Golden Sunbird Metals is a professional nickel alloy supplier in China. We offer high-quality nickel alloy products at wholesale prices, and our experience in customized solutions makes us an ideal choice for professionals. Our Incoloy 800H/800HT, Inconel 600/617/625/718, Monel 400, Nickel 200/201, Hastelloy C22/C276/G30, and Sanicro 28 products exhibit exceptional performance and reliability in High-Temperature Strength, Weldability and Formability, Corrosion and Oxidation Resistance in Acids (Sulfuric acid, Hydrochloric acid, Nitric acid, Phosphoric acid, Hydrofluoric acid, Hydrogen fluoride, Fluorine), Alkalis (Caustic Soda NaOH, Caustic Potassium KOH, Lime Ca(OH)2, Ammonia solution NH3·H2O), and Sea Salts (NaCl, MgCl2, Na2SO4, MgSO4) environments. If you want to buy nickel alloy products in bulk, please get in touch with [email protected].

GOLDEN SUNBIRD METALS’ SUPPLY LIST OF NICKEL ALLOY PRODUCTS:

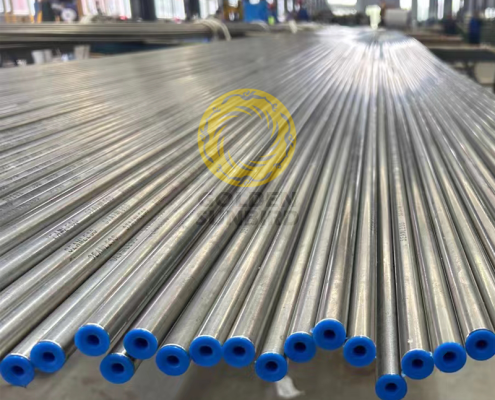

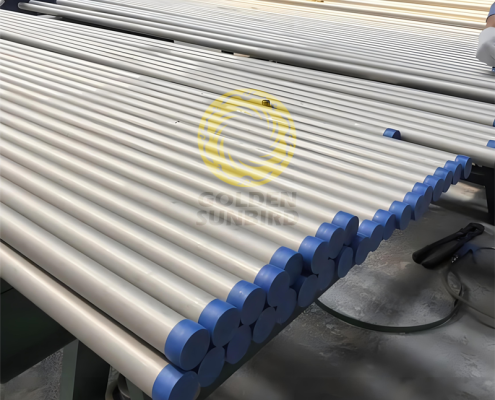

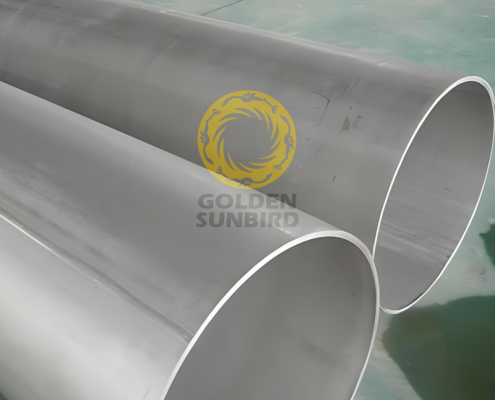

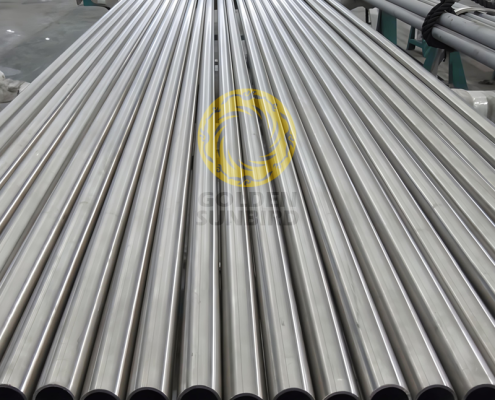

Nickel Alloy Pipe and Tube

Nickel Alloy Pipe and Tube products feature exceptional corrosion resistance and durability, making them ideal for critical applications in chemical processing, aerospace, and oil and gas industries where reliability in harsh conditions is paramount.

