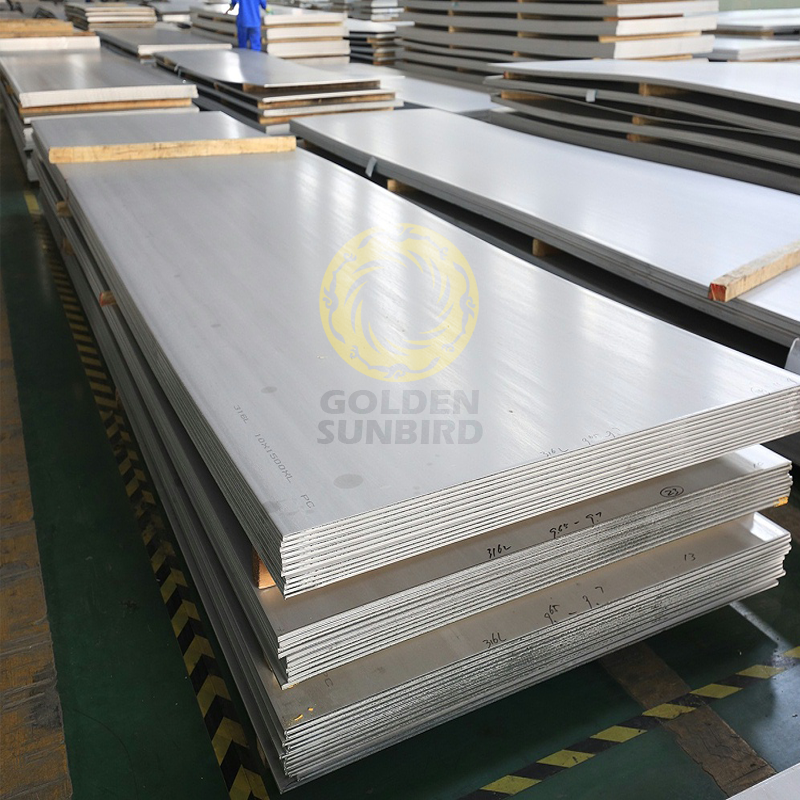

EN 10028-7 Stainless Steel Plate and Sheet for Pressure Purpose

- Grade: 1.4003, 1.4516, 1.4520, 1.4510, 1.4513, 1.4521, 1.4526, 1.4509, 1.4313, 1.4418, 1.4318, 1.4307, 1.4306, 1.4315, 1.4311, 1.4301, 1.4541, 1.4550, 1.4335, 1.4404, 1.4406, 1.4401, 1.4466, 1.4571, 1.4580, 1.4432, 1.4429, 1.4436, 1.4435, 1.4434, 1.4438, 1.4439, 1.4563, 1.4539, 1.4537, 1.4547, 1.4529, 1.4910, 1.4941, 1.4948, 1.4950, 1.4951, 1.4958, 1.4959, 1.4961, 1.4362, 1.4462, 1.4507, 1.4410, 1.4501

- Width: 1000-2500mm

- Length: 1000-12000mm

- Thickness: 1-100mm

Features

EN 10028-7 Stainless Steel Plate and Sheet for Pressure Purpose

Chemical Composition (wt.%)

| Designation | Chemical composition % by mass max unless stated | |||||||||

| Steel Name | Steel Number | C | Si | Mn | P | S | N | Cr | Mo | Ni |

| Ferritic stainless steels | ||||||||||

| X2CrNi12 | 1.4003 | 0.03 | 1 | 1.5 | 0.04 | 0.015 | 0.03 | 10.5/12.5 | – | 0.30/1.00 |

| X6CrNiTi12 | 1.4516 | 0.08 | 0.7 | 1.5 | 0.04 | 0.015 | – | 10.5/12.5 | – | 0.50/1.50 |

| X2CrTi17 | 1.4520 | 0.025 | 0.5 | 0.5 | 0.04 | 0.015 | 0.015 | 16.0/18.0 | – | – |

| X3CrTi17 | 1.4510 | 0.05 | 1 | 1 | 0.04 | 0.015 | – | 16.0/18.0 | – | – |

| X2CrMoTi17-1 | 1.4513 | 0.025 | 1 | 1 | 0.04 | 0.015 | 0.015 | 16.0/18.0 | 0.80/1.40 | – |

| X2CrMoTi18-2 | 1.4521 | 0.025 | 1 | 1 | 0.04 | 0.015 | 0.03 | 17.0/20.0 | 1.80/2.50 | – |

| X6CrMoNb17-1 | 1.4526 | 0.08 | 1 | 1 | 0.04 | 0.015 | 0.04 | 16.0/18.0 | 0.80/1.40 | – |

| X2CrTiNb18 | 1.4509 | 0.03 | 1 | 1 | 0.04 | 0.015 | – | 17.5/18.5 | – | – |

| Martensitic stainless steels | ||||||||||

| X3CrNiMo13-4 | 1.4313 | 0.05 | 0.7 | 1.5 | 0.04 | 0.015 | >0.020 | 12.0/14.0 | 0.30/0.70 | 3.5/4.5 |

