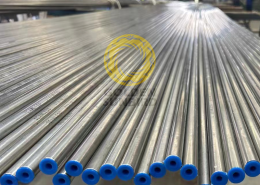

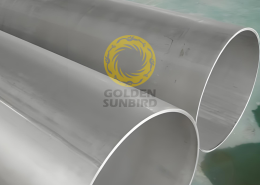

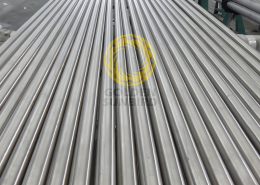

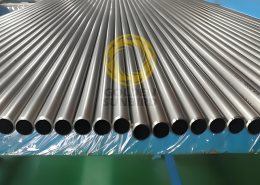

ASTM A249 Welded Stainless Steel Boiler, Heat-Exchanger Tubes

- Grade: TP304/304L, TP309S, TP310S, TP316/316L, TP317/317L, TP321/321H, TP347/347H, TP348/348H

- Tube OD: 4-321mm

- Tube WT: 0.4-8.1mm

- Length: 1000-12000mm

- Type: Welded

Features

ASTM A249 Welded Stainless Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

Chemical Composition (wt.%)

| Grade | UNS | C (%) | Mn (%) | P (%) | S(%) | Si (%) | Cr (%) | Ni (%) | Mo (%) | N (%) | Others |

| TP304 | S30400 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 8.0-11.0 | – | – | – |

| TP304L | S30403 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 8.0-12.0 | – | – | – |

| TP309S | S30908 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 22.0-24.0 | 12.0-15.0 | – | – | – |

| TP310S | S31008 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 24.0-26.0 | 19.0-22.0 | – | – | – |

| TP316 | S31600 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – | – |

| TP316L | S31603 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – | – |

| TP317 | S31700 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | – | – |

| TP317L | S31703 | 0.03 | 2.00 | 0.045 | 0.03 | 1.00 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | – | – |

| TP321 | S32100 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-12.0 | – | 0.1 | Ti 5(C+N)-0.70 |

| TP321H | S32109 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-12.0 | – | 0.1 | Ti 5(C+N)-0.70 |

| TP347 | S34700 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-13.0 | – | – | Cb+Ta 10xC-1.10 |

| TP347H | S34709 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-13.0 | – | – | Cb+Ta 10xC-1.10 |

| TP348 | S34800 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-13.0 | – | – | Cb+Ta 10xC-1.10 |

| TP348H | S34809 | 0.04-0.10 | 2.00 | 0.045 | 0.03 | 1.00 | 17.0-19.0 | 9.0-13.0 | – | – | Cb+Ta 10xC-1.10 |

Mechanical Properties

| Grade | UNS | Tensile Strength (min, MPa) |

Yield Strength (min, MPa) |

Elongation (min, %) |

| TP304 | S30400 | 515 | 205 | 35 |

| TP304L | S30403 | 485 | 170 | 35 |

| TP309S | S30908 | 515 | 205 | 35 |

| TP310S | S31008 | 515 | 205 | 35 |

| TP316 | S31600 | 515 | 205 | 35 |

| TP316L | S31603 | 485 | 170 | 35 |

| TP317 | S31700 | 515 | 205 | 35 |

| TP317L | S31703 | 485 | 170 | 35 |

| TP321 | S32100 | 515 | 205 | 35 |

| TP321H | S32109 | 515 | 205 | 35 |

| TP347 | S34700 | 515 | 205 | 35 |

| TP347H | S34709 | 515 | 205 | 35 |

| TP348 | S34800 | 515 | 205 | 35 |

| TP348H | S34809 | 515 | 205 | 35 |

Technical Specifications

| Specification | Value |

| Standard | ASTM A249/A249M Welded Stainless Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes |

| Grade | TP304/304L, TP309S, TP310S, TP316/316L, TP317/317L, TP321/321H, TP347/347H, TP348/348H |

| Manufacturing Process | Welded |

| Seam Type | Welded |

| Dimension | Tube OD: 4-321mm Tube WT: 0.4-8.1mm |

| Length | 1000-12000mm |

| Delivery Condition | Heating the material and quenching in water or rapidly cooling by other means |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tension tests, Flaring tests, Hydrostatic tests, Air underwater pressure tests, Nondestructive electric tests |

