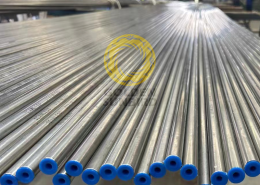

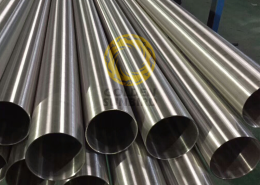

ASTM B675 Welded UNS N08367 Alloy Pipe

- Grade: UNS N08367 (AL-6XN, X1NiCrMoCuN25-20-7, EN 1.4529)

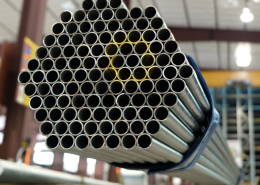

- Outside Diameter (OD): NPS 1/8″ -30″ (10.3-762mm)

- Wall Thickness (WT): SCH 5S, 10S, 40S, 80S, 160S

Features

ASTM B675 Iron-Nickel-Chromium-Molybdenum Alloy Welded Pipe

Chemical Composition (wt.%)

| Element | Composition Limits (%) |

|---|---|

| Carbon (C) | 0.030 max |

| Manganese (Mn) | 2.00 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 20.00–22.00 |

| Nickel (Ni) | 23.50–25.50 |

| Molybdenum (Mo) | 6.00–7.00 |

| Nitrogen (N) | 0.18–0.25 |

| Iron (Fe) | Balance |

| Copper (Cu) | 0.75 max |

Mechanical Properties

| Gage (thickness) | Tensile Strength (min ksi [MPa]) | Yield Strength (0.2% Offset) (min ksi [MPa]) | Elongation in 2 in. or 50 mm (or 4D) min (%) |

| # 3⁄16 and over | 100 (690) | 45 (310) | 30 |

| Over 3⁄16 | 95 (655) | 45 (310) | 30 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B675 UNS N08367 Welded Pipe |

| Grade | UNS N08367 (AL-6XN, X1NiCrMoCuN25-20-7, EN 1.4529) |

| Seam Type | Welded |

| Pipe Size | Outside Diameter (OD): NPS 1/8″ -30″ (10.3-762mm) Wall Thickness (WT): SCH 5S, 10S, 40S, 80S, 160S |

| Length | 6000-12000mm |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Flaring test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

Key Features

Outstanding resistance to localized corrosion: High molybdenum and nitrogen content provide excellent resistance to pitting and crevice corrosion in chloride solutions.

Good resistance to stress corrosion cracking: Offers reliable performance in environments susceptible to stress corrosion cracking.

High strength and ductility: Maintains good mechanical properties and formability.

Weldability: Can be welded using appropriate techniques while preserving its corrosion resistance and mechanical properties.

Packing

Pipes with plain or beveled ends, equipped with caps or bevel protectors. Small diameter pipes are packed in wooden crates or wrapped in woven bags and hexagonally bundled. Large-diameter pipes are loosely packed and wrapped in woven bags.

Application

UNS N08367, often referred to as AL-6XN®, is a superaustenitic stainless steel within the ASTM B675 specification. It stands out for its exceptional resistance to chloride-induced localized corrosion, including pitting and crevice corrosion, making it ideal for demanding applications in seawater and other chloride-rich environments.

Seawater piping systems: Excellent resistance to seawater corrosion makes it suitable for piping systems on offshore platforms, desalination plants, and seawater cooling systems.

Subsea equipment: Used for components exposed to seawater and high pressures, such as umbilicals, risers, and subsea structures.

Shipbuilding: Applications in seawater ballast systems, fire-fighting systems, and other piping systems exposed to seawater.

Heat exchangers and condensers: Handling chloride-containing fluids and process streams where resistance to localized corrosion is critical.

Process piping and equipment: Used in chemical processing applications involving chlorides, acids, and other corrosive media.

Pulp and paper industry: Equipment exposed to bleaching chemicals and other chloride-containing solutions.

Food processing equipment: Suitable for handling brines and other chloride-rich food products.

Wastewater treatment: Handles chloride-containing wastewater and chemical treatment processes.