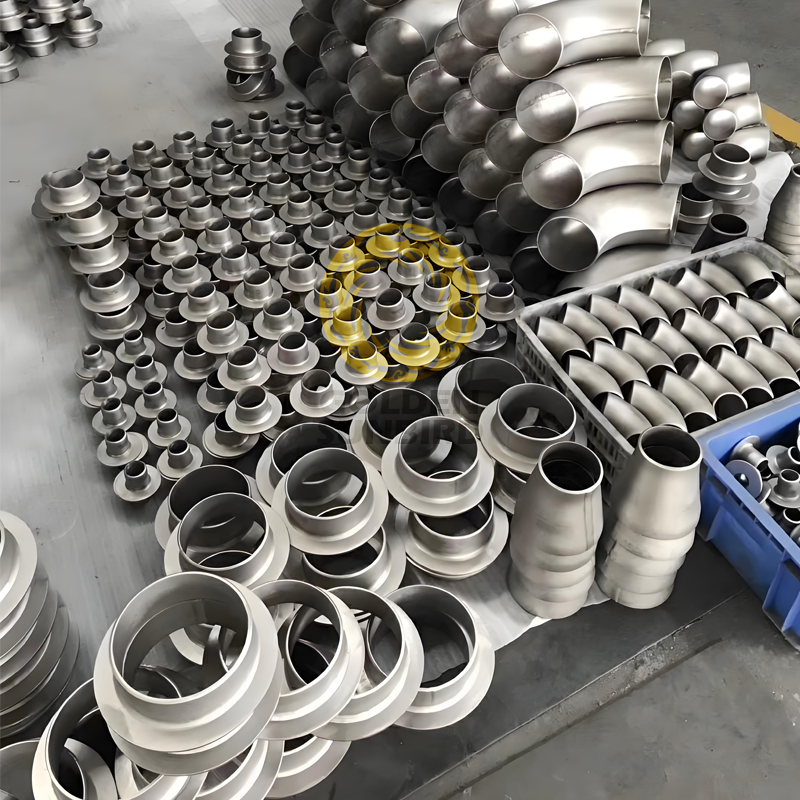

ASTM B363 Titanium and Titanium Alloy Pipe Fittings

- Type: Seamless and Welded Butt-welding Fittings

- Size: NPS 3/8″ – 30″ WT: SCH5S, 10S, 40S, 80S

- Grade 2, CP Ti-2, W.Nr 3.7025, AFNOR T35, BS 2TA1, GOST VT1-0 (ВТ1-0)

- Grade 5, Ti-6Al-4V, W.Nr 3.7165, AFNOR T-A6V, BS TA10-13, GOST BT6 (VT6)

- Grade 7, Ti-0.2Pd, W.Nr 3.7235, BS TA9

- Grade 9, Ti-3Al-2.5V, GOST 3B

- Grade 12, Ti-0.3Mo-0.8Ni, W.Nr 3.7105

- Standard: ANSI/ASME B16.9

Features

ASTM B363 Seamless and Welded Titanium and Titanium Alloy Welding Fittings

Chemical Composition (wt.%)

| Grade | N (max) | C (max) | H (max) | Fe (max) | O (max) | Al | V | Pd | Mo | Ni | Ti |

| WPT2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | – | – | – | – | – | Bal. |

| WPT5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | – | – | – | Bal. |

| WPT7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | – | – | 0.12-0.25 | – | – | Bal. |

| WPT9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | – | – | – | Bal. |

| WPT12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | – | – | – | 0.2-0.4 | 0.6-0.9 | Bal. |

Mechanical Properties

| Grade | Tensile Strength min (ksi [MPa]) |

Yield Strength (0.2% Offset) min (ksi [MPa]) |

Elongation in 2in. or 50mm (min, %) |

| WPT2 | 50 [345] | 40 [275] | 20 |

| WPT5 | 130 [895] | 120 [828] | 10 |

| WPT7 | 50 [345] | 40 [275] | 20 |

| WPT9 | 90 [620] | 70 [483] | 15 |

| WPT12 | 70 [483] | 50 [345] | 18 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B363 Seamless and Welded Titanium and Titanium Alloy Welding Fittings |

| Grade | Grade WPT2, Grade WPT5, Grade WPT7, Grade WPT9, Grade WPT12 |

| Seam Type | Seamless and Welded |

| O.D. | 10.3- 914.4mm (NPS 1/8″ – 36″) |

| W.T. | 1.65- 30.96mm (0.065″-1.219″) SCH 5S, SCH5, SCH10S, SCH10, SCH40S, SCH40, SCH80S, SCH80 |

| Type of Fittings | 45° LR and 90° SR/LR Elbows, 180° Returns, Caps, Equal or Reducing Tees, Concentric/Eccentric Reducers, Lap-joint Stub Ends |

| Density | 4.51 g/cm3 |

| Fitting Standard and Ends Finish | ANSI/ASME B16.9, Butt-welding |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical Analysis, Tensile Test, UT/ET, Dimensional Inspection |

Packing

Plain or beveled ends as per ANSI B16.25 to an angle of 30°+5°/-0°, end with plastic caps or metal protectors, covered or bare, bundled or loosely packed.

Application

Chemical Processing: Titanium pipe fittings are widely used in chemical processing industries due to their excellent corrosion resistance against various corrosive chemicals. They are used in pipelines, reactors, and other equipment handling corrosive substances.

Marine: Titanium’s resistance to corrosion in saltwater makes it suitable for marine applications. Titanium pipe fittings are used in shipbuilding for seawater cooling, piping, and other marine equipment.

Oil and Gas: Titanium pipe fittings are utilized in offshore platforms, subsea pipelines, and processing equipment in the oil and gas industry due to their resistance to corrosive environments and high strength-to-weight ratio.

Power Generation: Titanium pipe fittings are used in power plants, especially in environments exposed to high temperatures and corrosive gases. They are employed in heat exchangers, condensers, and other components.

Desalination: Titanium’s corrosion resistance and ability to withstand high temperatures make it suitable for desalination plants. In desalination processes, titanium pipe fittings are used to construct evaporators, condensers, and piping systems.

Chemical and Petrochemical: Titanium pipe fittings are used in chemical and petrochemical plants to handle corrosive chemicals, acids, and alkalis. They are employed in pipelines, reactors, and other process equipment.