| X4CrNiMo16-5-1 | 1.4418 | 0.06 | 0.7 | 1.5 | 0.04 | 0.015 | >0.020 | 15.0/17.0 | 0.80/1.50 | 4.0/6.0 |

| Austenitic stainless steels | ||||||||||

| X2CrNiN18-7 | 1.4318 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.10/0.20 | 16.5/18.5 | – | 6.0/8.0 |

| X2CrNi18-9 | 1.4307 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 17.5/19.5 | – | 8.0/10.5 |

| X2CrNi19-11 | 1.4306 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 18.0/20.0 | – | 10.0/12.0 |

| X5CrNiN19-9 | 1.4315 | 0.06 | 1 | 2 | 0.045 | 0.015 | 0.12/0.22 | 18.0/20.0 | – | 8.0/11.0 |

| X2CrNiN18-10 | 1.4311 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.12/0.22 | 17.5/19.5 | – | 8.5/11.5 |

| X5CrNi18-10 | 1.4301 | 0.07 | 1 | 2 | 0.045 | 0.015 | 0.11 | 17.5/19.5 | – | 8.0/10.5 |

| X6CrNiTi18-10 | 1.4541 | 0.08 | 1 | 2 | 0.045 | 0.015 | – | 17.0/19.0 | – | 9.0/12.0 |

| X6CrNiNb18-10 | 1.4550 | 0.08 | 1 | 2 | 0.045 | 0.015 | – | 17.0/19.0 | – | 9.0/12.0 |

| X1CrNi25-21 | 1.4335 | 0.02 | 0.25 | 2 | 0.025 | 0.01 | 0.11 | 24.0/26.0 | 0.2 | 20.0/22.0 |

| X2CrNiMo17-12-2 | 1.4404 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 16.5/18.5 | 2.00/2.50 | 10.0/13.0 |

| X2CrNiMoN17-11-2 | 1.4406 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.12/0.22 | 16.5/18.5 | 2.00/2.50 | 10.0/12.0 |

| X5CrNiMo17-12-2 | 1.4401 | 0.07 | 1 | 2 | 0.045 | 0.015 | 0.11 | 16.5/18.5 | 2.00/2.50 | 10.0/13.0 |

| X1CrNiMoN25-22-2 | 1.4466 | 0.02 | 0.7 | 2 | 0.025 | 0.01 | 0.10/0.16 | 24.0/26.0 | 2.00/2.50 | 21.0/23.0 |

| X6CrNiMoTi17-12-2 | 1.4571 | 0.08 | 1 | 2 | 0.045 | 0.015 | – | 16.5/18.5 | 2.00/2.50 | 10.5/13.5 |

| X6CrNiMoNb17-12-2 | 1.4580 | 0.08 | 1 | 2 | 0.045 | 0.015 | – | 16.5/18.5 | 2.00/2.50 | 10.5/13.5 |

| X2CrNiMo17-12-3 | 1.4432 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 16.5/18.5 | 2.50/3.00 | 10.5/13.0 |

| X2CrNiMoN17-3-3 | 1.4429 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.12/0.22 | 16.5/18.5 | 2.50/3.00 | 11.0/14.0 |

| X3CrNiMo17-13-3 | 1.4436 | 0.05 | 1 | 2 | 0.045 | 0.015 | 0.11 | 16.5/18.5 | 2.50/3.00 | 10.5/13.0 |

| X2CrNiMo18-14-3 | 1.4435 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 17.0/19.0 | 2.50/3.00 | 12.5/15.0 |

| X2CrNiMoN18-12-4 | 1.4434 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.10/0.20 | 16.5/19.5 | 3.0/4.0 | 10.5/14.0 |

| X2CrNiMo18-15-4 | 1.4438 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.11 | 17.5/19.5 | 3.0/4.0 | 13.0/16.0 |

| X2CrNiMoN17-13-5 | 1.4439 | 0.03 | 1 | 2 | 0.045 | 0.015 | 0.12/0.22 | 16.5/18.5 | 4.0/5.0 | 12.5/14.5 |

| X1NiCrMo31-27-4 | 1.4563 | 0.02 | 0.7 | 2 | 0.03 | 0.01 | 0.11 | 26.0/28.0 | 3.0/4.0 | 30.0/32.0 |

| X1NiCrMoCu25-20-5 | 1.4539 | 0.02 | 0.7 | 2 | 0.03 | 0.01 | 0.15 | 19.0/21.0 | 4.0/5.0 | 24.0/26.0 |

| X1CrNiMoCuN25-25-5 | 1.4537 | 0.02 | 0.7 | 2 | 0.03 | 0.01 | 0.17/0.25 | 24.0/26.0 | 4.7/5.7 | 24.0/27.0 |

| X1CrNiMoCuN20-18-7 | 1.4547 | 0.02 | 0.7 | 1 | 0.03 | 0.01 | 0.18/0.25 | 19.5/20.5 | 6.0/7.0 | 17.5/18.5 |

| X1NiCrMoCuN25-20-7 | 1.4529 | 0.02 | 0.5 | 1 | 0.03 | 0.01 | 0.15/0.25 | 19.0/21.0 | 6.0/7.0 | 24.0/26.0 |

