Welcome to Golden Sunbird Metals, your trusted titanium alloy supplier in China. With over 13 years of expertise, we deliver precision-engineered titanium products designed for the demanding realms of aerospace, automotive, chemical processing, medical devices, and marine engineering. Our extensive range includes pipes, tubes, plates, bars, wires, forgings, flanges, pipe fittings, fasteners, and anodes, celebrated for their High Strength, Corrosion Resistance, Lightweight, and Biocompatibility properties. For bulk purchases of high-quality titanium alloys at competitive prices, contact us at [email protected]. Choose Golden Sunbird Metals to elevate your projects with reliable and innovative titanium solutions.

Golden Sunbird Metals’ Supply List of Titanium Alloy Products:

Titanium Pipe and Tube

Known for their high strength, lightweight, and exceptional corrosion resistance, titanium pipes, and tubes are widely used in aerospace, chemical processing, and marine industries. Their high thermal stability also makes them suitable for high-temperature applications.

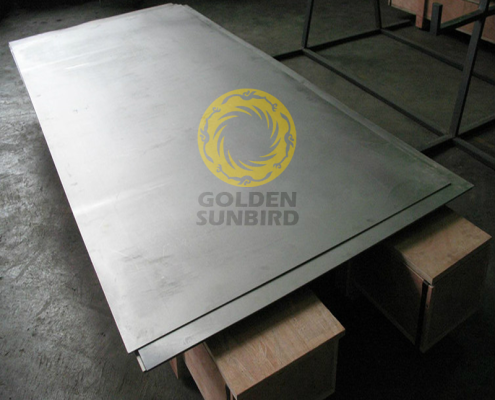

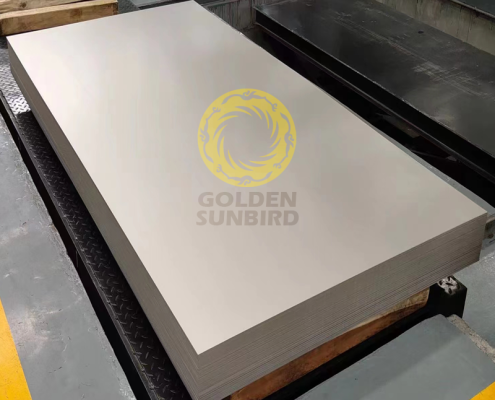

Titanium Plate and Sheet

Titanium plates and sheets are favored for their excellent strength-to-density ratio and corrosion resistance. Due to their ability to withstand extreme conditions, they are used in aerospace structures, medical devices, and armor.

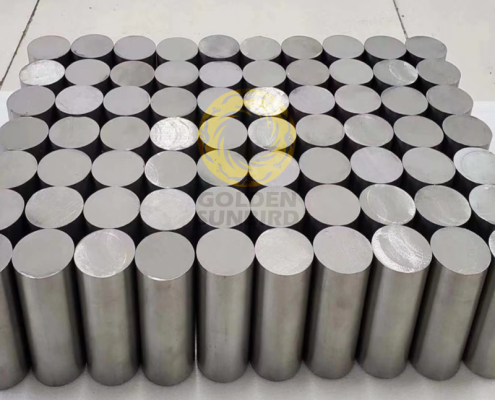

Titanium Bar

Titanium bars boast high strength, low weight, and outstanding corrosion resistance. They find applications in the aerospace, medical, and sports equipment industries, where durability and weight savings are crucial.

Titanium Wire

Known for its strength, lightweight, and biocompatibility, titanium wire is commonly used in medical implants, eyeglass frames, and various aerospace applications. It’s also utilized in welding, where its corrosion resistance is essential.

Titanium Pipe Fittings

Recognized for their outstanding resistance to corrosion, lightweight composition, and impressive strength-to-weight ratio, titanium pipe fittings are indispensable components in various industries, including chemical processing, oil and gas, and aerospace. They are crucial in constructing pipelines and other systems where durability and reliability under demanding conditions are paramount.

Titanium Flanges

Titanium flanges are highly esteemed for their exceptional corrosion resistance, lightweight design, and remarkable strength-to-weight ratio. Widely utilized in industries such as chemical processing, oil and gas, and aerospace, titanium flanges are integral components in the assembly of piping systems and critical connections. Their ability to withstand corrosive environments, high temperatures, and extreme pressures ensures optimal performance and longevity in demanding applications.

Titanium Fasteners

These fasteners are celebrated for their strength, lightweight, and corrosion resistance, making them ideal for aerospace, automotive, and marine applications. They ensure the durability and integrity of assemblies in corrosive environments.