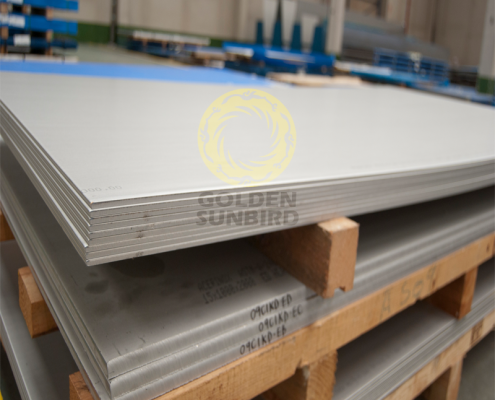

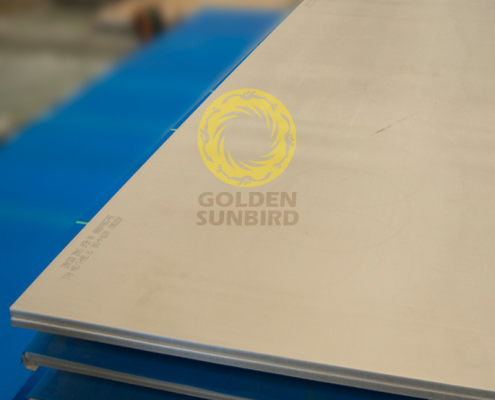

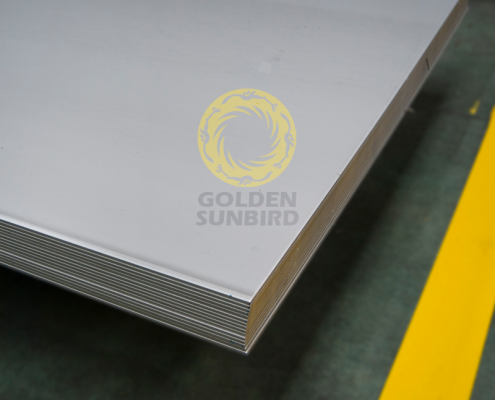

Nickel Alloy Plate and Sheet

Nickel Alloy Plates and sheets offer outstanding strength, resilience, and corrosion resistance. These products are essential for marine and chemical processing applications where durability and performance in demanding environments are crucial.

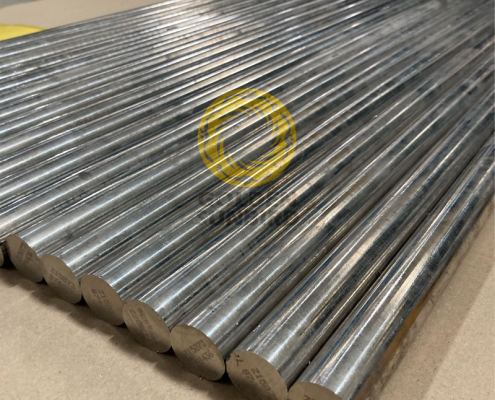

Nickel Alloy Bar

Nickel alloy bars are known for their high tensile strength, excellent ductility, and superior corrosion resistance. They are indispensable in the aerospace, automotive, and industrial machinery sectors, where reliability and versatility are critical.

Nickel Alloy Forgings

Nickel Alloy Forgings products provide unparalleled strength, durability, and resistance to extreme temperatures and corrosive environments. They are indispensable in power generation, petrochemical, and nuclear industries, where reliability and longevity under harsh conditions are vital.

Nickel Alloy Flange

Nickel alloy flanges connect pipes, valves, pumps, and other equipment to form a piping system. They are highly resistant to corrosion and high-temperature environments.

Nickel Alloy Pipe Fittings

These fittings are essential for modifying and managing the flow in piping systems. They provide durability and resistance to harsh conditions, such as high temperatures and corrosive substances.

FAQs

What Are Nickel Alloys?