| Austenitic creep resisting steels | ||||||||||

| X3CrNiMoBN17-13-3 | 1.4910 | 0.4 | 0.75 | 2 | 0.035 | 0.015 | 0.10/0.18 | 16.0/18.0 | 2.00/3.00 | 12.0/14.0 |

| X6CrNiTiB18-10 | 1.4941 | 0.04/0.08 | 1 | 2 | 0.035 | 0.015 | – | 17.0/19.0 | – | 9.0/12.0 |

| X6CrNi18-10 | 1.4948 | 0.04/0.08 | 1 | 2 | 0.035 | 0.015 | 0.1 | 17.0/19.0 | – | 8.0/11.0 |

| X6CrNi23-13 | 1.4950 | 0.04/0.08 | 0.7 | 2 | 0.035 | 0.015 | 0.1 | 22.0/24.0 | – | 12.0/15.0 |

| X6CrNi25.20 | 1.4951 | 0.04/0.08 | 0.7 | 2 | 0.035 | 0.015 | 0.1 | 24.0/26.0 | – | 19.0/22.0 |

| X5NiCrAlTi31-20 | 1.4958 (+RA) | 0.03/0.08 | 0.7 | 1.5 | 0.015 | 0.01 | 0.03 | 19.0/22.0 | – | 30.0/32.5 |

| X8NiCrAlTi32-21 | 1.4959 | 0.05/0.10 | 0.7 | 1.5 | 0.015 | 0.01 | 0.03 | 19.0/22.0 | – | 30.0/34.0 |

| X8CrNiNb16-13 | 1.4961 | 0.04/0.10 | 0.30/0.60 | 1.5 | 0.035 | 0.015 | – | 15.0/17.0 | – | 12.0/14.0 |

| Austenitic-ferritic stainless steels | ||||||||||

| X2CrNiN23-4 | 1.4362 | 0.03 | 1 | 2 | 0.035 | 0.015 | 0.05/0.20 | 22.0/24.0 | 0.10/0.60 | 3.5/5.5 |

| X2CrNiMoN12-5-3 | 1.4462 | 0.03 | 1 | 2 | 0.035 | 0.015 | 0.10/0.22 | 21.0/23.0 | 2.50/3.50 | 4.5/6.5 |

| X2CrNiMoCuN25-6-3 | 1.4507 | 0.03 | 0.7 | 2 | 0.035 | 0.015 | 0.20/0.30 | 24.0/26.0 | 3.0/4.0 | 6.0/8.0 |

| X2CrNiMoN25-7-4 | 1.4410 | 0.03 | 1 | 2 | 0.035 | 0.015 | 0.24/0.35 | 24.0/26.0 | 3.0/4.5 | 6.0/8.0 |

| X2CrNiMoCuWN25-7-4 | 1.4501 | 0.03 | 1 | 1 | 0.035 | 0.015 | 0.20/0.30 | 24.0/26.0 | 3.0/4.0 | 6.0/8.0 |

Technical Specifications

| Specification | Value |

| Standard | EN 10028-7 Stainless Steel Plate and Sheet for Pressure Purpose |

| Grade | 1.4003, 1.4516, 1.4520, 1.4510, 1.4513, 1.4521, 1.4526, 1.4509, 1.4313, 1.4418, 1.4318, 1.4307, 1.4306, 1.4315, 1.4311, 1.4301, 1.4541, 1.4550, 1.4335, 1.4404, 1.4406, 1.4401, 1.4466, 1.4571, 1.4580, 1.4432, 1.4429, 1.4436, 1.4435, 1.4434, 1.4438, 1.4439, 1.4563, 1.4539, 1.4537, 1.4547, 1.4529, 1.4910, 1.4941, 1.4948, 1.4950, 1.4951, 1.4958, 1.4959, 1.4961, 1.4362, 1.4462, 1.4507, 1.4410, 1.4501 |

| Manufacturing Process | Hot Rolled, Cold Rolled |

| Type | Plate and Sheet |

| Dimension | Thickness: 1-100mm Width: 1000mm, 1219mm, 1250mm, 1500mm, 2000mm, 2200mm, 2500mm Length: 1000mm, 2438mm, 3000mm, 6000mm, 12000mm |

| Other requirements | Upon customer’s request or size availability |

| Delivery Condition | Solution, pickling, straightening and trimming. |

| Inspection Certificate | EN 10204 Type 3.1 (Mill Test Certificate), EN 10204 Type 3.2 (Witness Testing or 3rd Party Inspection) |

| Tests | Chemical analysis, Tensile test, Intergranular corrosion test, Metallographic examination |

Packing

Packed on plywood pallets.

Application

Pressure Vessels and Boilers: Fabricating components that require high strength and resistance to pressure and heat.

Heat Exchangers: Essential for efficient thermal transfer in various industries.

Chemical and Petrochemical Industries: Applied in constructing reactors, separators, and storage tanks that handle corrosive substances.

Food Processing and Pharmaceutical Equipment: Ensures hygiene and resistance to various chemicals.

Storage Tanks: Suitable for storing both liquids and gases under pressure due to their durability and resistance to corrosion.