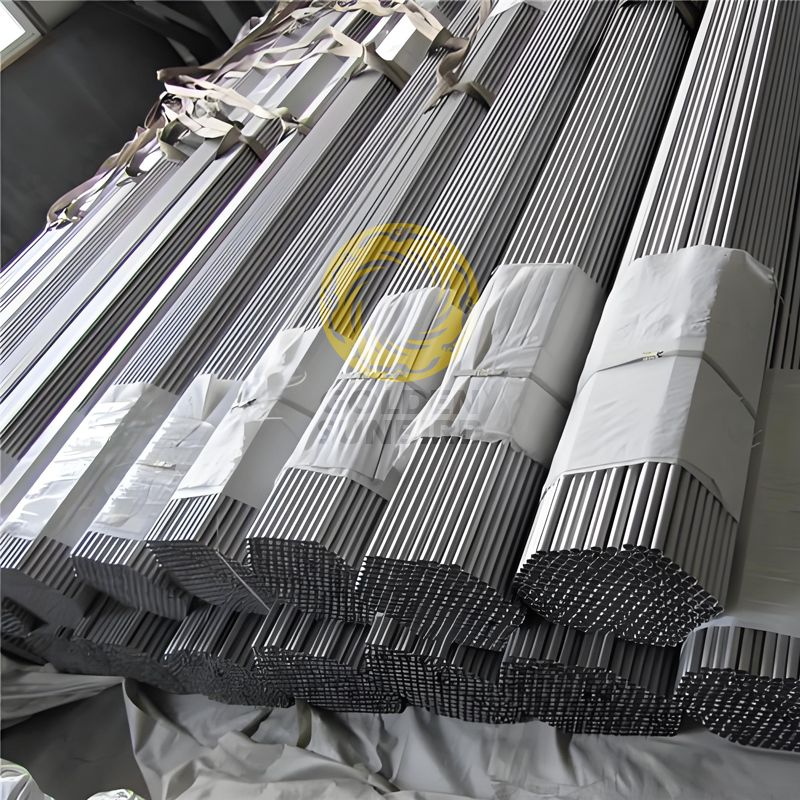

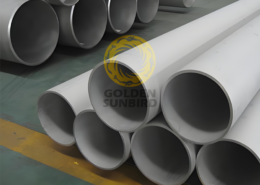

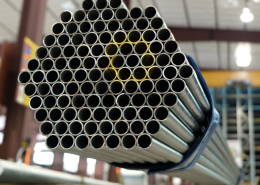

Packing

The tubes are neatly arranged or bundled, lined with PVC bags, and placed inside the wooden crate.

Application

Heat Exchangers: These tubes are extensively used in heat exchangers due to their excellent corrosion resistance, mechanical strength, and ability to withstand high temperatures. They are used in various industries, including chemical, petrochemical, and power generation.

Boilers: These are suitable for boiler applications because they can handle high-pressure steam and water conditions without compromising structural integrity or corroding.

Condensers: These are employed in condensers because they can effectively conduct heat while resisting corrosion from various fluids. This makes them ideal for power plants, refrigeration, and HVAC systems.

Superheaters: These are used in superheaters to improve the thermal efficiency of steam turbines by increasing the temperature of the steam produced. The tubes must endure high temperatures and pressures, making ASTM A249 an appropriate choice.

Feedwater Heaters: In power plants, ASTM A249 tubes are used in feedwater heaters to improve the efficiency of the steam cycle by preheating the water before it enters the boiler.

Evaporators: These are suitable for evaporator applications where the tubes facilitate the phase change of a liquid into a vapor. They are often used in desalination plants, refrigeration, and air conditioning systems.

Specific Industries

Chemical Processing: The tubes resist various chemicals and withstand harsh environments, making them ideal for chemical processing equipment.

Petrochemical Industry: Used in refineries and petrochemical plants due to their ability to resist corrosive materials and high temperatures.

Power Generation: Essential in power generation equipment, particularly in nuclear, fossil fuel, and solar power plants, for handling high-temperature and high-pressure steam.

Food and Beverage Industry: The tubes’ sanitary and corrosion-resistant properties make them suitable for food processing and beverage production equipment.

Pharmaceutical Industry: Employed in pharmaceutical manufacturing processes where corrosion resistance, cleanliness, and material integrity are crucial.