Nickel alloys are metals made by combining nickel with other elements to enhance its natural properties. The composition and amount of additional elements are adjusted based on the desired characteristics of the final alloy. Common elements mixed with nickel include chromium, iron, copper, and molybdenum. These alloys are engineered to offer superior corrosion resistance, high temperature performance, and strength.

- Nickel alloys are combinations of nickel and other elements.

- They are designed to enhance corrosion resistance, temperature tolerance, and strength.

- Common alloying elements include chromium, iron, and copper.

Why Are Nickel Alloys Important in Industry?

Nickel alloys play a crucial role in various industries due to their robustness and versatility. Their exceptional resistance to corrosion and ability to perform under high temperatures make them indispensable in harsh environments. Industries such as aerospace, chemical processing, and power generation rely on nickel alloys for critical components, including turbine blades, chemical reactors, and heat exchangers.

- Critical for industries facing extreme conditions.

- Used in aerospace, chemical processing, and power generation.

- Ideal for turbine blades, reactors, and heat exchangers due to their durability.

How Are Nickel Alloys Manufactured?

The manufacturing of nickel alloys involves several complex processes, starting with the melting of pure nickel together with other metals to achieve the desired composition. This molten mixture is then cast into ingots or bars, followed by various forms of processing such as rolling, forging, and annealing to improve its mechanical properties and workability. The specific manufacturing process can vary significantly based on the alloy’s intended use and required characteristics.

- Involves melting, casting, and processing to achieve desired properties.

- Manufacturing steps include rolling, forging, and annealing.

- Processes vary based on the alloy’s intended application and required features.

What Are the Types of Nickel Alloys and Their Uses?

Nickel alloys can be broadly categorized into corrosion-resistant, heat-resistant, and high-performance alloys. Corrosion-resistant alloys, such as Inconel, are used in chemical processing equipment. Heat-resistant alloys, such as Hastelloy, are employed in high-temperature environments like gas turbines. High-performance alloys, offering both high strength and corrosion resistance, are utilized in aerospace and marine applications.

- Corrosion-resistant alloys are used in chemical processing.

- Heat-resistant alloys are suitable for high-temperature environments.

- High-performance alloys are used in aerospace and marine applications for their strength and corrosion resistance.

Can Nickel Alloys Be Recycled?

Yes, nickel alloys can be recycled and reused, which adds to their value and sustainability. The recycling process involves collecting and melting down scrap nickel alloy materials, then purifying and reforming them into new products. This process not only conserves natural resources but also reduces energy consumption and environmental impact compared to producing new alloys from raw materials. Recycling is common in industries that use nickel alloys, contributing to a more sustainable use of materials.

- Nickel alloys can be recycled, conserving resources and energy.

- The recycling process involves melting, purifying, and reforming.

- Recycling contributes to the sustainability of nickel alloy usage.

What Are the Environmental Impacts of Nickel Alloy Production?

The production of nickel alloys, like that of many metals, can have significant environmental impacts. These include the energy-intensive nature of mining and processing raw materials, emissions of greenhouse gases, and the potential for pollution of water sources with heavy metals. However, the industry is increasingly adopting more sustainable practices, such as improving energy efficiency, using cleaner energy sources, and implementing stricter waste management and recycling protocols to mitigate these impacts.

- Production is energy-intensive and can lead to emissions and pollution.

- The industry is moving towards more sustainable practices.

- Improvements include better energy efficiency and waste management.

How Does Temperature Affect the Properties of Nickel Alloys?

Nickel alloys are renowned for their ability to retain strength and corrosion resistance at high temperatures, a property that distinguishes them from many other metals. As temperature increases, the strength of many metals decreases, but nickel alloys are designed to maintain or even enhance their mechanical properties under thermal stress. This makes them ideal for use in applications like jet engines, gas turbines, and nuclear reactors, where materials must perform reliably in extreme heat.

- Nickel alloys maintain or enhance properties at high temperatures.

- Ideal for applications subjected to thermal stress.

- Used in jet engines, turbines, and nuclear reactors for their thermal resilience.