ASTM B517 Welded Inconel 600 Alloy Pipe

- Welded Nickel-Chromium-Iron-Alloy Pipe

- Grade: UNS N06600 (Inconel 600), UNS N06603, UNS N06025, UNS N06045

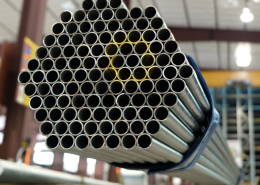

- Outside Diameter (OD): NPS 3/8″ -36″ (10.3-914.4mm)

- Wall Thickness (WT): SCH5, SCH10, SCH40, SCH80

Features

ASTM B517 Welded Inconel 600 Nickel-Chromium-Iron-Alloy Pipe

Inconel 600 Welded Pipe Chemical Composition (wt.%)

| Element | N06600 | N06603 | N06025 | N06045 |

|---|---|---|---|---|

| Nickel (Ni) | 72.0 min | Bal | Bal | 45.0 min |

| Chromium (Cr) | 14.0 min | 24.0-26.0 | 24.0-26.0 | 26.0-29.0 |

| Iron (Fe) | 17.0 max | 8.0-11.0 | 8.0-11.0 | 21.0-25.0 |

| Manganese (Mn) | 1.0 max | 0.15 max | 0.15-0.25 | 1.0 max |

| Carbon (C) | 0.15 max | 20.0-40.0 | 0.15 max | 0.05-0.12 |

| Copper (Cu) | 0.5 max | 0.50 max | 0.10 max | 0.3 max |

| Silicon (Si) | 0.5 max | 0.50 max | 0.5 max | 2.5-3.0 |

| Sulfur (S) | 0.015 max | 0.010 max | 0.010 max | 0.010 max |

| Aluminum (Al) | – | 2.4-3.0 | 1.8-2.4 | – |

| Titanium (Ti) | – | 0.01-0.25 | 0.1-0.2 | – |

| Phosphorus (P) | – | 0.020 max | 0.02 max | 0.02 max |

| Zirconium (Zr) | – | 0.01-0.40 | 0.01-0.10 | – |

| Yttrium (Y) | – | 0.01-0.15 | 0.05-0.12 | – |

| Cerium (Ce) | – | – | – | 0.03-0.09 |

- “Bal” stands for Balance.

- Nickel is determined arithmetically by difference.

Inconel 600 Welded Pipe Mechanical Property Requirements

| Alloy | Tensile Strength min (psi [MPa]) | Yield Strength 0.2 % Offset min (psi [MPa]) | Elongation in 2 in. or 50 mm min (%) |

| N06600 | 80,000 (550) | 35,000 (240) | 30 |

| N06603 | 94,000 (650) | 43,000 (300) | 25 |

| N06025 | 98,000 (680) | 39,000 (270) | 30 |

| N06045 | 90,000 (620) | 35,000 (240) | 30 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B517 Welded Nickel-Chromium-Iron-Alloy Pipe |

| Grade | UNS N06600 (Inconel 600, Alloy 600), UNS N06603, UNS N06025 (Alloy 602CA, EN 2.4633), UNS N06045 |

| Seam Type | Welded |

| Pipe Size | Outside Diameter (OD): NPS 3/8″ -36″ (10.3-914.4mm), Wall Thickness (WT): SCH5, SCH10, SCH40, SCH80 |

| Length | 6000-12000mm |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Flange test, Nondestructive testing (NDT) |

Packing

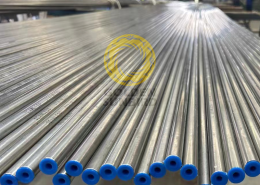

Small Diameter Pipes and Tubes:

End treatment: Beveled or plain ends are capped or plugged with plastic protectors.

Bundling: Smaller diameter pipes and tubes are grouped in bundles.

Protection: Bundles are then covered with seaworthy bags to protect against moisture and damage during transport.

Alternative packaging: Small-diameter pipes can also be loosely packed in plywood boxes instead of bundled in bags for specific needs or handling requirements.

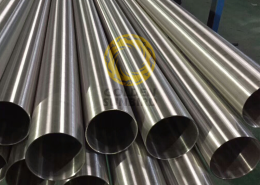

Large Diameter Pipes:

End treatment: Similar to small diameters, beveled or plain ends are likely capped or plugged.

Loose packing: Larger diameter pipes are individually packed and not bundled due to their size and weight.

Protection: Each pipe is covered with a seaworthy bag to protect it against the elements and potential damage during shipping.

Application

UNS N06600 (Alloy 600):

Properties: Excellent resistance to general corrosion, stress corrosion cracking, and oxidation at high temperatures.

Chemical processing: Heat exchangers, reactors, and piping systems handling corrosive chemicals.

Nuclear power plants: Steam generator tubing and other components require corrosion resistance and high-temperature strength.

Heat-treating equipment: Furnace components and heat-treating baskets.

Food processing equipment: Components exposed to high temperatures and corrosive food products.

UNS N06025 (Alloy 603CA):

Properties: Exceptional resistance to various corrosive environments, including seawater, acids, alkalis, and oxidizing/reducing conditions.

Chemical processing: Handling highly corrosive chemicals, including sulfuric acid, hydrochloric acid, and seawater.

Marine and offshore applications: Piping systems, seawater equipment, and desalination plants.

Pollution control equipment: Components in FGD systems and wastewater treatment plants.

Aerospace and gas turbines: Components requiring high strength and corrosion resistance at elevated temperatures.