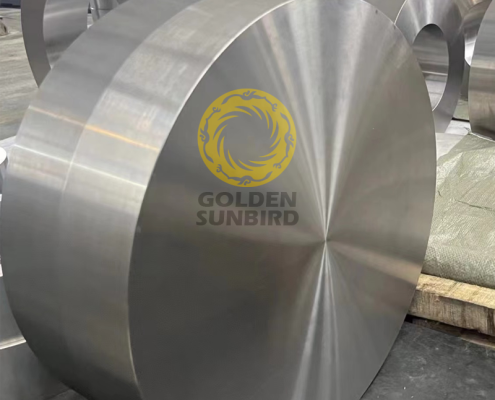

Titanium Forgings

Forged titanium parts are sought for their high strength, low weight, and exceptional corrosion resistance. They are used in aerospace components, sports equipment, and industrial machinery for their durability and ability to perform under stress.

Titanium Anode

Titanium anodes are crucial in electrochemical processes, such as cathodic protection and water treatment. They are valued for their durability, efficiency, and corrosion resistance, significantly outperforming other materials in electrolytic environments.

FAQs

What Are Titanium Alloys?

Titanium alloys are materials formed by combining titanium with other metals and elements, enhancing their properties to meet specific requirements. These alloys are known for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures without losing their integrity. They are widely used in aerospace, medical implants, automotive components, and in harsh chemical environments.

- Key Points:

- Titanium alloys are made by mixing titanium with other metals.

- They have a high strength-to-weight ratio and are highly corrosion-resistant.

- Their applications range from aerospace to medical implants.

Why Are Titanium Alloys Used in Aerospace?

In the aerospace industry, titanium alloys are invaluable due to their lightweight, high strength, and resistance to corrosion and temperature changes. These properties allow for the creation of aircraft and spacecraft parts that can endure extreme conditions while minimizing weight, which is crucial for fuel efficiency and performance. Specifically, titanium alloys are used in engines, airframes, and critical fasteners.

- Key Points:

- Lightweight and strong, making them ideal for aerospace applications.

- Resistant to corrosion and temperature variations.

- Used in critical components like engines and airframes.

How Are Titanium Alloys Manufactured?

The manufacturing process of titanium alloys involves several steps, starting with the extraction of titanium from its ores through the Kroll process. This process produces titanium sponge, which is then melted with other metals to form an alloy. Advanced techniques like vacuum arc remelting refine the alloy’s properties. The final product can be shaped into various forms through forging, casting, or machining.

- Key Points:

- The Kroll process is used to extract titanium from its ores.

- Alloys are refined through processes like vacuum arc remelting.

- Titanium alloys can be formed into shapes via forging, casting, or machining.

How Do Titanium Alloys Compare to Steel?

Titanium alloys offer several advantages over steel. They are significantly lighter, which is essential for applications where weight is a critical factor. Titanium is also more corrosion-resistant, making it suitable for use in environments where steel would rapidly degrade. However, titanium alloys tend to be more expensive due to the complexity of their production process and the cost of raw materials. In terms of strength, high-grade titanium alloys can compete with steel, but steel may be preferred in applications where the cost is a significant consideration.

- Key Points:

- Titanium alloys are lighter and more corrosion-resistant than steel.

- They can be more expensive due to complex production processes.

- High-grade titanium alloys can match the strength of steel in certain applications.

Can Titanium Alloys Be Recycled?

Yes, titanium alloys can be recycled, which adds to their appeal from an environmental sustainability perspective. The recycling process involves collecting titanium scrap, which can come from manufacturing processes or end-of-life products, and then melting it down to create new titanium alloy. This process not only conserves raw materials but also requires less energy compared to producing titanium from ore, thereby reducing the environmental footprint.

- Key Points:

- Titanium alloys are recyclable, enhancing their sustainability.

- The recycling process conserves raw materials and saves energy.

- Recycling contributes to reducing the environmental impact of titanium production.

What Are the Medical Applications of Titanium Alloys?

Titanium alloys are widely used in the medical field due to their biocompatibility, which means they can be implanted into the human body without causing adverse reactions. They are used in a variety of medical devices, including joint replacements, dental implants, and bone fixation devices. The strength, corrosion resistance, and compatibility with body tissues make titanium alloys ideal for long-term implantation, contributing to their popularity in medical applications.

- Key Points:

- Titanium alloys are biocompatible, suitable for implants.

- Used in joint replacements, dental implants, and bone fixation devices.

- Their strength, corrosion resistance, and tissue compatibility make them ideal for medical use.