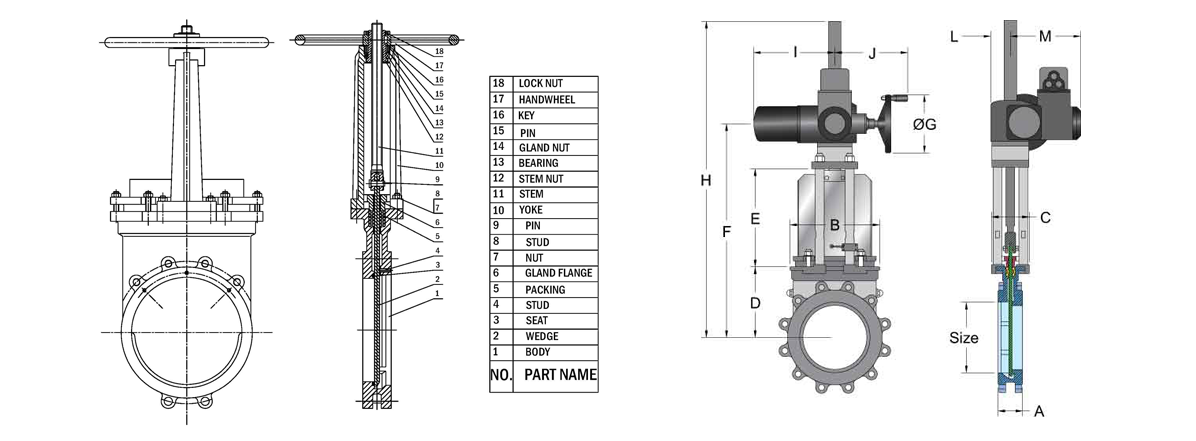

Stainless Steel Knife Gate Valve

- Type: Unidirectional Knife, Bidirectional Knife, Lug Type Knife, Wafer Type Knife, Through Conduit Knife, Slurry Knife, Resilient Seated Knife, Metal Seated Knife

- Pressure Ratings: PN6, PN10, PN16, PN25, PN40; Class 150, 300, 400, 600, 900, 1500, 2500

Features

Stainless Steel Knife Gate Valve

Technical Specifications

| Category | Details |

| Valve Type | Stainless Steel Knife Gate Valve |

| Design Standard | MSS SP-81: Knife Gate Valves for Use in Shutoff Applications ASME B16.5: Pipe Flanges and Flanged Fittings API 609: Butterfly Valves, Lug- and Wafer-Type |

| Manufacturing Standard | ISO 9001: Quality Management Systems |

| Inspection and Test Standard | API 598: Valve Inspection and Testing EN 12266: Industrial Valves – Testing of Metallic Valves |

| Size Range | Typically from 2 inches to 48 inches |

| Pressure Rating | ANSI Class 150 to Class 600 PN10 to PN40 |

| Connection Type | Wafer Type, Lug Type, Flanged (ASME B16.5), Threaded (NPT, BSP) |

| Body Material | Stainless Steel (F304/F304L, F316, F316L, CF8, CF8M) |

| Gate | Material: Stainless Steel (304, 316, 316L) |

| Seat | Material: PTFE, EPDM, NBR, Metal (e.g., Stainless Steel, Inconel) |

| Stem | Material: Stainless Steel (304, 316, 316L) |

| Packing | Material: PTFE, Graphite |

| Gasket | Material: PTFE, Graphite, Spiral Wound Gasket |

| Actuation Methods | Manual (Handwheel or Gear Operator), Pneumatic Actuator, Electric Actuator, Hydraulic Actuator |

| Applications | Pulp and Paper Industry, Mining and Minerals, Wastewater Treatment, Chemical Processing, Power Generation, Bulk Handling |

| Features | Bi-directional Shutoff, Low-Pressure Drop, Non-clogging Gate Design, Replaceable Seats and Seals, Corrosion Resistant |

| Operating Temperature | Typically -20°C to 200°C (-4°F to 392°F), but can vary based on materials and design |

| Certifications | CE Marking |

| Maintenance | Low Maintenance due to Simple Design; Easily Replaceable Seats and Seals |