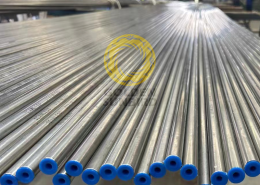

ASTM A312 Stainless Steel Pipes

- Grade: UNS S30600, S30601, S31254, S32053, S32615, S32654, S38815, N08020, N08028, N08029, N08367, N08800, N08810, N08811, N08904, N08925, N08926

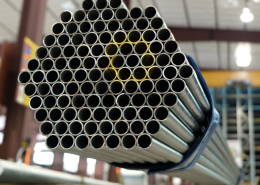

- Pipe OD: NPS 1/8″-48″ (10.3-1219.2mm)

- Pipe WT: SCH 5S, 10S, 40S, 80S, XS, XXS

- Length: 3000-12000mm

- Type: Seamless and Welded

Features

ASTM A312/A312M Seamless, Welded, and Heavily Cold Worked Stainless Steel Pipes

Chemical Composition (wt.%)

| UNS No. | Grade | C(%) | Mn(%) | P (%) | S(%) | Si(%) | Cr(%) | Ni(%) | Mo(%) | Others (%) |

| N08020 | Alloy 20 | 0.07 | 2.00 | 0.045 | 0.035 | 1.00 | 19.0-21.0 | 32.0-38.0 | 2.0-3.0 | – |

| N08028 | Alloy 28 | 0.030 | 2.50 | 0.030 | 0.030 | 1.00 | 26.0-28.0 | 30.0-34.0 | 3.0-4.0 | Cu 0.6-1.4 |

| N08029 | – | 0.020 | 2.00 | 0.025 | 0.015 | 0.60 | 26.0-28.0 | 30.0-34.0 | 4.0-5.0 | Cu 0.6-1.4 |

| N08367 | 6% Mo | 0.030 | 2.00 | 0.040 | 0.030 | 1.00 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | N 0.18-0.25 |

| N08800 | 800 | 0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | – | Al+Ti 0.15-0.60 |

| N08810 | 800H | 0.05-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | – | Al+Ti 0.15-0.60 |

| N08811 | 800HT | 0.06-0.10 | 1.50 | 0.045 | 0.015 | 1.00 | 19.0-23.0 | 30.0-35.0 | – | Al+Ti 0.15-0.60 |

| N08904 | 904L | 0.020 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | Cu 1.0-2.0 |

| N08925 | – | 0.020 | 1.50 | 0.045 | 0.030 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | N 0.1-0.25 |

| N08926 | 6% Mo | 0.020 | 2.00 | 0.030 | 0.010 | 0.50 | 19.0-21.0 | 24.0-26.0 | 6.0-7.0 | N 0.15-0.25 |

| UNS No. | Grade | C(%) | Mn(%) | P(%) | S(%) | Si(%) | Cr(%) | Ni(%) | Mo(%) | Ni(%) | Cu(%) |

| S30600 | 4% Si | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 14.0-16.0 | 1.0-3.0 | 0.10 | – |

| S30601 | 5% Si | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-19.0 | 14.0-16.0 | 1.0-3.0 | 0.10 | – |

| S31254 | 6% Mo, 254SMO | 0.020 | 1.00 | 0.030 | 0.010 | 0.80 | 19.5-20.5 | 17.5-18.5 | 6.0-6.5 | 0.18-0.25 | 0.50-1.00 |

| S32053 | 0.020 | 2.0-4.0 | 0.030 | 0.010 | 0.80 | 23.0-25.0 | 16.0-18.0 | 7.0-8.0 | 0.45-0.55 | – | |

| S32654 | 7% Mo, 654SMO | 0.020 | 2.0-4.0 | 0.030 | 0.010 | 0.50 | 24.0-25.0 | 21.0-23.0 | 7.0-8.0 | 0.40-0.60 | – |

| S32615 | 5% Si | 0.07 | 2.00 | 0.045 | 0.030 | 4.8-6.0 | 16.5-19.5 | 19.0-22.0 | 0.30-1.50 | 1.50-2.50 | |

| S38815 | 6% Si | 0.030 | 2.00 | 0.040 | 0.020 | 5.5-6.5 | 13.0-15.0 | 15.0-17.0 | 0.75-1.50 | 0.75-1.50 |

