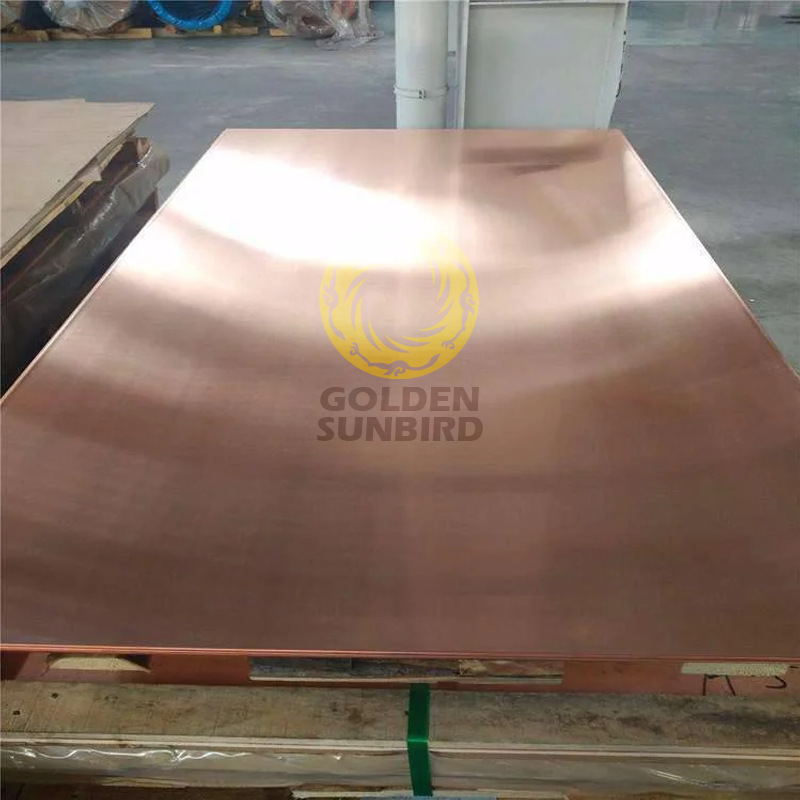

ASTM B194 Copper-Beryllium Alloy Plate

- UNS No. C17000, C17200

- W: 200-1500MM x L: 1000 x 6000mm x T: 0.5-50mm

Features

ASTM B194 Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

Chemical Composition (wt.%)

| Element | Composition % (C17000) | Composition % (C17200) |

|---|---|---|

| Beryllium | 1.60–1.85 | 1.80–2.00 |

| Nickel + Cobalt (min) | 0.20 | 0.20 |

| Nickel + Cobalt + Iron (max) | 0.6 | 0.6 |

| Aluminum (max) | 0.20 | 0.20 |

| Silicon (max) | 0.20 | 0.20 |

| Copper | Remainder | Remainder |

Technical Specifications

| Specification | Value |

| Standard | ASTM B194 Copper-Beryllium Alloy Plate |

| Grade | UNS No. C17000 and C17200 |

| Corrosion Resistance | Excellent |

| Type of Bars | Hot Rolled, Cold Finished |

| Shape of Bars | Alloy Plate, Sheet, Strip , Rolled Bar |

| Density | 8.9g/cm³ |

| Dimension | W: 200-1500MM x L: 1000 x 6000mm x T: 0.5-50mm |

| Length | 1000 – 6000mm |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Analysis, Tensile Test, UT/ET |

Packing

Small diameter packed in plywood box; large diameter packed on plywood pallets.

Application

Components for Aerospace: Due to their high strength-to-weight ratio and resistance to stress relaxation, these alloys are used in aerospace components such as bearings, springs, connectors, and undercarriage parts.

Defense Applications: Their reliability under extreme conditions makes them suitable for components in defense equipment, including guidance systems, satellite and radar systems, and avionic instruments.

Automotive Electronics: Copper-beryllium alloys are used in automotive electronic connectors, sensors, and switches due to their excellent electrical conductivity and resistance to corrosion.

Safety Systems: Components in safety systems, like airbag deployment mechanisms and seatbelt systems, benefit from the high strength and reliability of these materials.

Connectors and Relays: The high conductivity and resistance to oxidation and corrosion make these alloys ideal for connectors, relays, and switches in electronic devices.

Precision Components for Telecommunications: Components that require precision and reliability, such as connectors and spring contacts in mobile phones and other communication devices, often use copper-beryllium alloys.

Tools and Dies: Tools and dies made from copper-beryllium alloys are used in environments where sparking cannot be tolerated, such as in oil and gas extraction, due to the non-sparking properties of these alloys.

Bearings and Bushings: These components benefit from the alloy’s durability and resistance to wear and galling, ensuring longevity and reliability in machinery and engines.

Springs and Membranes: The formability and strength of copper-beryllium alloys allow them to be used in springs, membranes, and other flexible components in consumer electronics, ensuring long-term performance and reliability.

Non-Magnetic Instruments: For environments requiring non-magnetic tools, such as MRI rooms, copper-beryllium alloys provide strength without interfering with magnetic fields.