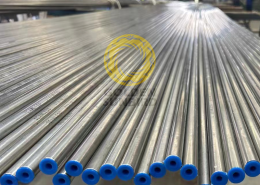

ASTM B622 Seamless Hastelloy C22 & C276 Alloy Pipe and Tube

- Grade: UNS N10001, UNS N10655, UNS N10675, UNS N10276, UNS N06022, UNS N06455, UNS N06200, UNS N06210, UNS R30556, UNS R20033

- Pipe Outside Diameter (OD): NPS 1/4″ -3″, Wall Thickness (WT): SCH10, SCH40, SCH80

- Tube Outside Diameter (OD): 13.72 -88.9mm, Wall Thickness (WT): 1.65-7.62mm

Features

ASTM B622 Seamless Hastelloy C22 & C276 Nickel and Nickel-Cobalt Alloy Pipe & Tube

Hastelloy C22 & C276 Pipe & Tube Chemical Composition (wt.%)

| UNS No. | (Ni) (%) | (Cr) (%) | (Mo) (%) | (Fe) (%) | (Co) (%) | (W) (%) | (C) (%) | (Mn) (%) | (Si) (%) | (P) (%) | (S) (%) |

| N10001 | 63.0 min | 28.5-31.5 | 5.0-7.0 | 1.0 max | 2.5 max | 1.5-3.0 | 0.03 max | 1.0 max | 0.08 max | 0.04 max | 0.03 max |

| N10655 | 65.0 min | 14.0-18.0 | 15.0-17.0 | 3.0 max | – | 3.0-4.0 | 0.010 max | 1.0 max | 0.08 max | 0.040 max | 0.030 max |

| N10675 | 65.0 min | – | 27.0 min | 3.0 max | 2.5 max | 3.0 max | 0.010 max | 3.0 max | 0.10 max | 0.020 max | 0.010 max |

| N10276 | 57.0 min | 14.5-16.5 | 15.0-17.0 | 4.0-7.0 | 2.5 max | 3.0 max | 0.010 max | 1.0 max | 0.08 max | 0.040 max | 0.030 max |

| N06022 | 58.0 min | 20.0-22.5 | 12.5-14.5 | 2.0 max | 2.5 max | – | 0.010 max | 0.50 max | 0.08 max | 0.020 max | 0.020 max |

| N06455 | 65.0 min | 14.0-18.0 | 15.0-17.0 | 3.0 max | – | 3.0-4.0 | 0.010 max | 1.0 max | 0.08 max | 0.040 max | 0.030 max |

| N06200 | 55.0 min | 23.0-28.0 | 15.0-17.0 | 3.0 max | 2.5 max | 1.6-2.5 | 0.010 max | 0.50 max | 0.08 max | 0.020 max | 0.020 max |

| N06210 | 67.0 min | – | 4.0-6.0 | 6.0 max | 2.5 max | 1.5 max | 0.020 max | 1.0 max | 0.10 max | 0.015 max | 0.010 max |

| R30556 | 65.0 min | – | 26.0-30.0 | 2.0 max | 2.5 max | 1.0 max | 0.010 max | 1.0 max | 0.10 max | 0.040 max | 0.030 max |

| R20033 | 65.0 min | 2.5 max | – | 3.0 max | 2.5 max | 2.5 max | 0.010 max | 1.0 max | 0.10 max | 0.040 max | 0.030 max |

Hastelloy C22 & C276 Pipe & Tube Mechanical properties

|

Alloy |

Tensile Strength (min, ksi) | Yield Strength (0.2% Offset, min, ksi) | Elongation (in 2 in. or 4D, min, %) |

