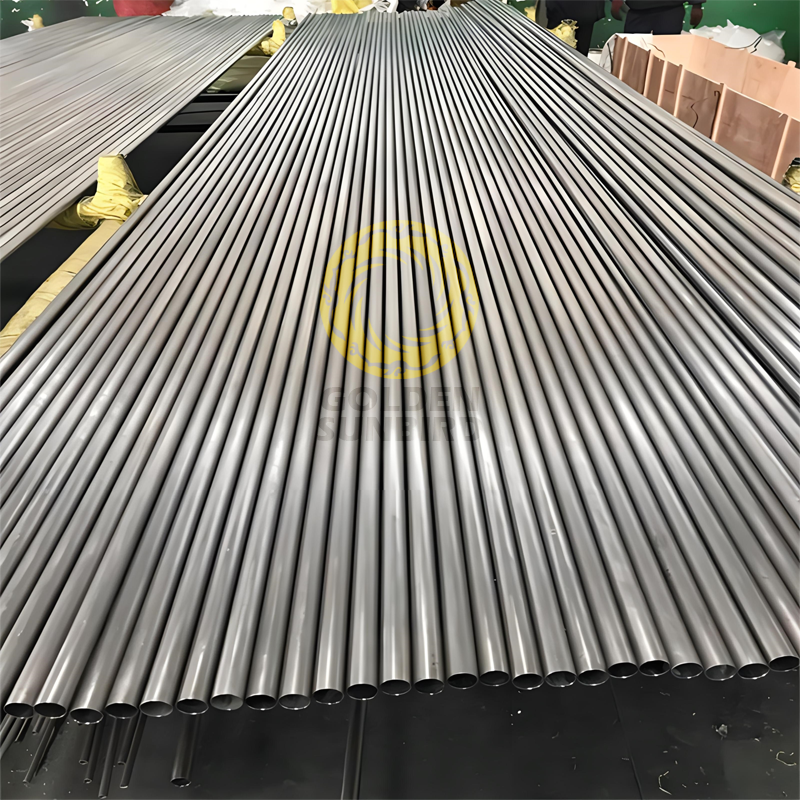

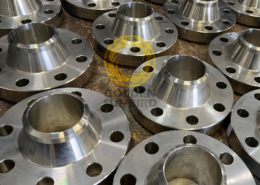

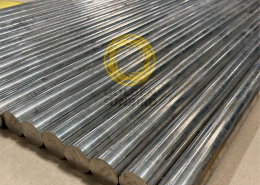

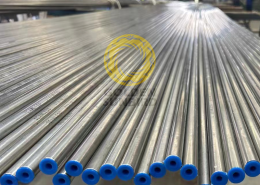

ASTM B690 Seamless UNS N08366, N08367 Alloy Pipe and Tube

- Grade: UNS N08366, UNS N08367 (AL-6XN, X1NiCrMoCuN25-20-7, EN 1.4529)

- Type: Iron-Nickel-Chromium-Molybdenum Alloys

- Pipe OD: NPS 1/4″ -6″ (13.7-168.3mm), Pipe WT: SCH 5, 10, 40, 80

- Tube OD: 6.4-152.4mm, Tube WT: 1.65-8.56mm

Features

ASTM B690 UNS N08366 & N08367 Seamless Pipe and Tube

UNS N08366 & N08367 Nickel Seamless Pipe Chemical Composition (wt.%)

| Element | Composition Limits, % (N08366) | Composition Limits, % (N08367) |

|---|---|---|

| Carbon | 0.035 max | 0.030 max |

| Manganese | 2.00 max | 2.00 max |

| Silicon | 1.00 max | 1.00 max |

| Phosphorus | 0.040 max | 0.040 max |

| Sulfur | 0.030 max | 0.030 max |

| Chromium | 20.00 to 22.00 | 20.00 to 22.00 |

| Nickel | 23.50 to 25.50 | 23.50 to 25.50 |

| Molybdenum | 6.00 to 7.00 | 6.00 to 7.00 |

| Nitrogen | … | 0.18 to 0.25 |

| Iron | remainder | remainder |

| Copper | 0.75 max | 0.75 max |

UNS N08366 (Annealed) and UNS N08367 Mechanical Properties

| Property | Specification (ksi [MPa]) |

|---|---|

| Tensile strength | 75 [517] minimum |

| Yield strength (0.2% offset) | 30 [206] minimum |

| Elongation (in 2 in. or 50 mm) | 30% minimum |

Please note, the values provided are minimum requirements; actual material properties can vary based on specific material processing and condition.

Technical Specifications

| Specification | Value |

| Standard | ASTM B690 Iron-Nickel-Chromium-Molybdenum Alloy Seamless Pipe and Tube |

| Grade | UNS N08366, UNS N08367 (AL-6XN, X1NiCrMoCuN25-20-7, EN 1.4529) |

| Manufacturing Process | cold-finished of hot-finished |

| Seam Type | Seamless |

| Pipe Size | Outside Diameter (OD): NPS 1/4″ -6″, Wall Thickness (WT): SCH5, SCH10, SCH40, SCH80 |

| Tube Size | Outside Diameter (OD): 6.4 -152.4mm, Wall Thickness (WT): 1.65-8.56mm |

| Length | 6000-12000mm |

| Delivery Condition | Annealed |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDE Test), Intergranular corrosion test, Metallographic examination |

Packing

Pipes with plain or bevelled ends, equipped with caps or bevel protectors. Small diameter pipes are packed in wooden crates or wrapped in woven bags and hexagonally bundled. Large-diameter pipes are loosely packed and wrapped in woven bags.

Application

Heat exchangers and condensers: Used in processes involving seawater or brackish water cooling due to their resistance to chloride-induced corrosion.

Process piping and equipment: Handling corrosive chemicals, particularly those containing chlorides, at high temperatures and pressures.

Offshore platforms and subsea equipment: Their resistance to seawater and chloride-induced corrosion makes them suitable for offshore applications.

Sour gas wells: Used for downhole tubing and equipment exposed to H2S and CO2 environments.

Evaporators and piping systems: Excellent resistance to seawater corrosion and pitting makes them ideal for desalination applications.

Handling of corrosive wastewater and sludge: Provides reliable performance in harsh environments containing chlorides and other contaminants.