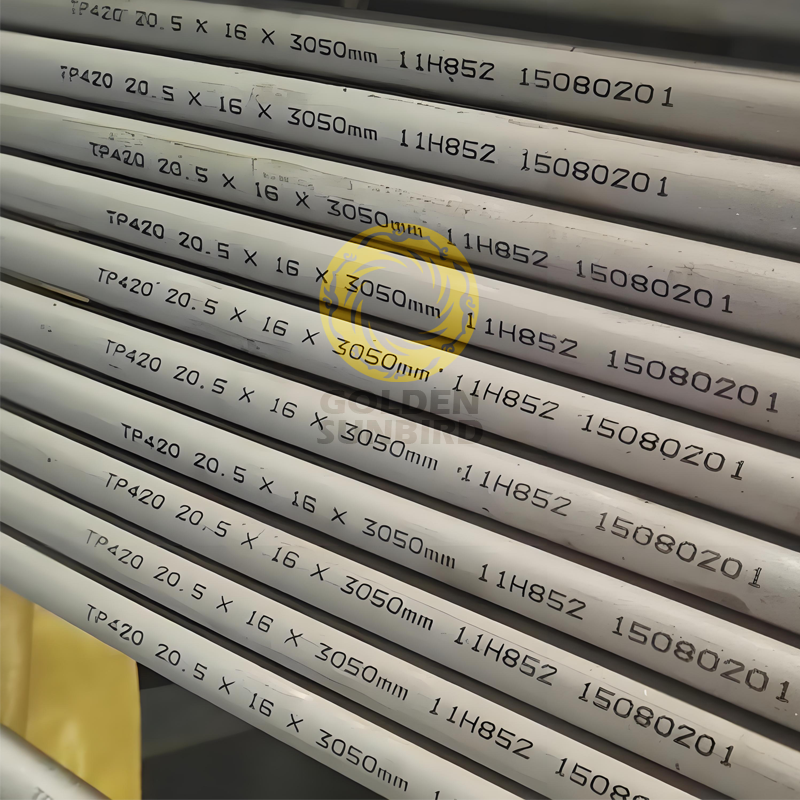

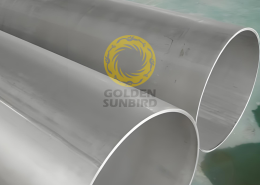

ASTM A268 Ferritic and Martensitic Stainless Steel Tubing

- Grade: TP405, TP410, TP429, TP430, TP443, TP446-1, TP446-2, TP409, TP439, TP430Ti, TP468

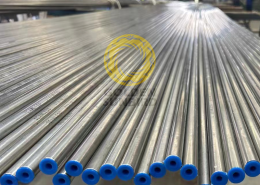

- Tube OD: 4-127mm

- Tube WT: 0.4-12.7mm

- Length: 1000-12000mm

- Type: Seamless & Welded

Features

ASTM A268 Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service

Chemical Composition (wt.%)

| Element | TP405 | TP410 | TP429 | TP430 | TP443 | TP446-1 | TP446-2 | TP409 | TP439 | TP430Ti | TP468 |

| C, max | 0.08 | 0.15 | 0.12 | 0.12 | 0.2 | 0.2 | 0.12 | 0.08 | 0.07 | 0.03 | 0.03 |

| Mn, max | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.50 | 1.50 | 1.00 | 1.00 | 1.00 | 1.00 |

| P, max | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.045 | 0.04 | 0.04 | 0.04 |

| S, max | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.045 | 0.03 | 0.03 | 0.03 |

| Si, max | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Ni | 0.50 max | – | – | – | 0.75 max | 0.75 max | 0.50 max | 0.80 max | 0.50 max | – | 0.5 |

| Cr | 11.5-14.5 | 11.5-13.5 | 14.0-16.0 | 16.0-18.0 | 18.0-23.0 | 23.0-27.0 | 23.0-27.0 | 10.5-11.7 | 17.0-19.0 | 17.0-19.0 | 18.00-20.00 |

| Mo | – | – | – | – | – | – | – | – | – | – | 0.2-1.2 |

| Al | 0.10-0.30 | – | – | – | – | – | – | – | – | – | – |

| Cu | – | – | – | – | 0.90-1.25 | – | – | – | – | – | – |

| N | – | – | – | – | – | – | 0.25 | – | 0.04 | – | 0.03 |

| Ti | – | – | – | – | – | – | – | – | 0.20 + 4(C+N) min | 0.20-1.00 | – |

Mechanical Properties

| Property | TP405 | TP410 | TP429 | TP430 | TP443 | TP446-1 | TP446-2 | TP409 | TP439 | TP430Ti | TP468 |