| UNS N10001 | 100 | 45 | 40 |

| UNS N10665 | 110 | 51 | 40 |

| UNS N10675 | 110 | 51 | 40 |

| UNS N10629 | 110 | 51 | 40 |

| UNS N10624 | 104 | 46 | 40 |

| UNS N10242 | 105 | 45 | 40 |

| UNS N10276 | 100 | 41 | 40 |

| UNS N06022 | 100 | 45 | 45 |

| UNS N06035 | 85 | 35 | 30 |

| UNS N06455 | 100 | 40 | 40 |

| UNS N06007 | 90 | 35 | 35 |

| UNS N06975 | 85 | 32 | 40 |

| UNS N06985 | 90 | 35 | 40 |

| UNS N06030 | 85 | 35 | 30 |

| UNS N06255 | 85 | 32 | 40 |

| UNS N06250 | 90 | 35 | 40 |

| UNS N08320 | 75 | 28 | 35 |

| UNS N08135 | 73 | 31 | 40 |

| UNS N06002 | 100 | 40 | 35 |

| UNS N06060 | 90 | 35 | 40 |

| UNS R30556 | 100 | 45 | 40 |

| UNS N06230 | 110 | 45 | 40 |

| UNS N06058 | 110 | 52 | 40 |

| UNS N06059 | 100 | 45 | 45 |

| UNS N06200 | 100 | 45 | 45 |

| UNS N10362 | 105 | 45 | 40 |

| UNS N08031 | 94 | 40 | 40 |

| UNS N08535 | 73 | 31 | 40 |

| UNS N06686 | 100 | 45 | 45 |

| UNS N12160 | 90 | 35 | 40 |

| UNS R20033 | 109 | 55 | 40 |

| UNS N06210 | 100 | 45 | 45 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B622 Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube |

| Grade | UNS N10001, UNS N10242, UNS N10665, UNS N12160, UNS N10675, UNS N10276, UNS N06455, UNS N06007, UNS N08320, UNS N06975, UNS N06002, UNS N06985, UNS N06022, UNS N06035, UNS N08135, UNS N06255, UNS N06058, UNS N06059, UNS N06200, UNS N06030, UNS N08031, UNS R30556, UNS N08535, UNS N06250, UNS N06060, UNS N06230, UNS N06686, UNS N10629, UNS N06210, UNS N10624, and UNS R20033 |

| Manufacturing Process | cold-finished of hot-finished |

| Seam Type | Seamless |

| Pipe Size | Outside Diameter (OD) Range: NPS 1/4″ -3″, Wall Thickness (WT) Range: SCH10, SCH40, SCH80 |

| Tube Size | Outside Diameter (OD) Range: 13.72 -88.9mm, Wall Thickness (WT) Range: 1.65-7.62mm |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

Packing

Small Diameter Pipes and Tubes:

End treatment: Beveled or plain ends are capped or plugged with plastic protectors.

Bundling: Smaller diameter pipes and tubes are grouped in bundles.

Protection: Bundles are then covered with seaworthy bags for protection against moisture and damage during transport.

Alternative packaging: For specific needs or handling requirements, small-diameter pipes can also be loosely packed in plywood boxes instead of bundled in bags.

Large Diameter Pipes:

End treatment: Similar to small diameters, bevelled or plain ends are likely capped or plugged.

Loose packing: Larger diameter pipes are individually packed and not bundled due to their size and weight.

Protection: Each pipe is covered with a seaworthy bag for protection against the elements and potential damage during shipping.

Application

Nickel-Molybdenum Alloys:

UNS N10001 (Hastelloy B-2): Excellent resistance to reducing environments, particularly hydrochloric acid at all concentrations and temperatures. Used in chemical processing, pharmaceuticals, and pickling operations.

UNS N10665 (Hastelloy B-3): Similar to B-2 with improved thermal stability and fabrication characteristics. Ideal for chemical processing involving hydrochloric acid and other reducing media.

Nickel-Chromium-Molybdenum Alloys:

UNS N10276 (Hastelloy C-276): Versatile alloy with outstanding resistance to a wide range of corrosive environments, including oxidizing and reducing acids, chlorides, and sour gas. Widely used in chemical processing, pollution control, oil & gas, and pharmaceutical industries.

UNS N06022 (Hastelloy C-22): Superior resistance to localized corrosion (pitting and crevice corrosion) in chloride environments and oxidizing acids. Ideal for chemical processing, pulp & paper, and waste treatment applications.

UNS N06455 (Hastelloy C-4): Enhanced resistance to stress corrosion cracking and pitting in chloride solutions. Suitable for seawater applications and chemical processing equipment.

UNS N06200 (Hastelloy C-2000): Offers a balance of properties, resisting both oxidizing and reducing environments. Used in chemical processing, pharmaceutical, and various corrosive applications.

Nickel-Chromium-Iron Alloys:

UNS N06600 (Inconel 600): Excellent resistance to general corrosion, stress corrosion cracking, and oxidation at high temperatures. Used in chemical processing, nuclear power, heat treating, and food processing equipment.

UNS N06210 (Hastelloy G-30): Enhanced resistance to stress corrosion cracking in chloride solutions and good resistance to sulfuric acid. Suitable for chemical processing, seawater applications, and pollution control equipment.

Nickel-Cobalt Alloys:

UNS R30556 (MP35N): High-strength alloy with excellent corrosion resistance and fatigue strength. Used in medical devices, aerospace components, and marine applications.

UNS R20033 (Alloy 20Cb-3): Similar corrosion resistance to Alloy 20 with improved resistance to intergranular corrosion. Used in chemical processing, pulp & paper, and food processing equipment.