Technical Specifications

phic examination

| Specification | Value |

| Standard | ASTM A312/A312M Seamless, Welded, and Heavily Cold Worked Stainless Steel Pipes |

| Grade | UNS S30600 (EN 1.4361), S30601, S31254 (254 SMO, F44, X1CrNiMoCuN20-18-7, EN 1.4547), S32053, S32615, S32654 (654 SMO, X1CrNiMoCuN24-22-8, EN 1.4652), S38815, N08020 (Alloy 20, EN 2.4660), N08028 (Alloy 28, Sanicro 28, EN 1.4563), N08029 (Sanicro 29), N08367 (AL-6XN), N08800, N08810, N08811, N08904 (904L, X1NiCrMoCu25-20-5, EN1.4539, Z2NCDU25-20), N08925 (Alloy 925), N08926 |

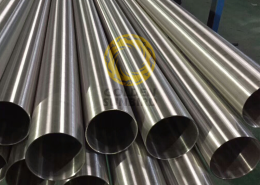

| Manufacturing Process | Hot Rolled, Cold Worked |

| Seam Type | Seamless and Welded |

| Dimension | Pipe OD: NPS 1/8″ – 48″ (10.3-1219.2mm), Pipe WT: SCH5S, 10S, 40S, 80S, XS, XXS |

| Length | 3000-12000mm |

| Delivery Condition | Solution Annealed, pickling |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical analysis, Tensile test, Intergranular corrosion test, Metallographic examination |

Packing

Both ends are plain or bevelled to an angle of 30°+5°/0° as per ANSI B16.25 and equipped with plastic pipe caps or bevel protectors. Small-diameter pipes are packaged in wooden crates, and large-diameter pipes are wrapped in woven bags.

Application

Downhole Tools and Wellhead Equipment: CRAs are used in the production tubing, casing, valves, and other components exposed to corrosive substances like hydrogen sulfide and carbon dioxide in crude oil and natural gas.

Pipelines and Piping Systems: These alloys are essential in constructing pipelines transporting corrosive fluids. They ensure long service life and reduce the risk of leaks and failures.

Engine Components: High-temperature alloys are critical in manufacturing parts of jet engines, including turbine blades and combustion chambers, where temperatures can exceed the melting points of common metals.

Structural Components: Alloys like titanium and nickel-based superalloys are used for their strength-to-weight ratio and resistance to atmospheric corrosion at high altitudes.

Reactors and Storage Tanks: CRAs are used in reactors, storage tanks, and other equipment that come into contact with acidic or basic chemicals, providing resistance to chemical attack and prolonging the equipment’s life.

Heat Exchangers and Condensers: They are used where high thermal conductivity and corrosion resistance are needed to manage high temperatures and aggressive chemical environments.

Boilers and Heat Exchangers: CRAs deal with high temperatures and corrosive by-products like sulfur compounds in power plants, particularly geothermal and coal-fired plants.

Turbine blades and other hot section components must withstand high temperatures and oxidative environments to achieve high efficiency.

Exhaust Systems: CRAs, including manifolds and converters, are used in exhaust systems to resist high temperatures and corrosive gases emitted during combustion.

Turbocharger Components: They must withstand the thermal fatigue and oxidation caused by high operating temperatures.

Propulsion Systems: Propeller shafts and turbine blades are made from CRAs to resist saltwater corrosion and erosion.

Offshore Structures: CRAs are critical in constructing offshore platforms and supporting vessels exposed to aggressive marine environments.