| Tensile strength, min, ksi [MPa] | 60 [415] | 60 [415] | 60 [415] | 60 [415] | 70 [485] | 70 [485] | 65 [450] | 55 [380] | 60 [415] | 60 [415] | 60 [415] |

| Yield strength, min, ksi [MPa] | 30 [205] | 30 [205] | 35 [240] | 35 [240] | 40 [275] | 40 [275] | 40 [275] | 25 [170] | 30 [205] | 35 [240] | 30 [205] |

| Elongation in 2 in. or 50 mm, min, % | 20 | 20 | 20 | 20 | 20 | 18 | 20 | 20 | 20 | 20 | 22 |

| Brinell Hardness, max | 207 | 207 | 190 | 190 | 207 | 207 | 207 | 207 | 190 | 190 | 207 |

| Rockwell Hardness, B Scale, max | 95 | 95 | 90 | 90 | 95 | 95 | 95 | 95 | 90 | 90 | 95 |

Technical Specifications

| Specification | Value |

| Standard | ASTM A268/A268M Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service |

| Grade | TP405, TP410, TP429, TP430, TP443, TP446-1, TP446-2, TP409, TP439, TP430Ti, TP468 |

| Manufacturing Process | Hot Finished, Cold Finished, Welded |

| Seam Type | Seamless, Welded |

| Dimension | Tube OD: 4-127mm Tube WT: 0.4-12.7mm |

| Length | 1000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tension tests, Flaring tests, Hydrostatic tests, Air underwater pressure tests, Nondestructive electric tests |

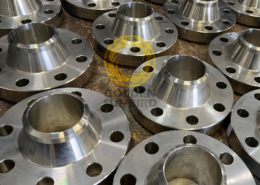

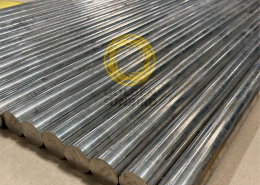

Packing

The tubes are neatly arranged or bundled, lined with PVC bags, and placed inside the wooden crate.

Application

TP405 Applications: TP405 is used in environments requiring moderate corrosion resistance and good formability. Typical applications include:

Exhaust systems, Agricultural equipment, Heat exchangers, Petrochemical industry

TP410 Applications: TP410 is valued for its high mechanical properties and moderate corrosion resistance. It is commonly used in:

Cutlery, Steam and gas turbine blades, Petroleum fractionating equipment, Bolts and fasteners

TP429 Applications: Known for its resistance to high-temperature oxidation and exhaust gas, TP429 is used in:

Automotive exhaust systems, Heat exchangers, Furnace components, Chemical processing equipment

TP430 Applications: TP430 is widely utilized for its good corrosion resistance and formability. Common uses include:

Automotive trim and molding, Appliance components, Architectural applications, Nitric acid plant equipment

TP443 Applications: TP443 is employed in environments where high resistance to corrosion, especially against chlorides and sulfuric acids, is needed. Typical applications are:

Chemical processing equipment, Heat exchangers, Pulp and paper industry, Desalination plants

TP446-1 Applications: TP446-1 is designed for high-temperature applications where oxidation and scaling resistance are crucial. Typical uses include:

Furnace parts, Heat exchangers, Industrial heating systems, Kilns and burners

TP446-2 Applications: Similar to TP446-1 but with enhanced properties for more severe conditions, TP446-2 is used in:

High-temperature furnace components, Burners, Heat exchangers, Incinerators

TP409 Applications: TP409 is commonly used in automotive exhaust systems due to its good high-temperature strength and corrosion resistance. Other applications include:

Catalytic converters, Mufflers, Agricultural equipment, Structural parts

TP439 Applications: TP439 is noted for its good weldability and formability, making it suitable for:

Automotive exhaust systems, Hot water tanks, Air pollution control equipment, Heat exchangers

TP430Ti Applications: TP430Ti, with added titanium to prevent intergranular corrosion, is used in:

Automotive exhaust systems, Kitchenware, Industrial piping, Heat exchangers

TP468 Applications: TP468 is ideal for highly corrosive environments and high-temperature applications, such as:

Chemical processing equipment, Power generation, Heat exchangers, Pulp and paper industry