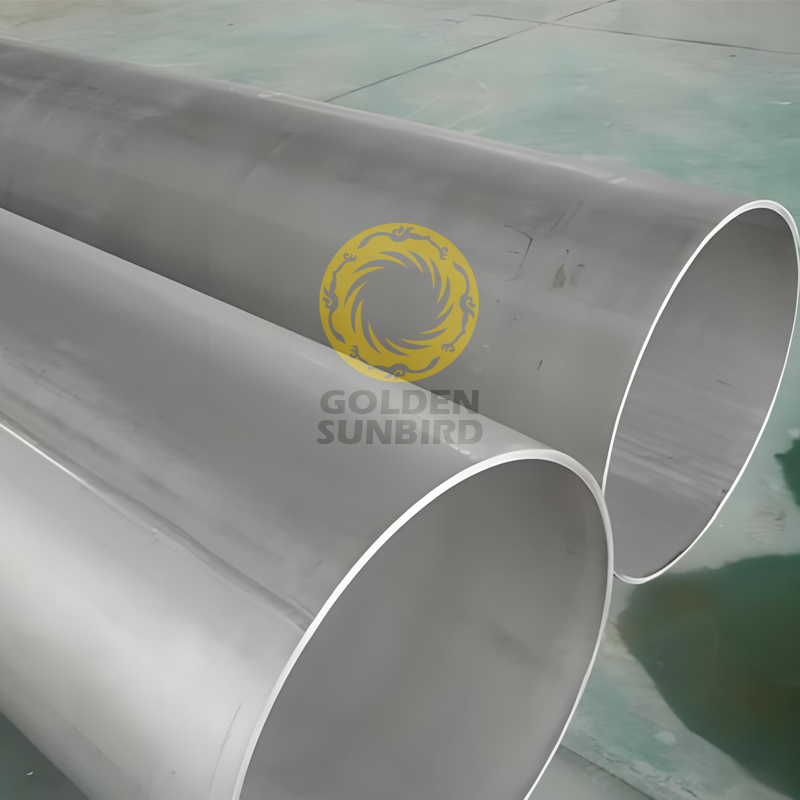

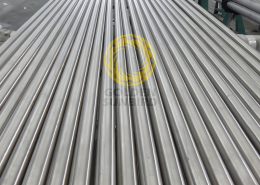

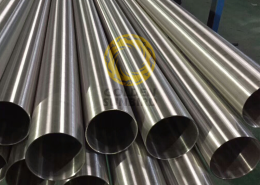

ASTM B705 Welded UNS N06625, N08825 Alloy Pipe

- Grade: UNS N06625 UNS N06219 UNS N08825

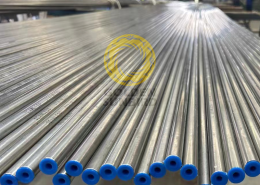

- Outside Diameter (OD): NPS 1/8″ -30″ (10.3-762mm)

- Wall Thickness (WT): SCH 5S, 10S, 40S, 80S

Features

ASTM B705 Welded UNS N06625 & N08825 Nickel Pipe

UNS N06625 & N08825 nickel pipe Chemical Composition (wt.%)

| Element | UNS N06625 Limits (%) | UNS N06219 Limits (%) | UNS N08825 Limits (%) |

| Ni | 58.0 min* | Bal | 38.0–46.0 |

| Cr | 20.0–23.0 | 18.0-22.0 | 19.5–23.5 |

| Fe | 5.0 max | 2.0-4.0 | 22.0 min* |

| Mo | 8.0–10.0 | 7.0-9.0 | 2.5-3.5 |

| Cb + Ta | 3.15–4.15 | – | – |

| C | 0.10 max | 0.05 max | 0.05 max |

| Mn | 0.50 max | 0.50 max | 1.0 max |

| Si | 0.5 max | 0.70-1.10 | 0.5 max |

| P | 0.015 max | 0.020 max | – |

| S | 0.015 max | 0.010 max | 0.03 max |

| Al | 0.4 max | 0.50 max | 0.2 max |

| Ti | 0.40 max | 0.50 max | 0.6–1.2 |

| Co | 1.0 max (if determined) | 1.0 max | – |

| Cu | – | 0.50 max | 1.5–3.0 |

UNS N06625 & N08825 nickel pipe Mechanical Properties

| Alloy | Grade | Tensile Strength min (psi / MPa) | Yield Strength 0.2% Offset min (psi / MPa) | Elongation in 2 in. or 50 mm min (%) |

| UNS N06625 | 1 (annealed) | 120,000 / 827 | 60,000 / 414 | 30 |

| UNS N06625 | 2 (solution annealed) | 100,000 / 690 | 40,000 / 276 | 30 |

| UNS N06219 | – | 96,000 / 660 | 39,000 / 270 | 30 |

| UNS N08825 | – | 85,000 / 586 | 35,000 / 240 | 30 |

Technical Specifications

| Specification | Value |

| Standard | ASTM B705 Nickel-Alloy (UNS N06625, N06219 and N08825) Welded Pipe |

| Grade | UNS N06625 (EN 2.4856, NiCr22Mo9Nb, Alloy 625), UNS N06219, UNS N08825 (EN 2.4858, Alloy 825) |

| Manufacturing Process | Automatic welding |

| Seam Type | Welded |

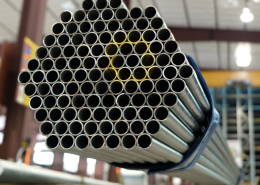

| Welded Pipe SPS Diameters | Outside Diameter (OD) Range: NPS 1/8″-30″ (10.3-762mm), Wall Thickness (WT) Range: SCH5, SCH10, SCH40, SCH80 (1.24-12.7mm) |

| Length | 6000-12000mm |

| Delivery Condition | UNS N06625 Grade 1 Annealed, Grade 2 Solution Annealed; UNS N06219, UNS N08825 |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Test | Chemical analysis, Tensile test, Flattening test, Expansion test, Hydrostatic test, Nondestructive testing (NDT), Intergranular corrosion test, Metallographic examination |

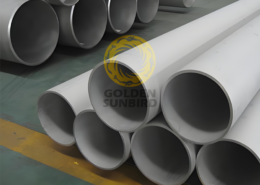

Packing

Pipes with plain or bevelled ends, equipped with caps or bevel protectors. Small diameter pipes are packed in wooden crates or wrapped in woven bags and hexagonally bundled. Large-diameter pipes are loosely packed and wrapped in woven bags.

Application

UNS N06625 (Alloy 625) Applications:

Chemical Processing Equipment: Handling highly corrosive chemicals and intermediates.

Aerospace & High-Temperature Systems: Components in jet engines, exhaust systems, and heat exchangers due to their ability to withstand extreme temperatures.

Oil and Gas Production: Well casings, pipelines for harsh downhole environments with high temperatures and potential for H2S (sour gas) corrosion.

Seawater Applications: Desalination plants, and offshore structures due to its exceptional resistance to saltwater corrosion.

UNS N08825 (Incoloy 825) Applications:

Chemical Processing Plants: For handling a variety of corrosive chemicals.

Petrochemical Plants: Conveying chemicals and resisting harsh environments encountered in petrochemical refining.

Heat Exchangers: Can handle high temperatures and potential corrosive fluids.

Seawater Applications: Desalination plants, and offshore structures due to its good resistance to saltwater corrosion, though not quite matching N06625.