rusted area. Rinse and dry thoroughly.

Polishing:

To maintain a shiny finish, use a stainless steel polish or a solution of olive oil and a few drops of lemon juice.

Apply with a soft cloth and buff to a shine.

Protective Coatings:

Applying a thin layer of car wax or a stainless steel sealant can help protect against stains and fingerprints.

Ensure the surface is clean before applying the coating.

Preventative Measures

Avoiding Chlorides:

Chlorides, found in salt and some cleaners, can cause pitting and corrosion. Rinse the steel thoroughly if it comes into contact with salt or chlorine-based cleaners.

Controlling Moisture:

Keep stainless steel surfaces as dry as possible to prevent water spots and potential rusting.

In areas with high humidity, regular drying and the use of a dehumidifier can help.

Minimizing Contact with Iron:

Prevent contact with iron or steel objects which can cause rust transfer. This includes iron nails, steel wool, and other tools.

Maintenance Frequency

Daily: Wipe down frequently used surfaces to remove fingerprints and smudges.

Weekly: Perform a more thorough cleaning with soap and water, and inspect for any signs of rust or stains.

Monthly: Polish the surface and apply a protective coating if necessary.

Annually: Inspect for any signs of damage or corrosion, and address any issues promptly.

Specific Applications

Kitchen Appliances and Surfaces:

Regularly clean and dry to prevent food stains and water spots.

Use a dedicated stainless steel cleaner for a streak-free finish.

Outdoor Structures:

Clean regularly to remove environmental contaminants.

Apply a protective wax or sealant to shield against weather elements.

Industrial Equipment:

Follow manufacturer guidelines for cleaning and maintenance.

Regularly inspect for signs of wear, corrosion, or mechanical damage.

Can Stainless Steels Be Recycled?

Yes, stainless steels can be recycled. Stainless steel is one of the most recyclable materials available and has a high recycling rate. Here are some critical points about recycling stainless steel:

High Recyclability

- Infinite Recycling: Stainless steel can be recycled indefinitely without losing its properties or performance.

- High Recycling Rate: Many stainless steel products contain recycled material, often between 60-80%.

Recycling Process

- Collection: Stainless steel scrap is collected from various sources, such as manufacturing waste, end-of-life products, and industrial equipment.

- Sorting: The scrap is sorted based on the type and grade of stainless steel.

- Shredding: The sorted scrap is shredded into smaller pieces to facilitate melting.

- Melting: The shredded scrap is melted in an electric arc furnace.

- Refining: The molten metal is refined to remove impurities and adjust the composition to meet specific standards.

- Casting: The refined molten stainless steel is cast into slabs or other forms for further processing into new products.

Environmental Benefits

- Resource Conservation: Recycling stainless steel reduces the need for raw materials like iron ore, nickel, and chromium.

- Energy Savings: Recycling consumes less energy than producing stainless steel from raw materials.

- Reduced Emissions: Recycling stainless steel helps lower greenhouse gas emissions and other pollutants associated with mining and processing raw materials.

Economic Benefits

- Cost Efficiency: Recycling stainless steel can be more cost-effective than producing new stainless steel from raw materials.

- Market Value: Stainless steel scrap has significant market value, creating economic incentives for recycling.

Applications of Recycled Stainless Steel

Recycled stainless steel is used in a wide range of applications, including:

- Construction and infrastructure projects.

- Manufacturing of kitchenware and appliances.

- Automotive and transportation industries.

- Industrial equipment and machinery.

By recycling stainless steel, we can conserve resources, save energy, and reduce environmental impact while maintaining the quality and performance of this versatile material.

What Are Some Common Applications of Stainless Steels?

Stainless steels of various kinds are used in thousands of applications. The following gives just a flavour of the full range:

- Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

- Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections, reinforcement bar, lighting columns, lintels, masonry supports

- Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles.

- Chemical/Pharmaceutical – pressure vessels, process piping.

- Oil and Gas – platform accommodation, cable trays, subsea pipelines.

- Medical – Surgical instruments, surgical implants, MRI scanners.

- Food and Drink – Catering equipment, brewing, distilling, food processing.

- Water – Water and sewage treatment, water tubing, hot water tanks.

- General – springs, fasteners (bolts, nuts and washers), wire

What Environmental Impact Do Stainless Steels Have?

Stainless steel has several environmental impacts throughout its lifecycle, from production to end-of-life recycling. Here’s an overview of these impacts:

Production Phase

- Raw Material Extraction:

- Mining: The extraction of iron ore, nickel, chromium, and other raw materials used in stainless steel can destroy habitats, cause soil erosion, and pollute the environment.

- Energy Consumption: Mining and processing raw materials are energy-intensive activities contributing to greenhouse gas emissions and environmental degradation.

- Manufacturing:

- Energy Use: Producing stainless steel requires significant energy consumption, primarily from electricity and fossil fuels, which contribute to carbon dioxide (CO₂) emissions.

- Water Usage: Large volumes of water are used in manufacturing, which can lead to water scarcity and pollution if not managed properly.

- Air Emissions: The production process releases CO₂, sulfur oxides (SOx), and nitrogen oxides (NOx), which can contribute to air pollution and climate change.

