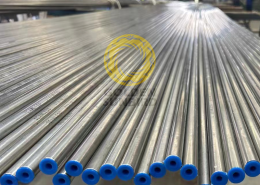

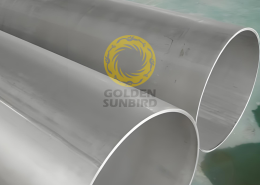

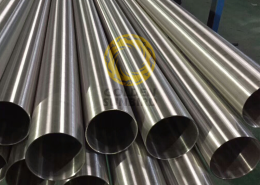

ASTM B514 Welded Incoloy 800/800H/800HT Alloy Pipe

- Welded Nickel-Iron-Chromium Alloy Pipe

- Grade: UNS N08120, UNS N08800 (Incoloy 800), UNS N08810 (Incoloy 800H)

- Outside Diameter (OD) : NPS 1/8″-30″ (10.3-762mm)

- Wall Thickness (WT) : SCH5S, 10S, 40S, 80S (1.65-11.1mm)

Features

ASTM B514 Incoloy 800/800H/800HT Welded Nickel-Iron-Chromium Alloy Pipe

Chemical Composition (wt.%)

| Element | Alloy N08120 (%) | Alloys N08800 and N08810 (%) |

|---|---|---|

| Nickel | 35.0 min, 39.0 max | 30.0 min, 35.0 max |

| Chromium | 23.0 min, 27.0 max | 19.0 min, 23.0 max |

| Iron | Remainder | 39.5 minA |

| Manganese (max) | 1.5 | 1.5 |

| Carbon | 0.02 min, 0.10 max | B |

| Copper (max) | 0.50 | 0.75 |

| Silicon (max) | 1.0 | 1.0 |

| Sulfur (max) | 0.03 | 0.015 |

| Aluminum | 0.40 max | 0.15 min, 0.60 max |

| Titanium | … | 0.15 min, 0.60 max |

| Columbium | 0.20 max | … |

| Molybdenum | 0.4 min, 0.9 max | … |

| Phosphorus (max) | 2.50 | … |

| Tungsten | 0.040 max | … |

| Cobalt (max) | 3.0 | … |

| Nitrogen | 0.15 min, 0.30 max | … |

| Boron (max) | 0.010 | … |

Note:

- A: Iron is determined arithmetically by difference.

- B: For UNS N08800: 0.10 max, For UNS N08810: 0.05 to 0.10.

Mechanical Properties

| Property | UNS N08120 | UNS N08800 | UNS N08810 |

|---|---|---|---|

| Condition (Temper) | Annealed | Annealed | Annealed |

| Tensile Strength (min psi (MPa)) | 90,000 (621) | 75,000 (520) | 65,000 (450) |

| Yield Strength 0.2% Offset (min psi (MPa)) | 40,000 (276) | 30,000 (207) | 25,000 (170) |

| Elongation in 2 in. or 50 mm (min %) | 30 | 30 | 30 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B514 Welded Nickel-Iron-Chromium Alloy Pipe (Incoloy 800/800H/800HT Welded Pipe) |

| Grade | UNS N08120, UNS N08800, and UNS N08810 |

| Manufacturing Process | Automatic welding |

| Seam Type | Welded |

| Tube Size | Outside Diameter (OD) Range: 10.3-762mm, Wall Thickness (WT) Range: SCH5S, 10S, 40S, 80S (1.65-11.1mm) |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

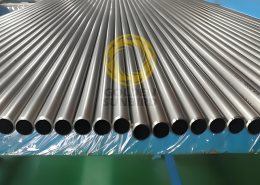

Packing

Bevelled/Plain Ends with Plastic Caps, Packed in plywood boxes or on pallets, bundled or loosely packed.

General Properties of Incoloy 800/800H/800HT:

High-temperature strength: Maintain good mechanical properties at elevated temperatures, suitable for demanding applications.

Oxidation and carburization resistance: Resist oxidation and carburization in high-temperature environments, making them ideal for furnace components and heat exchangers.

Corrosion resistance: Offer good resistance to various corrosive media, including aqueous solutions, oxidizing acids, and some chloride solutions.

Weldability: Can be welded using appropriate techniques while maintaining their properties.

Application

Incoloy 800 (UNS N08800):

General-purpose alloy: Used in a wide range of applications across different industries.

Chemical processing: Heat exchangers, reaction vessels, and piping systems.

Petrochemical industry: Ethylene cracking furnaces, reformer furnaces, and other high-temperature equipment.

Food processing equipment: Components exposed to high temperatures and corrosive food products.

Incoloy 800H (UNS N08810):

Enhanced creep-rupture strength: Designed for applications requiring superior creep resistance at high temperatures.

Power generation: Superheater and reheater tubing in power plants, boiler components.

Petrochemical industry: Ethylene cracking furnaces and other high-temperature applications.

Incoloy 800HT (UNS N08811):

Highest creep and rupture strength: Suitable for the most demanding high-temperature applications.

Petrochemical industry: Ethylene cracking furnaces, reformer tubes, and other high-temperature equipment.

Industrial heating equipment: Components in furnaces and heating elements.