Usage Phase

- Durability:

- Longevity: Stainless steel is highly durable and corrosion-resistant, reducing the need for frequent replacements and maintenance. This longevity helps mitigate the environmental impact associated with manufacturing new products.

- Maintenance: The ease of cleaning and maintaining stainless steel can reduce the use of harsh chemicals and cleaning agents, lessening the potential for environmental pollution.

- Recyclability:

- High Recycling Rate: Stainless steel has a high recycling rate, often containing 60-80% recycled material. This reduces the demand for virgin raw materials and the environmental impacts of mining and processing.

- Energy Savings: Recycling stainless steel uses significantly less energy than producing new stainless steel from raw materials, leading to lower greenhouse gas emissions.

End-of-Life Phase

- Recycling:

- Closed-Loop Recycling: Stainless steel can be recycled indefinitely without losing its properties, making it a sustainable material choice. The recycling process involves melting down scrap metal and reforming it into new products.

- Resource Conservation: Recycling stainless steel conserves natural resources and reduces the environmental impact of raw material extraction and processing.

- Waste Management:

- Reduced Landfill: Stainless steel’s high recyclability means less waste ends up in landfills, reducing the environmental burden of waste management.

- Economic Incentives: The market value of stainless steel scrap creates economic incentives for its collection and recycling, further promoting sustainable practices.

Overall Environmental Impact

While stainless steel production has significant environmental impacts due to energy consumption, emissions, and resource use, its high durability, low maintenance requirements, and excellent recyclability make it a relatively sustainable material over its entire lifecycle. The environmental benefits of recycling and the long lifespan of stainless steel products help offset some of the initial environmental costs associated with its production.

To further mitigate its environmental impact, the industry is making efforts to improve energy efficiency, reduce emissions, and enhance recycling processes.

How Does the Cost of Stainless Steels Compare to Other Metals?

The cost of stainless steels can vary significantly compared to other metals due to factors like raw material prices, processing costs, and market demand. Here’s a breakdown of how stainless steel compares to some common metals:

1. Carbon Steel

- Cost Comparison: Carbon steel is generally cheaper than stainless steel.

- Reasons:

- Material Composition: Carbon steel lacks the alloying elements (like chromium and nickel) that make stainless steel more expensive.

- Production Process: Carbon steel is less complex and energy-intensive than stainless steel.

- Usage: Preferred in applications where corrosion resistance is less critical, such as in the construction and automotive industries.

2. Aluminum

- Cost Comparison: Aluminum can be either more or less expensive than stainless steel, depending on the specific alloy and market conditions.

- Reasons:

- Material Properties: Aluminum is lighter and often used in applications where weight reduction is crucial despite its higher cost.

- Processing: While aluminum is generally easier to form and work with, some high-strength aluminum alloys can be costly.

- Usage: Common in aerospace, transportation, and packaging due to its lightweight and corrosion resistance.

3. Copper

- Cost Comparison: Copper is usually more expensive than stainless steel.

- Reasons:

- Raw Material Cost: Copper ore is generally more expensive than the raw materials used in stainless steel.

- Demand: Copper has high demand in electrical applications due to its excellent conductivity.

- Usage: Widely used in electrical wiring, plumbing, and heating systems.

4. Titanium

- Cost Comparison: Titanium is significantly more expensive than stainless steel.

- Reasons:

- Material Properties: Titanium has excellent strength-to-weight ratio and corrosion resistance, especially in extreme environments.

- Production: Extracting and processing titanium is complex and energy-intensive.

- Usage: Used in aerospace, medical implants, and high-performance applications.

5. Brass

- Cost Comparison: Brass is generally more expensive than stainless steel.

- Reasons:

- Material Composition: Brass is an alloy of copper and zinc, both relatively expensive.

- Properties: Brass is valued for its workability and aesthetic appeal.

- Usage: Used in decorative items, plumbing, and musical instruments.

6. Nickel Alloys

- Cost Comparison: Nickel alloys are typically more expensive than stainless steel.

- Reasons:

- Material Properties: High-performance nickel alloys offer superior corrosion resistance and mechanical properties in extreme environments.

- Production: These alloys often involve complex manufacturing processes.

- Usage: Common in chemical processing, aerospace, and marine applications.

Factors Influencing Cost

- Raw Material Prices: The cost of alloying elements like chromium, nickel, and molybdenum can significantly impact the price of stainless steel.

- Production Complexity: Advanced manufacturing techniques and treatments (e.g., heat treatments and cold working) increase the overall cost.

- Market Demand: Fluctuations in demand across different industries can influence prices.

- Recycling Content: The proportion of recycled material used can affect costs, as recycled stainless steel is generally cheaper.

Conclusion

- Stainless Steel vs. Carbon Steel: More expensive due to alloying elements and processing costs.

- Stainless Steel vs. Aluminum: Variable; depends on specific alloys and application requirements.

- Stainless Steel vs. Copper, Brass, Titanium, and Nickel Alloys: Generally less expensive but varies based on specific application needs and properties required.

While stainless steel is often more expensive than carbon steel, its cost is justified by its superior corrosion resistance, durability, and overall performance in various applications. When choosing between metals, it’s important to consider the initial material cost and the lifecycle cost, including maintenance, longevity, and performance in the intended application.